Enfoque metodológico para el aprovechamiento de mermas de transformación agrícola basado en manufactura esbelta: Caso de estudio en una finca cafetera en Colombia

DOI:

https://doi.org/10.17268/sci.agropecu.2024.028Palavras-chave:

agricultura esbelta, mermas de agricultura, mejora de procesos, proceso de transformación, compostajeResumo

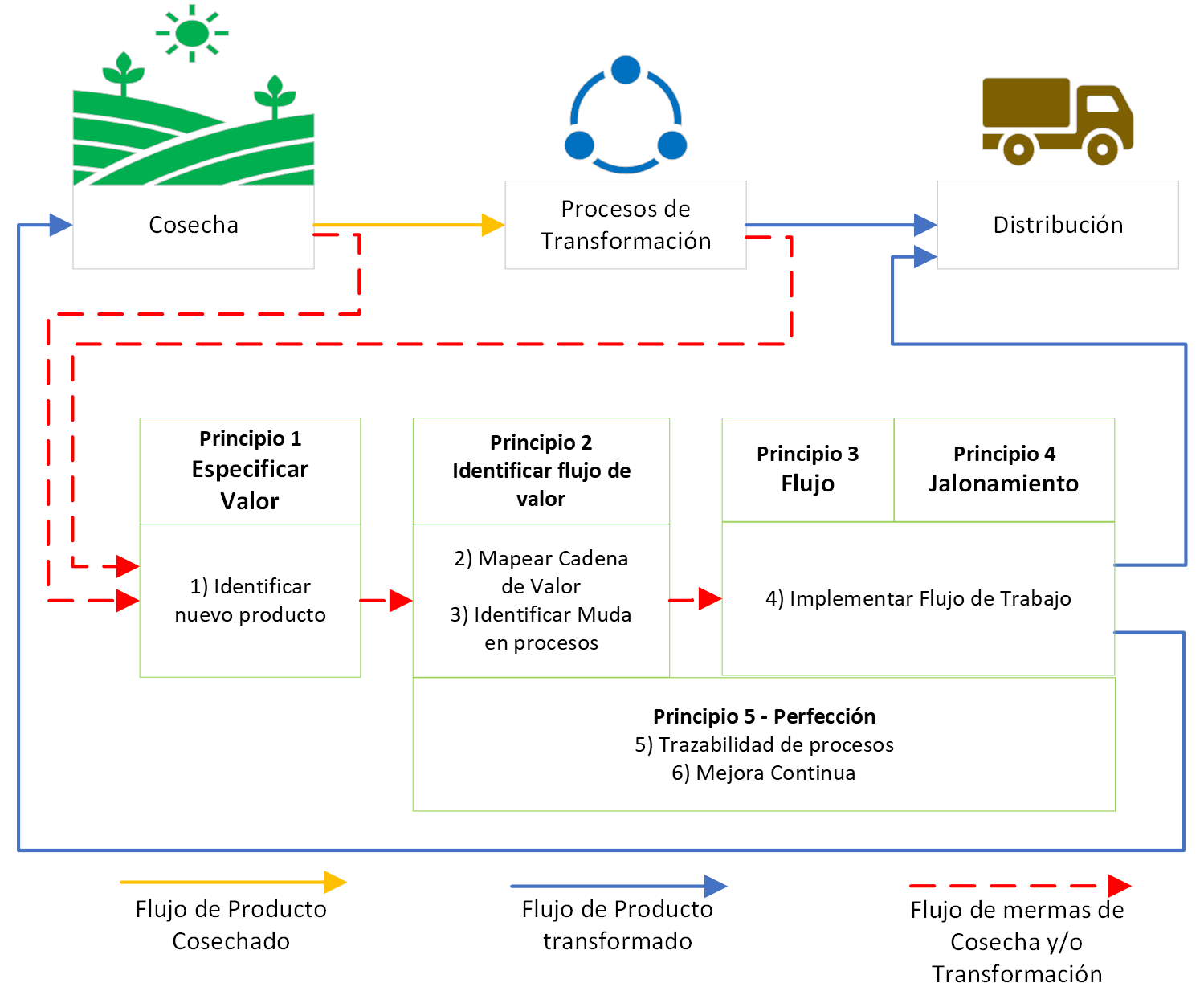

Las mejoras en sistemas productivos que utilizan el enfoque de manufactura esbelta conocido como “Lean” tienen el objetivo de eliminar o reducir desperdicios o ineficiencias de proceso (muda). Este enfoque es adoptado por diferentes sectores industriales, entre ellos el agrícola de manera reciente. Aunque tradicionalmente se aplican mejoras Lean en procesos ya existentes desde el cultivo hasta la distribución, se dejan de lado oportunidades de intervención de pérdidas de procesamiento (mermas). Este artículo presenta un enfoque metodológico enmarcado en principios Lean, conformado por actividades orientadas al diseño de nuevos procesos que dan uso de las mermas generadas por cosecha y transformación agrícola. Se aplica el enfoque metodológico en una finca cafetera colombiana en la que se desarrollan procesos de transformación de café pergamino. Se diseña un proceso paralelo de compostaje de mermas que transforma granos defectuosos, verdes, sobremaduros, pulpa de café, mucilago y cascarilla. Los resultados demuestran que al aplicar el enfoque metodológico en la finca cafetera se logra un nivel de transformación de mermas del 86%. También se reducen las muda tanto para la línea actual de producción de café pergamino como la de compostaje al 35% y 50% respectivamente. Las principales muda reducidas son reprocesos y tiempos de espera. Finalmente se obtiene una reducción del 30,3% en el tiempo de actividades que no agregan valor haciendo de los procesos tanto actual como propuesto más eficientes y con mejores tiempos de entrega.

Referências

Andersson, K., Eklund, J., & Rydberg, A. (2020). Lean Inspired development work in agriculture: Implications for the work environment. Agronomy Research, 18(2), 324-345. doi.org/10.15159/AR.20.043.

Barth, H., & Melin, M. (2018). A green lean approach to global competition and climate change in the agricultural sector: A Swedish case study. Journal of cleaner production, 204, 183-192. doi.org/10.1016/j.jclepro.2018.09.021.

Baumont, F., Forbes, H., Schaefer, D., & Milisavljevic, J. (2020). Lean Principles in vertical farming: A Case study. 53rd Conference on Manufacturing Systems. Chicago: Procedia CIRP.

Bella, I., Danusaputro, S., & Nurprihatin, F. (2024). The implementation of Lean Six Sigma approach to minimize waste at a food manufacturing industry. Journal of Engineering Research, https://doi.org/10.1016/j.jer.2024.01.022.

Bicheno, J. (2004). The New Lean Toolbox: Towards Fast, Flexible, Flow. Buckingham, UK.: Moreton Press.

Bohorquez, W. (2019). The composting process. Bogotá, Colombia: Unisalle Editions. ISBN 978-958-5486-67-6.

Caicedo, N., Garcia, G., & Montoya, J. (2019). Towards the integration of lean principles and optimization for agricultural production systems: A conceptual review proposition. Science of Food and Agriculture, 100(2), 453-464. https://doi.org/10.1002/jsfa.10018.

Caicedo, N., Garcia, G., Montoya, J., & Ramirez, L. (2020). A planning model of crop maintenance operations inspired in lean manufacturing. Computers and electronics in Agriculture, 179, 105852. https://doi.org/10.1016/j.compag.2020.105852.

Chairany, N., Hidayatno, A., & Suzianti, A. (2022). Risk Analysis Approach to Identifying Actions that Reduce Waste for a Lean Agricultural Supply Chain. Journal of Industrial Engineering and Management, 15(2), 350-366. https://doi.org/10.3926/jiem.3678.

Chavez, J., Osorio, F., Dominguez, F., Raymundo, C., & Altamirano, E. (2019). Lean production management model for SME waste reduction in the processed food sector in Peru. International Conference on Applied Human Factors and Ergonomics. San Diego: Springer.

Czekala, W., Lukomska, A., Pulka, J., Bojarski, W., Pochwatka, P., Kowalczyk, A., Oniszczuk, A., & Dach, J. (2023). Waste to energy: Biogas potential of waste from coffee production and consumption. Energy, 276, 127604. https://doi.org/10.1016/j.energy.2023.127604.

FAO. (2011). Global Food Losses and Food Waste. Retrieved from http://www.fao.org/3/i2697e/i2697e.pdf.

Fladkjaer, V., & Pejstrup, S. (2018). Lean in Agriculture: Create More Value with less work on the farm. Routledge. Taylor & Francis Group.

Forrester, P., Kazumi, U., Soriano, H., Garza, J., & Cruz, L. (2010). Lean production, market share and value creation in the agricultural machinery sector in Brazil. Journal of Manufacturing Technology Management, 21(7), 853-871. DOI: 10.1108/17410381011077955.

Gonzalez, F., Huaman, V., Sotelo, F., & Ramos, E. (2020). Applying Lean Agriculture in Organic Apple Production: Case Study in Peru. Human Interaction, Emerging Technologies and Future Applications IHIET. Paris: Advances in Intelligent Systems and Computing. Springer.

Hartman, B. (2015). The Lean Farm: How to minimize waste, increase efficiency an maximize value and profits with less work. Chelsea Green.

Hoseini, M., Cocco, S., Casucci, C., Cardelli, V., & Corti, G. (2021). Coffee by products derived: A review. Biomass and Bioenergy, 148, 106009. https://doi.org/10.1016/j.biombioe.2021.106009.

Hualpa, A., & Rangel, J. (2023). Traceability in the agricultural sector: A review for the period 2017-2022. Agronomia Mesoamericana, 34(2), 51828. DOI: 10.15517/am.v34i2.51828.

Lermen, F., Echeveste, M., Peralta, C., Sonego, M., & Marcon, A. (2018). A framework for selecting lean practices in sustainable product development: The case study of a brazilian agroindustry. Journal of Cleaner Production, 191, 261-272. DOI: 10.1016/j.jclepro.2018.04.185.

Manrique, S., Sabogal, K., Sotelo, F., & Ramos, E. (2018). Modelo of quality management applied in lean green agriculture methodology: A research in Perú. 18th LACCEI International Multi Conference for Engineering, Education and Technology. Florida, USA: Virtual Eition.

Martins, A., dos Anjos, F., & da Silva, D. (2023). The Lean Farm: Aplication of tools and concepts of lean manufacturing in agropastoral crops. Sustainability, 15(3), 2597. https://doi.org/10.3390/su15032597.

Melin, M., & Barth, H. (2018). Lean in swedish agriculture: strategic and operational perspectives. Production Planning & Control, 29(10), 845-855. DOI: 10.1080/09537287.2018.1479784.

Melin, M., & Barth, H. (2020). Value Stream mapping for sustainable change at a Swedish dairy farm. Environment and waste management, 25(1), 130-140. DOI:10.1504/IJEWM.2020.104367.

Parffit, J., Macnaughton, S., & Barthel, M. (2010). Food waste within food supply chains: Quantification and potential for chage to 2050. Philosophical Transactions of the Royal Society Biological Sciencies, 365, 3065-3081. https://doi.org/10.1098/rstb.2010.0126.

Pearce, D., Dora, M., Wesana, J., & Gellynck, X. (2021). Toward sustainable primary production through the application of lean management in South African fruit horticulture. Journal of Cleaner Production, 313, 127815. https://doi.org/10.1016/j.jclepro.2021.127815.

Perdana, T., Sadeli, A., Hermiatin, F., & Ginanjar, T. (2019). Lean management in the rice industry: case study at Widasari, Indramayu District. IOP Conf: Earth and Environmental Science. IOP Publishing.

Saaty, T. (2008). Relative measurement and its generalization in decision making: Why pairwise comparisons are central in mathematics for the measurement of intangible factors. Royal Spanish Academy of Sciences, 102(2), 251-318. https://doi.org/10.1007/BF03191825.

Vinicius, L., Mahlmann, L., Giraldo, F., Hofmann, N., Frozza, R., Aldana, S., & Taborda, C. (2018). A model for Lean and Green integration and monitoring for the coffee sector. Computers and Electronics in Agriculture, 62-73. https://doi.org/10.1016/j.compag.2018.03.034.

Womack, J., Jones, D., & Roos, D. (1991). The machine that changed the world: The Story of lean production. Harper Collins.

Publicado

Como Citar

Edição

Seção

Licença

Copyright (c) 2024 Scientia Agropecuaria

Este trabalho está licenciado sob uma licença Creative Commons Attribution-NonCommercial 4.0 International License.

Los autores que publican en esta revista aceptan los siguientes términos:

a. Los autores conservan los derechos de autor y conceden a la revista el derecho publicación, simultáneamente licenciada bajo una licencia de Creative Commons que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

b. Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

c. Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (ver efecto del acceso abierto).