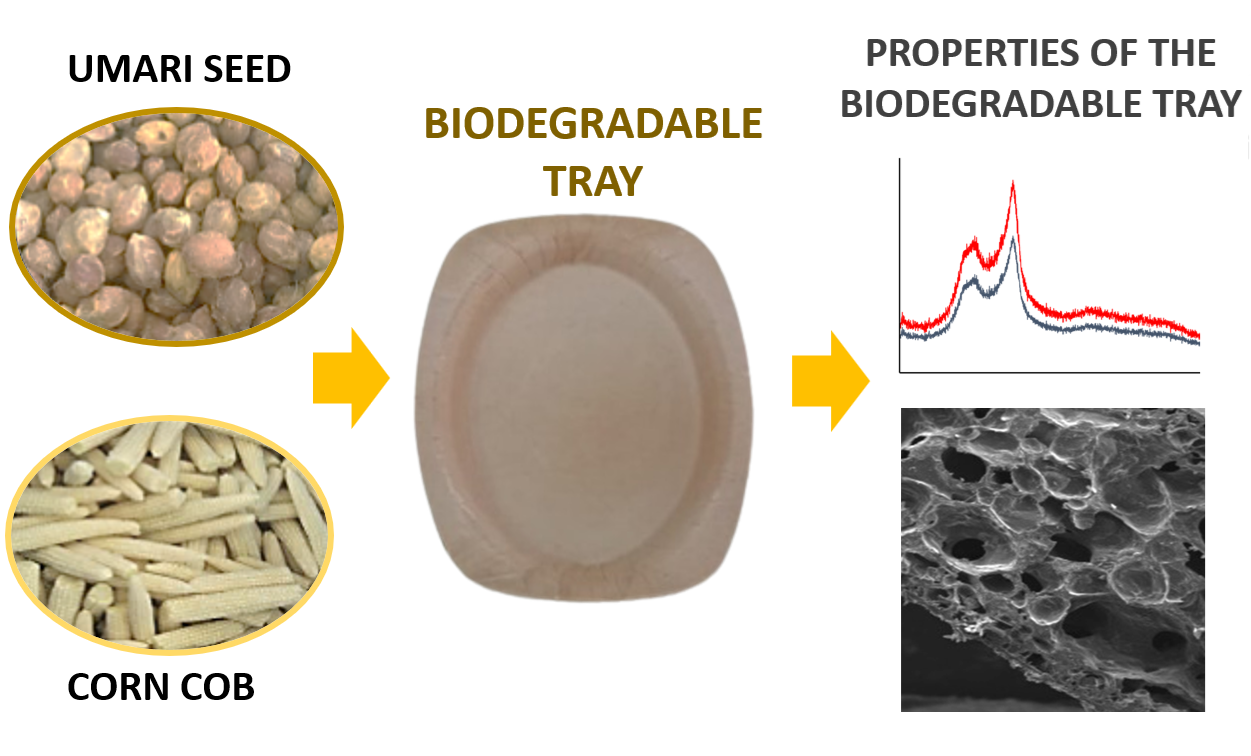

Biodegradable trays made from Poraqueiba sericea Tulasne seed starch and Zea mays cob flour

DOI:

https://doi.org/10.17268/sci.agropecu.2025.002Palabras clave:

biodegradable tray, corn cob, umari seed, starch, fiberResumen

The environmental impact of polystyrene and other petrochemical packaging has increased interest in researching biodegradable materials as alternatives. The main objective of this research was to develop biodegradable trays from five formulations of Poraqueiba sericea Tulasne (known as umari) seed starch and corncob meal. The trays were produced using the thermoforming process applying temperatures of 135 °C and 145 °C for each side of the tray for a time of 6.5 min. Physical analysis of the trays showed that the increase in the percentage of corn cob flour caused changes in color (L*: 68.69 - 64.94), thickness (2.20 - 3.17 mm), density (0.251 - 0.414 g/cm3), moisture (3.85% - 5.68%), water absorption (21.86% - 39.05%), volatile solids (95.33% - 98.31%). Regarding mechanical properties, it was also evidenced the increase in hardness (67.70 - 90.97 N), fracturability (1.43 and 3.19 mm), tension (2.84 to 3.43 MPa) and elongation (1.54% to 2.04%). The formulation of 87.5% umari seed starch and 12.5% corncob flour presented more favorable physical and mechanical properties. Further analysis of this formulation was performed by Fourier transform infrared spectroscopy (FTIR), which identified bands characteristic of starch (1055 and 1027 cm-1); X-ray diffraction (XRD), which revealed characteristic peaks (2θ = 16.83° and 2θ = 22.69°) associated with cellulose crystallinity in the biodegradable tray; and scanning electron microscopy (SEM), which revealed cellulosic voids with irregular distribution due to the addition of fibers. Future research should examine the potential applications of these biodegradable trays for the packaging of raw materials in the food industry.

Citas

Aguilar, R., Valiente, Y., Oliver, D., Franco, C., Méndez, F., Luna, C., & Diaz, F. (2018). Inadecuado uso de residuos sólidos y su impacto en la contaminación ambiental. SCIÉNDO, 21(4), 401-407. https://doi.org/10.17268/sciendo.2018.044

Aguirre, E., Dominguez, J., Villanueva, E., Ponce, R., Arevalo, O., Siche, R., González, C., & Rodríguez, G. (2023). Biodegradable trays based on Manihot esculenta Crantz starch and Zea mays husk flour. Food Packaging and Shelf Life, 38, 101129. https://doi.org/10.1016/j.fpsl.2023.101129

Bergel, B. F., Dias Osorio, S., Da Luz, L. M., & Santana, R. M. C. (2018). Effects of hydrophobized starches on thermoplastic starch foams made from potato starch. Carbohydrate Polymers, 200, 106–114. https://doi.org/10.1016/j.carbpol.2018.07.047

Bergel, B.F., da Luz L.M., & Santana, R.M.C. (2017). Comparative study of the influence of chitosan as coating of thermoplastic starch foam from potato, cassava and corn starch. Prog Org Coat, 106, 27–32. https://doi.org/10.1016/j.porgcoat.2017.02.010

Berto, A., da Silva, A.F., Visentainer, J.V., Matsushita, M., & de Souza, N.E. (2015). Proximate compositions, mineral contents and fatty acid compositions of native Amazonian fruits, Food Research International, 77, 441–449. https://doi.org/10.1016/J.FOODRES.2015.08.018.

Bhatia, S.K., Jagtap, S.S., Bedekar, A.A., Bhatia, R.K., Patel, A.K., Pant, D., Banu, J.R., Rao, C.V., Kim, Y.-G., & Yang, Y.-H. (2020). Recent developments in pretreatment technologies on lignocellulosic biomass: Effect of key parameters, technological improvements, and challenges. Bioresour. Technol, 300, 122724. https://doi.org/10.1016/j.biortech.2019.122724

Bovo, M., Giani, N., Barbaresi, A., Mazzocchetti, L., Barbaresi, L., Giorgini, L., Torreggiani, D., & Tassinari, P. (2022). Contribution to thermal and acoustic characterization of corn cob for bio-based building insulation applications. Energy and Buildings, 262, 111994. https://doi.org/10.1016/j.enbuild.2022.111994

Cabanillas, A., Nuñez, J., Cruz-Tirado, J., Vejarano, R., Tapia-Blácido, D., Arteaga, H., & Siche, R. (2019). Pineapple shell fiber as reinforcement in cassava starch foam trays. Polymers and Polymer Composites, 27(8), 496-506. https://doi.org/10.1177/0967391119848187

Cheng, Z., Li, J., He, G., Su, M., Xiao, N., Zhang, X., Zhong, L., Wang, H., Zhong, Y., Chen, Q., Chen, Y., & Liu, M. (2024). Biodegradable packaging paper derived from chitosan-based composite barrier coating for agricultural products preservation. International Journal of Biological Macromolecules, 136112. https://doi.org/10.1016/j.ijbiomac.2024.136112

Cruz, R. (2021). Effect of the proportion of fiber and starch obtained from the banana pseudostem (Musa acuminata) on the properties of biodegradable trays. [Tesis para optar el grado de Ingeniero]. Trujillo, Perú: Universidad Nacional de Trujillo. https://renati.sunedu.gob.pe/handle/sunedu/2992267

Cruz-Tirado, J. P., Siche, R., Cabanillas, A., Díaz-Sánchez, L., Vejarano, R., & Tapia- Blácido, D. R. (2017). Properties of baked foams from oca (Oxalis tuberosa) starch reinforced with sugarcane bagasse and asparagus peel fiber. Procedia Engineering, 200, 178-185. https://doi.org/10.1016/j.proeng.2017.07.026

Cruz-Tirado, J. P., Vejarano, R., Tapia, B., Barraza, J., & Siche, R. (2019). Biodegradable foam tray based on starches isolated from different Peruvian species. International journal of biological macromolecules, 125, 800-807. https://doi.org/10.1016/j.ijbiomac.2018.12.111

De Dios-Avila, N., Tirado-Gallegos, J. M., Estrada-Virgen, M. O., Rios-Velasco, C., Luna-Esquivel, G., Zamudio-Flores, P. B., Isiordia-Aquino, N., & Campos, O. J. C. (2022). Structural and physicochemical characterization of avocado seed starches modified by high-temperature acid hydrolysis. Revista Bio Ciencias, 9. https://doi.org/10.15741/revbio.09.e1272

Días, J. F., & Acuña, J. G. (2022). Uso de almidón para el desarrollo de bandejas biodegradables. Journal of Agro-Industry. Sciences, 4(2), 69–77.

Ediyilyam, S., George, B., Shankar, S. S., Dennis, T. T., Wacławek, S., Černík, M., & Padil, V. V. T. (2021). Películas compuestas de nanopartículas de quitosano, gelatina y plata para aplicaciones de envasado de alimentos biodegradables. Polymers, 13(11), 1680. https://doi.org/10.3390/polym13111680

El Menofy, N. G., & Khattab, A. M. (2023). Plastics Biodegradation and Biofragmentation. In: Ali, G.A.M., Makhlouf, A.S.H. (eds) Handbook of Biodegradable Materials. Springer, Cham. https://doi.org/10.1007/978-3-031-09710-2_22

Emadian, S. M., T.Onay, T., & Demirel, B. (2017). Biodegradation of bioplastics in natural environments. Waste Management, 59, 526-536. https://doi.org/10.1016/j.wasman.2016.10.006

Ferreira, D., Molina, G., & Pelissari, F. (2020). Biodegradable trays based on cassava starch blended with agroindustrial residues. Composites Part B: Engineering, 183, 107682. https://doi.org/10.1016/j.compositesb.2019.107682

Freitas, L. C., Sousa Cantão, M. B., Carvalho, V. S., Silva dos Santos, R. W., Corazza, M. L., & Masson, M. L. (2024). Compressed n-propane extraction of umari pulp oil: A rich Amazon source of β-carotene and omega-9. The Journal of Supercritical Fluids, 213, 106369, https://doi.org/10.1016/j.supflu.2024.106369.

Gandam, P. K., Chinta, M. L., Gandham, A. P., Pabbathi, N. P. P., Konakanchi, S., Bhavanam, A., Atchuta, S. R., Baadhe, R. R., & Bhatia, R. K. (2022). A New Insight into the Composition and Physical Characteristics of Corncob—Substantiating Its Potential for Tailored Biorefinery Objectives. Fermentation, 8, 704. https://doi.org/10.3390/fermentation8120704

Ismail, S. A., Nour, S. A., & Hassan, A. A. (2022). Valorization of corn cobs for xylanase production by Aspergillus flavus AW1 and its application in the production of antioxidant oligosaccharides and removal of food stain. Biocatalysis and Agricultural Biotechnology, 41, 102311. https://doi.org/10.1016/j.bcab.2022.102311

Kaisangsri, N., Kerdchoechuen, O., & Laohakunjit, N. (2014). Characterization of cassava starch-based foam blended with plant proteins, kraft fiber, and palm oil. Carbohydr Polym, 110, 70–77. https://doi.org/10.1016/j.carbpol.2014.03.067

Kumar, N. P., & Saha, N. D. (2021). Drying Kinetics of Maize Cob Using Mathematical Modelling. Journal of Agricultural Engineering (India), 58(1), 40-49. https://doi.org/10.52151/jae2021581.1733

Lawton, J. W., Shogren, R. L. & Tiefenbacher, K. F. (1999). Effect of batter solids and starch 109 type on the structure of baked starch foams. Cereal Chemistry, 76(5), 682–687. https://doi.org/10.1094/CCHEM.1999.76.5.682

Li, S., Wang, Y., Xu, W., & Shi, B. (2020). Natural Rubber-Based Elastomer Reinforced by Chemically Modified Multiscale Leather Collagen Fibers with Excellent Toughness. ACS Sustainable Chemistry & Engineering, 8(13), 5091-5099. https://doi.org/10.1021/acssuschemeng.9b07078

Machado, C., Benelli, P., & Tessaro, I. (2017). Sesame cake incorporation on cassava starch foams for packaging use. Industrial Crops and Products, 102, 115-121. https://doi.org/10.1016/j.indcrop.2017.03.007

Machado, C. M., Benelli, P., & Tessaro, I. C. (2020). Study of interactions between cassava starch and peanut skin on biodegradable foams. International Journal of Biological Macromolecules, 147, 1343–1353. https://doi.org/10.1016/j.ijbiomac.2019.10.098

Marengo, V., Vercelheze, A. & Mali, S. (2013). Biodegradable composites based on cassava starch and waste from Agro-Industry. Quimica Nova, 36(5), 680-685.

Meijer, L. J. J., Van Emmerik, T., Van Der Ent, R., Schmidt, C., & Lebreton, L. (2021). More than 1000 rivers account for 80% of global riverine plastic emissions into the ocean. Science Advances, 7(18), eaaz5803. https://doi.org/10.1126/sciadv.aaz5803

Mello, L., & Mali, S. (2014). Use of malt bagasse to produce biodegradable baked foams made from cassava starch. Industrial Crops and Products, 55, 187-193. https://doi.org/10.1016/j.indcrop.2014.02.015

Moshood, T. D., Nawanir, G., Mahmud, F., Mohamad, F., Ahmad, M. H., & AbdulGhani, A. (2022). Biodegradable plastic applications towards sustainability: A recent innovations in the green product. Cleaner Engineering and Technology, 6, 100404. https://doi.org/10.1016/j.clet.2022.100404

Oliveira, R., Bonametti, O., Bilcka, A., Zanelac J., Grossmanna, E., & Yamashitaa, F. (2018). Biodegradable trays of thermoplastic starch/poly (lactic acid) coated with beeswax. Industrial Crops & Products, 112, 481 – 487.

Onyeaka, H., Obileke, K., Makaka, G., & Nwokolo, N. (2022). Current Research and Applications of Starch-Based Biodegradable Films for Food Packaging. Polymers, 14(6), 1126. https://doi.org/10.3390/polym14061126

Ordoñéz, P., Aguirre, V., Flores, J. (2001). Aprovechamiento integral del umarí (Poraqueiba sericea Tulasne) en la industria de alimentos. Revista Amazónica de Investigación Alimentaria, 1(1), 30 – 37.

Pandey, P., Dhiman, M., Kansal, A., & Subudhi, S.P. (2023). Plastic waste management for sustainable environment: techniques and approaches. Waste Dispos Sustain Energy, 6,1-18. https://doi.org/10.1007/s42768-023-00134-6

Silva, M. de L., Silva, W. J. dos S., & Pereira, A. K. L. S. (2020). Aproveitamento de resíduos vegetais como alternativa na fabricação de embalagens biodegradáveis / Use of vegetable waste as an alternative in the manufacture of biodegradable packaging. Brazilian Journal of Development, 6(11), 86238–86250. https://doi.org/10.34117/bjdv6n11-155

Silva, N. A. C. (1997). Caracterización de los aceites crudo, neutro y decolorado de la pulpa y cascara de la fruta silvestre Paraqueiba serices Tulasne «UMARI». Grasas y Aceites, 48, 11–16. https://doi.org/10.3989/gya.1997.v48.i1.769.

Tapia-Blácido, D. R., Aguilar, G. J., De Andrade, M. T., Rodrigues-Júnior, M. F., & Guareschi-Martins, F. C. (2021). Trends and challenges of starch-based foams for use as food packaging and food container. Trends In Food Science & Technology, 119, 257-271. https://doi.org/10.1016/j.tifs.2021.12.005

USDA. (2024). Department of Agriculture. (n.d.). Production – com. https://fas.usda.gov/data/production/commodity/0440000

Vercelheze, A., Oliveira, A., Rezende, M., Muller, C., Yamashita, F., & Mali, S. (2013). Physical Properties, Photo- and Bio-degradation of Baked Foams Based on Cassava Starch, Sugarcane Bagasse Fibers and Montmorillonite. Journal of Polymers and the Environment, 21(1), 266-274. https://doi.org/10.1007/s10924-012-0455-0

Vercelheze, A. E. S., Fakhouri, F. M., Dall'Antonia, L. H., Urbano, A., Youssef, E. Y., Yamashita, F., & Mali, S. (2012). Properties of baked foams based on cassava starch, sugarcane bagasse fibers and montmorillonite. Carbohydr Polym, 87(2), 1302–1310. https://doi.org/10.1016/j.carbpol.2011.09.016

Villanueva, E., Glorio-Paulet, P., Giusti, M.M., Sigurdson, G.T., Yao, S., & Rodríguez-Saona, L.E. (2023). Screening for pesticide residues in cocoa (Theobroma cacao L.) by portable infrared spectroscopy. Talanta, 257, 124386, https://doi.org/10.1016/j.talanta.2023.124386

Zhu, L., Zhu, J., Zuo, R., Xu, Q., Qian, Y., & An, L. (2022). Identification of microplastics in human placenta using laser direct infrared spectroscopy. The Science of the Total Environment, 856, 159060. https://doi.org/10.1016/j.scitotenv.2022.159060

Zwawi, M. (2021). A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules, 26(2), 404. https://doi.org/10.3390/molecules26020404

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2024 Scientia Agropecuaria

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial 4.0.

Los autores que publican en esta revista aceptan los siguientes términos:

a. Los autores conservan los derechos de autor y conceden a la revista el derecho publicación, simultáneamente licenciada bajo una licencia de Creative Commons que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

b. Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

c. Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (ver efecto del acceso abierto).