Commercial Tara Protein: Functional properties and use to stabilize sacha inchi oil emulsions obtained by ultrasound

DOI:

https://doi.org/10.17268/sci.agropecu.2024.031Keywords:

Caesalpinia spinosa, Plukenetia volubilis L., stability, droplet size, tara seed germ, tara proteinAbstract

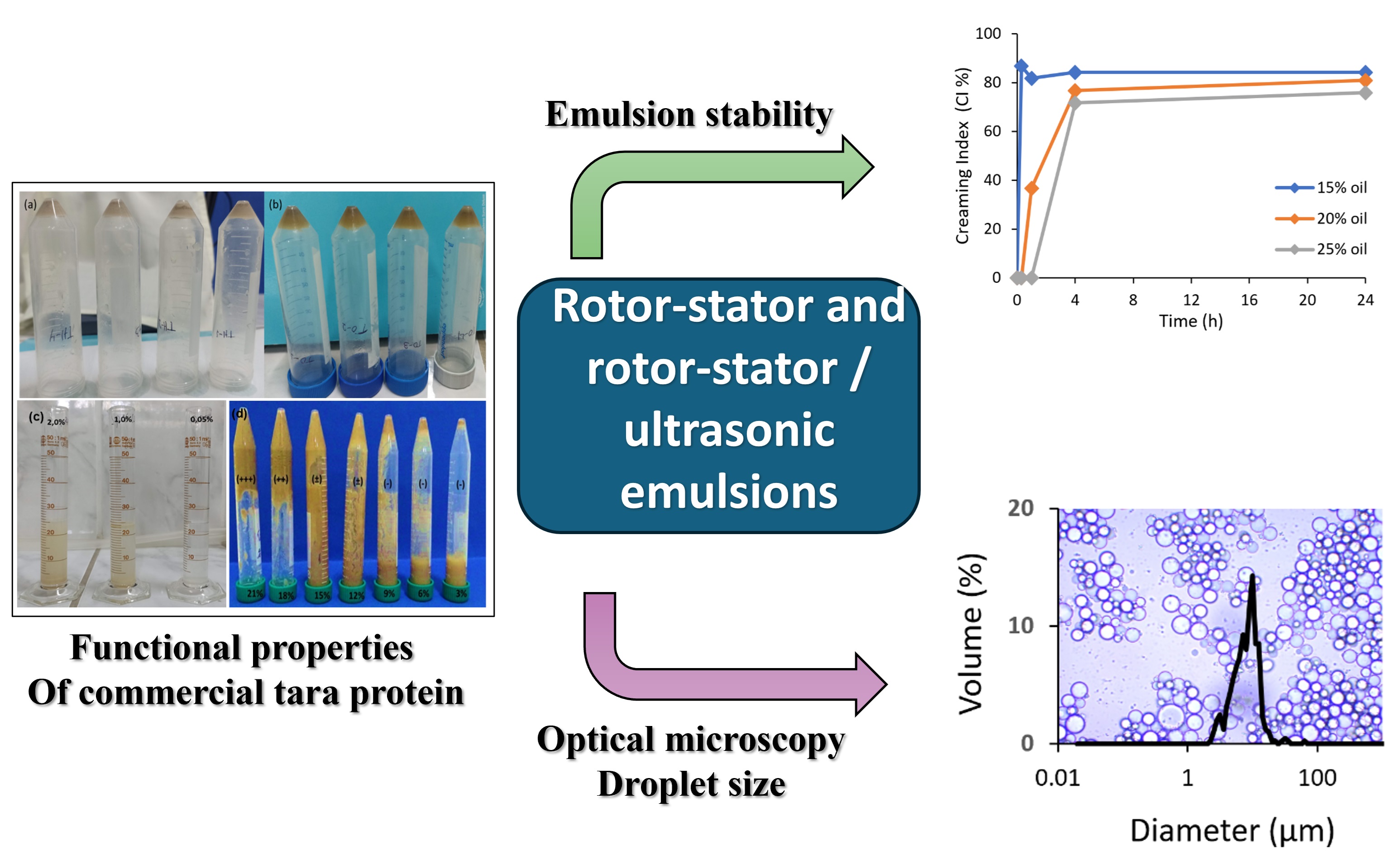

Commercial tara protein (CTP) and sacha inchi oil are promising Peruvian products for forming food emulsions. The present work aimed (1) to characterize the functional properties of CTP as a new protein source (water and oil absorption, foam, and gelling capacity) and (2) to deepen the CTP to form sacha inchi oil emulsions. The CTP (2%, 4%, 6%) and oil concentration (15%, 20% and 25%) were evaluated for rotor-stator (RS) emulsion production. Final emulsions (RS-US) were produced with RS emulsions added with 2% tara gum and ultrasound homogenization at 75% power amplitude for 3 min. Emulsions were analyzed according to gravitational stability, droplet size, and optical microscopy. The results showed that the CTP presented a centesimal composition of 6.03% moisture, 45.16% proteins, 12.32% lipids, 2.49% fiber, 6.04% ashes, and 27.96% carbohydrates. CTP had a greater oil absorption (2.1442 ±0.26 g/g solids) than water absorption (1.8201 ±0.02 g/g solids), did not present foam formation, and the least gelation concentration was 18%. RS-US emulsions prepared with 25% oil and 2% or 4% protein had greater stability against the creaming index and phase separation during 4h, despite emulsion prepared with 15% oil presenting the lowest mean droplet size. In conclusion, the results show that commercial tara protein effectively prepared emulsions with a combined method (rotor-stator, ultrasound, and tara gum).

References

Ahmad, S., Ahmad, M., Manzoor, K., Purwar, R., & Ikram, S. (2019). A review on latest innovations in natural gums based hydrogels: Preparations & applications. International Journal of Biological Macromolecules, 136, 870–890. https://doi.org/10.1016/j.ijbiomac.2019.06.113

Alarcón, R., Gonzales, B., Sotelo, A., Gallardo, G., Pérez-Camino, M. C., & Chasquibol, N. (2020). Microencapsulation of Sacha Inchi (Plukenetia huayllabambana) Oil by Spray Drying with Camu Camu (Myrciaria dubia (H.B.K.) Mc Vaugh) and Mango (Mangifera indica) Skins. Proceedings, 53(1), 11. https://doi.org/10.3390/proceedings2020053011

Alcântara, M. A., Lima, A. E. A. de, Braga, A. L. M., Tonon, R. V., Galdeano, M. C., Mattos, M. da C., Brígida, A. I. S., Rosenhaim, R., Santos, N. A. dos, & Cordeiro, A. M. T. de M. (2019). Influence of the emulsion homogenization method on the stability of chia oil microencapsulated by spray drying. Powder Technology, 354, 877–885. https://doi.org/10.1016/j.powtec.2019.06.026

AOAC. (2006). Official Methodos of Analisis (Association of Official Analytical Chemist (ed.); Vol 18). Association of Official Analytical Chemist.

Augustin, M. A., Sanguansri, L., & Bode, O. (2006). Maillard Reaction Products as Encapsulants for Fish Oil Powders. Journal of Food Science, 71(2), E25–E32. https://doi.org/10.1111/j.1365-2621.2006.tb08893.x

Boye, J. I., Aksay, S., Roufik, S., Ribéreau, S., Mondor, M., Farnworth, E., & Rajamohamed, S. H. (2010). Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Research International, 43(2), 537–546. https://doi.org/10.1016/j.foodres.2009.07.021

Chang, C., & Nickerson, M. T. (2018). Encapsulation of omega 3-6-9 fatty acids-rich oils using protein-based emulsions with spray drying. Journal of Food Science and Technology, 55(8), 2850–2861. https://doi.org/10.1007/s13197-018-3257-0

Cho, Y. H., & McClements, D. J. (2009). Theoretical stability maps for guiding preparation of emulsions stabilized by protein-polysaccharide interfacial complexes. Langmuir, 25(12), 6649–6657. https://doi.org/10.1021/la8006684

Choudhury, N., Meghwal, M., & Das, K. (2021). Microencapsulation: An overview on concepts, methods, properties and applications in foods. Food Frontiers, May, 1–17. https://doi.org/10.1002/fft2.94

Dakhili, S., Abdolalizadeh, L., Hosseini, S. M., Shojaee-Aliabadi, S., & Mirmoghtadaie, L. (2019). Quinoa protein: Composition, structure and functional properties. Food Chemistry, 299, 125161. https://doi.org/10.1016/j.foodchem.2019.125161

Dakia, P. A., Wathelet, B., & Paquot, M. (2007). Isolation and chemical evaluation of carob (Ceratonia siliqua L.) seed germ. Food Chemistry, 102, 1368–1374. https://doi.org/10.1016/j.foodchem.2006.05.059

Damodaran, S. (1996). Amino Acids, Peptides, and Proteins. In Food Chemistry (3rd ed, pp. 1–370). MARCEL DEKKER, INC.

De La Torre, L. (2018). La Tara beneficios ambientales y recomendaciones para su manejo sostenible en relictos de bosque y sistemas agroforestales. In Condesan. https://condesan.org/wp-content/uploads/2018/10/Libro-Tara-Condesan-2.pdf

Del Re-Jimenez, B. L., & Amado, R. (1989). Comparative study of the chemical composition of germ meals from carob, guar and tara seeds. Food Hydrocolloids, 3(2), 149–156. https://doi.org/10.1016/S0268-005X(89)80024-4

Fanali, C., Dugo, L., Cacciola, F., Beccaria, M., Grasso, S., Dachà, M., Dugo, P., & Mondello, L. (2011). Chemical characterization of Sacha inchi (Plukenetia volubilis L.) oil. Journal of Agricultural and Food Chemistry, 59(24), 13043–13049. https://doi.org/10.1021/jf203184y

Fierro, O., Siano, F., Bianco, M., Vasca, E., & Picariello, G. (2024). Comprehensive molecular level characterization of protein-and polyphenol-rich tara (Caesalpinia spinosa) seed germ flour suggests novel hypothesis about possible accidental hazards. Food Research International, 181, 114119. https://doi.org/10.1016/j.foodres.2024.114119

García, O., Aiello, C., Peña, M. C., Ruíz, J. L., & Acevedo, I. D. C. (2012). Caracterización físico quimicas y propiedades funcionales de la harina obtenida de granos de quinchoncho (Cajanus cajan (L.) Millsp.) sometidos a diferentes procesamientos. Revista Cientifica UDO Agrícola, 12(4), 919–928.

Gomes, M. H. G., & Kurozawa, L. E. (2020). Improvement of the functional and antioxidant properties of rice protein by enzymatic hydrolysis for the microencapsulation of linseed oil. Journal of Food Engineering, 267(June 2019), 109761. https://doi.org/10.1016/j.jfoodeng.2019.109761

Goyal, A., Tanwar, B., Kumar Sihag, M., & Sharma, V. (2022). Sacha inchi (Plukenetia volubilis L.): An emerging source of nutrients, omega-3 fatty acid and phytochemicals. Food Chemistry, 373(PB), 131459. https://doi.org/10.1016/j.foodchem.2021.131459

Ingrassia, R., Bea, L. L., Hidalgo, M. E., & Risso, P. H. (2019). Microstructural and textural characteristics of soy protein isolate and tara gum cold-set gels. LWT - Food Science and Technology, 113, 108286. https://doi.org/10.1016/j.lwt.2019.108286

Lafarga, T., Álvarez, C., Bobo, G., & Aguiló-Aguayo, I. (2018). Characterization of functional properties of proteins from Ganxet beans (Phaseolus vulgaris L. var. Ganxet) isolated using an ultrasound-assisted methodology. LWT - Food Science and Technology, 98, 106–112 Contents. https://doi.org/10.1016/j.lwt.2018.08.033

Lam, A. C. Y., Warkentin, T. D., Tyler, R. T., & Nickerson, M. T. (2017). Physicochemical and functional properties of protein isolates obtained from several pea cultivars. Cereal Chemistry, 94(1), 89–97. https://doi.org/10.1094/CCHEM-04-16-0097-FI

Liu, F., Chang, W., Chen, M., Xu, F., Ma, J., & Zhong, F. (2020). Film-forming properties of guar gum, tara gum and locust bean gum. Food Hydrocolloids, 98, 105007. https://doi.org/10.1016/J.FOODHYD.2019.03.028

Nesterenko, A., Alric, I., & Durrieu, V. (2013). Vegetable proteins in microencapsulation: A review of recent interventions and their effectiveness. Industrial Crops and Products, 42, 469–479. https://doi.org/10.1016/j.indcrop.2012.06.035

Otálora, M. C., Camelo, R., Wilches-Torres, A., Cárdenas-Chaparro, A., & Gómez Castaño, J. A. (2020). Encapsulation Effect on the In Vitro Bioaccessibility of Sacha Inchi Oil (Plukenetia volubilis L.) by Soft Capsules Composed of Gelatin and Cactus Mucilage Biopolymers. Polymers, 12(9), 1995. https://doi.org/10.3390/polym12091995

Pino, M. Y., Mandujano, N. C., Yépez, A. M., & Abram, A. P. De. (2013). Comparación De Tres Métodos Para Determinar El Porcentaje De Taninos Con El Método De La Norma Astm D6401 Aplicado Para La “Tara”, “Quinual”, “Mimosa” Y “Pino.” Revista de La Sociedad Química Del Perú, 79(4), 381–387.

Rodea-González, D. A., Cruz-Olivares, J., Román-Guerrero, A., Rodríguez-Huezo, M. E., Vernon-Carter, E. J., & Pérez-Alonso, C. (2012). Spray-dried encapsulation of chia essential oil (Salvia hispanica L.) in whey protein concentrate-polysaccharide matrices. Journal of Food Engineering, 111(1), 102–109. https://doi.org/10.1016/j.jfoodeng.2012.01.020

Santana, G. S., Oliveira Filho, J. G. de, & Egea, M. B. (2017). Características tecnológicas de farinhas vegetais comerciais. Revista De Agricultura Neotropical, 4(2), 88–95. https://doi.org/10.32404/rean.v4i2.1549

Santos Teixeira, C. (2009). Farinha da semente se jaca: caracterização físico-química e propriedades funcionais. Universidade Estadual do Sudoeste da Bahia.

Saout, C., Quéré, C., Donval, A., Paulet, Y. M., & Samain, J. F. (1999). An experimental study of the combined effects of temperature and photoperiod on reproductive physiology of Pecten maximus from the bay of brest (France). Aquaculture, 172(3–4), 301–314. https://doi.org/10.1016/S0044-8486(98)00406-2

Shao, Y., & Tang, C. H. (2014). Characteristics and oxidative stability of soy protein-stabilized oil-in-water emulsions: Influence of ionic strength and heat pretreatment. Food Hydrocolloids, 37, 149–158. https://doi.org/10.1016/j.foodhyd.2013.10.030

Silva, K. F. C. e., da Silva Carvalho, A. G., Rabelo, R. S., & Hubinger, M. D. (2019). Sacha inchi oil encapsulation: Emulsion and alginate beads characterization. Food and Bioproducts Processing, 116, 118–129. https://doi.org/10.1016/j.fbp.2019.05.001

Silva, S., Crisóstomo, O., Alvarez, E., Mendoza, G., Rondán, La., & Rubio, J. (2015). Evaluación de propiedades provee la harina de pajuro (Erythrina edulis) a las redes estructurales de Muffins. Revista de Ciencia, Tecnología y Desarrollo, 1(1), 77–88. http://revistascientificas.upeu.edu.pe/index.php/ri_ctd/article/view/360/368

Stone, A. K., Avarmenko, N. A., Warkentin, T. D., & Nickerson, M. T. (2015). Functional properties of protein isolates from different pea cultivars. Food Science and Biotechnology, 24(3), 827–833. https://doi.org/10.1007/s10068-015-0107-y

Stone, A. K., Nosworthy, M. G., Chiremba, C., House, J. D., & Nickerson, M. T. (2019). A comparative study of the functionality and protein quality of a variety of legume and cereal flours. Cereal Chemistry, 96(6), 1159–1169. https://doi.org/10.1002/cche.10226

Sun, L. H., Lv, S. W., Chen, C. H., & Wang, C. (2019). Preparation and characterization of rice bran protein-stabilized emulsion by using ultrasound homogenization. Cereal Chemistry, 96(3), 478–486. https://doi.org/10.1002/cche.10147

Taha, A., Hu, T., Zhang, Z., Bakry, A. M., Khalifa, I., Pan, S., & Hu, H. (2018). Effect of different oils and ultrasound emulsification conditions on the physicochemical properties of emulsions stabilized by soy protein isolate. Ultrasonics Sonochemistry, 49, 283–293. https://doi.org/10.1016/J.ULTSONCH.2018.08.020

Vélez-Erazo, E. M., Bosqui, K., Rabelo, R. S., Kurozawa, L. E., & Hubinger, M. D. (2020). High internal phase emulsions (HIPE) using pea protein and different polysaccharides as stabilizers. Food Hydrocolloids, 105, 105775. https://doi.org/10.1016/j.foodhyd.2020.105775

Vélez-Erazo, E. M., Consoli, L., & Hubinger, M. D. (2018). Mono and double-layer emulsions of chia oil produced with ultrasound mediation. Food and Bioproducts Processing, 112, 108–118. https://doi.org/10.1016/j.fbp.2018.09.007

Vicente, J., Pereira, L. J. B., Bastos, L. P. H., de Carvalho, M. G., & Garcia-Rojas, E. E. (2018). Effect of xanthan gum or pectin addition on Sacha Inchi oil-in-water emulsions stabilized by ovalbumin or tween 80: Droplet size distribution, rheological behavior and stability. International Journal of Biological Macromolecules, 120, 339–345. https://doi.org/10.1016/j.ijbiomac.2018.08.041

Vidaurre-Ruiz, J., Matheus-Diaz, S., Salas-Valerio, F., Barraza-Jauregui, G., Schoenlechner, R., & Repo-Carrasco-Valencia, R. (2019). Influence of tara gum and xanthan gum on rheological and textural properties of starch-based gluten-free dough and bread. European Food Research and Technology, 245(7), 1347–1355. https://doi.org/10.1007/s00217-019-03253-9

Zhang, J., Wang, G., Liang, Q., Cai, W., & Zhang, Q. (2019). Rheological and microstructural properties of gelatin B/tara gum hydrogels: Effect of protein/polysaccharide ratio, pH and salt addition. LWT, 103, 108–115. https://doi.org/10.1016/J.LWT.2018.12.080

Zhou, L., Zhang, J., Xing, L., & Zhang, W. (2021). Applications and effects of ultrasound assisted emulsification in the production of food emulsions: A review. Trends in Food Science and Technology, 110(1), 493–512. https://doi.org/10.1016/j.tifs.2021.02.008

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Scientia Agropecuaria

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

The authors who publish in this journal accept the following conditions:

a. The authors retain the copyright and assign to the magazine the right of the first publication, with the work registered with the Creative Commons attribution license, which allows third parties to use the published information whenever they mention the authorship of the work and the First publication in this journal.

b. Authors may make other independent and additional contractual arrangements for non-exclusive distribution of the version of the article published in this journal (eg, include it in an institutional repository or publish it in a book) as long as it clearly indicates that the work Was first published in this journal.

c. Authors are encouraged to publish their work on the Internet (for example, on institutional or personal pages) before and during the review and publication process, as it can lead to productive exchanges and a greater and faster dissemination of work Published (see The Effect of Open Access).