Xylanase production by Penicillium sp. Pn004 and its application for grass hydrolysis: High value subproduct from non-centrifugal sugarcane bagasse and wheat bran

DOI:

https://doi.org/10.17268/sci.agropecu.2024.015Palavras-chave:

Enzyme production, agro-industrial waste, enzymatic hydrolysis, ultrafiltration process, PenicilliumResumo

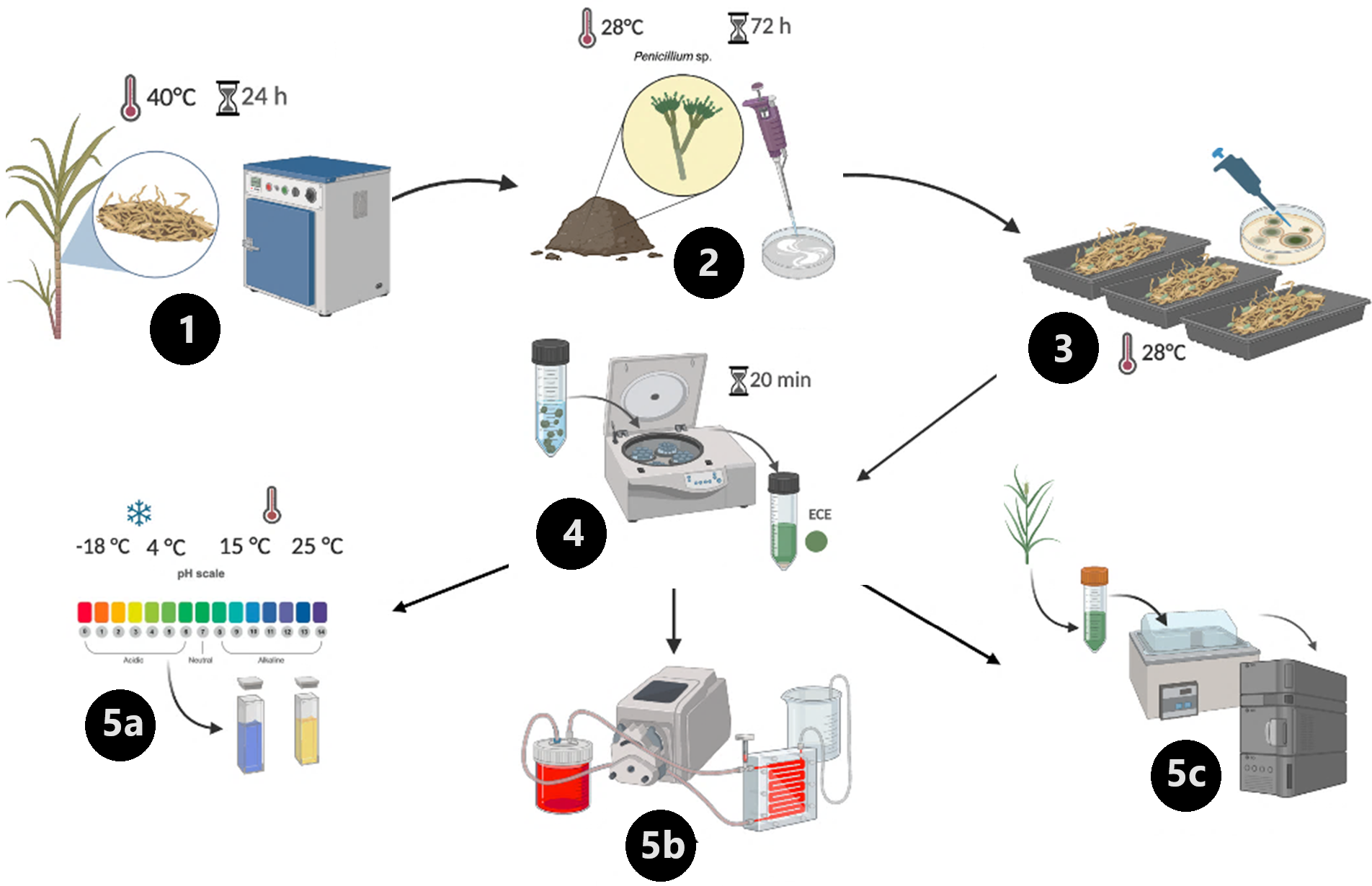

Worldwide more than 7 billion tons of lignocellulosic biomass will be produced by 2025. In Colombia, these residues are mainly disposed of in rivers and open fields, and only 10% is reused and recycled. Non-centrifugal sugarcane bagasse (SCB) is a residue obtained after sugarcane juice extraction during the manufacturing process of panela and is mostly used as fuel for boilers at sugar mills. Wheat bran (WB) is the main waste from wheat flour production. Nonetheless, the chemical composition of these by-products makes them suitable for use as substrates for hemicellulolytic enzyme production from fungi. Here, a whole process for production in a solid-state fermentation system, recovery, and ultrafiltration process for concentration of xylanases by Penicillium sp. Pn004 is presented. The higher productivity (26.7 ± 1.59 U gds-1 day-1) was reached on the fifth day of fermentation with an enzyme activity of 130.0 ± 7.95 U gds-1. The batch ultrafiltration process allowed increasing the xylanase activity up to 19-fold in the retentate, from 66.47 U mL-1 to 1486.83 U mL-1, without reaching a steady state flux through the membrane. Finally, the enzymatic extract achieved a 43% release of sugar from kikuyu grass (Cenchrus clandestinus), showing its potential to be used as an additive for silage or for enzymatic saccharification of lignocellulosic materials for sugar production.

Referências

Adhyaru, D. N., Bhatt, N. S., & Modi, H. A. (2015). Optimization of upstream and downstream process parameters for cellulase-poor-thermo-solvent-stable xylanase production and extraction by Aspergillus tubingensis FDHN1. Bioresources and Bioprocessing, 2(1), 1-14. https://doi.org/10.1186/S40643-014-0029-1

Adhyaru, D. N., Bhatt, N. S., Modi, H. A., & Divecha, J. (2016). Insight on xylanase from Aspergillus tubingensis FDHN1: Production, high yielding recovery optimization through statistical approach and application. Biocatalysis and Agricultural Biotechnology, 6, 51-57. https://doi.org/10.1016/J.BCAB.2016.01.014

Alves, T. P., Triques, C. C., da Silva, E. A., Fagundes‐Klen, M. R., & Hasan, S. D. M. (2022). Multi‐enzymatic recovery of fungal cellulases (Aspergillus niger) through solid‐state fermentation of sugarcane bagasse. The Canadian Journal of Chemical Engineering, 100(8), 1930-1940.

Andrea, J. B. S., Nelly, O. D. B., & José, E. Z. M. (2016). Efecto de Temperatura, pH, Concentración de Sustrato y Tipo de Enzima en la Hidrólisis Enzimática de VÍsceras de Tilapia Roja (Oreochromis spp.). Informacion Tecnologica. https://doi.org/10.4067/S0718-07642016000600007

Bailey, M. J., Biely, P., & Poutanen, K. (1992). Interlaboratory testing of methods for assay of xylanase activity. Journal of Biotechnology, 23(3), 257-270. https://doi.org/10.1016/0168-1656(92)90074-J

Bakari, H., Djomdi, Z. F., Roger, D. D., Cedric, D., Guillaume, P., et al. (2023). Sorghum (Sorghum bicolor L. Moench) and Its Main Parts (By-Products) as Promising Sustainable Sources of Value-Added Ingredients. Waste and Biomass Valorization, 14(4), 1023-1044.

Barciela, P., Perez-Vazquez, A., Fraga-Corral, M., & Prieto, M. A. (2023). Utility Aspects of Sugarcane Bagasse as a Feedstock for Bioethanol Production: Leading Role of Steam Explosion as a Pretreatment Technique. Processes, 11(11), 3116.

Berninger, T., González López, Ó., Bejarano, A., Preininger, C., & Sessitsch, A. (2018). Maintenance and assessment of cell viability in formulation of non-sporulating bacterial inoculants. Microbial Biotechnology, 11(2), 277-301. https://doi.org/10.1111/1751-7915.12880

Blasi, A., Verardi, A., Lopresto, C. G., Siciliano, S., & Sangiorgio, P. (2023). Lignocellulosic agricultural waste valorization to obtain valuable products: An overview. Recycling, 8(4), 61.

Bradford, M. . (1976). A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the principle of protein-dye bind- ing. Analytical Biochemistry, 72, 248-254.

Camassola, M., & Dillon, A. J. P. (2010). Cellulases and Xylanases Production by Penicillium echinulatum Grown on Sugar Cane Bagasse in Solid-State Fermentation. Applied Biochemistry and Biotechnology, 162(7), 1889-1900. https://doi.org/10.1007/S12010-010-8967-3

Chapman, R., & Stenzel, M. H. (2019). All Wrapped up: Stabilization of Enzymes within Single Enzyme Nanoparticles. https://doi.org/10.1021/jacs.8b10338

Chen, Z., Mense, A. L., Brewer, L. R., & Shi, Y.-C. (2023). Wheat bran layers: composition, structure, fractionation, and potential uses in foods. Critical Reviews in Food Science and Nutrition, 1-24.

Chilakamarry, C. R., Mimi Sakinah, A. M., Zularisam, A. W., Sirohi, R., Khilji, I. A., Ahmad, N., & Pandey, A. (2022). Advances in solid-state fermentation for bioconversion of agricultural wastes to value-added products: Opportunities and challenges. Bioresource Technology, 343, 126065. https://doi.org/10.1016/j.biortech.2021.126065

Cuadrado-Osorio, P. D., Ramírez-Mejía, J. M., Mejía-Avellaneda, L. F., Mesa, L., & Bautista, E. J. (2022). Agro-industrial residues for microbial bioproducts: A key booster for bioeconomy. Bioresource Technology Reports, 20, 101232. https://doi.org/10.1016/J.BITEB.2022.101232

da Silva, F. L., Magalhães, E. R. B., de Sá Leitão, A. L. O., & dos Santos, E. S. (2020). Production of lignocellulolytic enzymatic complex using pretreated carnauba straw as carbon source and application on sugarcane bagasse hydrolysis. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00815-w

Dahiya, S., Rapoport, A., & Singh, B. (2024). Biotechnological Potential of Lignocellulosic Biomass as Substrates for Fungal Xylanases and Its Bioconversion into Useful Products: A Review. Fermentation, 10(2), 82.

de Almeida Antunes Ferraz, J. L., Oliveira Souza, L., Gustavo de Araújo Fernandes, A., Luiz Ferreira Oliveira, M., de Oliveira, J. R., & Franco, M. (2019). Optimization of the solid-state fermentation conditions and characterization of xylanase produced by Penicillium roqueforti ATCC 10110 using yellow mombin residue (Spondias mombin L.). Chemical Engineering Communications, 207(1), 31-42. https://doi.org/10.1080/00986445.2019.1572000

de Oliveira Rodrigues, P., Gurgel, L. V. A., Pasquini, D., Badotti, F., Góes-Neto, A., & Baffi, M. A. (2020). Lignocellulose-degrading enzymes production by solid-state fermentation through fungal consortium among Ascomycetes and Basidiomycetes. Renewable Energy, 145, 2683-2693. https://doi.org/10.1016/j.renene.2019.08.041

DuBois, M., Gilles, K. A., Hamilton, J. K., Rebers, P. A. t, & Smith, F. (1956). Colorimetric method for determination of sugars and related substances. Analytical Chemistry, 28(3), 350-356.

Dutra, V. R., Silva, L. F., Oliveira, A. N. M., Beirigo, E. F., Arthur, V. M., et al. (2020). Fatal Case of Fungemia by Wickerhamomyces anomalus in a Pediatric Patient Diagnosed in a Teaching Hospital from Brazil. Journal of Fungi, 6(3), 147. https://doi.org/10.3390/JOF6030147

Eun, H.-M. (1996). 1 - Enzymes and Nucleic Acids: General Principles. Enzymology Primer for Recombinant DNA Technology, 1-108. https://doi.org/10.1016/B978-012243740-3/50004-1

Franco, D. G., de Almeida, A. P., Galeano, R. M. S., Vargas, I. P., Masui, D. C., et al. (2024). Exploring the potential of a new thermotolerant xylanase from Rasamsonia composticola (XylRc): production using agro-residues, biochemical studies, and application to sugarcane bagasse saccharification. 3 Biotech, 14(1), 3.

Ghoshal, G., Banerjee, U. C., & Shivhare, U. S. (2016). Utilization of agrowaste and xylanase production in solid state fermentation. Journal of Biochemical Technology, 6(3), 1013-1024.

Guo, G., Liu, Z., Xu, J., Liu, J., Dai, X., et al. (2012). Purification and characterization of a xylanase from Bacillus subtilis isolated from the degumming line. Journal of Basic Microbiology, 52(4), 419-428.

Gupta, P. K., Choudhary, S., Chandrananthi, C., Sharon Eveline, J., Sushmitha, S. P., et al. (2019). Fungal Biodiversity Producing Xylanase Enzymes Involved in Efficient Uses of Xylanolysis. Mycodegradation of Lignocelluloses, 51-63.

Heidary Vinche, M., Khanahmadi, M., Ataei, S. A., & Danafar, F. (2021). Optimization of process variables for production of beta-glucanase by Aspergillus niger CCUG33991 in solid-state fermentation using wheat bran. Waste and Biomass Valorization, 12, 3233-3243.

Inc, P. T. (2015). Collaborative data science. Montreal, QC: Plotly Technologies Inc. https://plot.ly

Ismail, S. A., Nour, S. A., & Hassan, A. A. (2022). Valorization of corn cobs for xylanase production by Aspergillus flavus AW1 and its application in the production of antioxidant oligosaccharides and removal of food stain. Biocatalysis and Agricultural Biotechnology, 41, 102311. https://doi.org/10.1016/J.BCAB.2022.102311

Jonathan, J., Tania, V., Tanjaya, J. C., & Katherine, K. (2021). Recent Advancements of Fungal Xylanase Upstream Production and Downstream Processing. Indonesian Journal of Life Sciences, 3(1), 37-58.

Kataria, R., & Ghosh, S. (2011). Saccharification of Kans grass using enzyme mixture from Trichoderma reesei for bioethanol production. Bioresource Technology, 102(21), 9970-9975.

Katileviciute, A., Plakys, G., Budreviciute, A., Onder, K., Damiati, S., & Kodzius, R. (2019). A sight to wheat bran: High value-added products. Biomolecules, 9(12), 887.

Knob, A., Beitel, S. M., Fortkamp, D., Terrasan, C. R. F., & Almeida, A. F. De. (2013). Production, purification, and characterization of a major Penicillium glabrum xylanase using Brewer’s spent grain as substrate. BioMed Research International, 2013. https://doi.org/10.1155/2013/728735

Knob, A., & Carmona, E. C. (2010). Purification and characterization of two extracellular xylanases from Penicillium sclerotiorum: a novel acidophilic xylanase. Applied Biochemistry and Biotechnology, 162, 429-443.

Kuddus, M., & Ramteke, P. W. (2023). Value-Addition in Agri-Food Industry Waste Through Enzyme Technology. Elsevier.

Kumar, A., Verma, V., Dubey, V. K., Srivastava, A., Garg, S. K., Singh, V. P., & Arora, P. K. (2023). Industrial applications of fungal lipases: A review. Frontiers in Microbiology, 14. https://doi.org/10.3389/fmicb.2023.1142536

Lafond, M., Tauzin, A., Desseaux, V., Bonnin, E., Ajandouz, E. H., & Giardina, T. (2011). GH10 xylanase D from Penicillium funiculosum: Biochemical studies and xylooligosaccharide production. Microbial Cell Factories, 10(1), 1-8. https://doi.org/10.1186/1475-2859-10-20

Lee, H., Sohn, Y. J., Jeon, S., Yang, H., Son, J., Kim, Y. J., & Park, S. J. (2023). Sugarcane wastes as microbial feedstocks: A review of the biorefinery framework from resource recovery to production of value-added products. Bioresource Technology, 128879.

Liu, Z., Dai, X., Zhang, J., Xu, J., Duan, S., et al. (2011). Screening of a xylanase high-producing strain and its rapid separation and purification. Annals of Microbiology, 61(4), 901-906.

Lutz, H. (2015). Configurations. Ultrafiltration for Bioprocessing: Development and Implementation of Robust Processes, 77-94. https://doi.org/10.1016/B978-1-907568-46-6.00005-7

Magalhães, A. I., de Carvalho, J. C., de Melo Pereira, G. V., Karp, S. G., Câmara, M. C., Medina, J. D. C., & Soccol, C. R. (2019). Lignocellulosic biomass from agro-industrial residues in South America: current developments and perspectives. Biofuels, Bioproducts and Biorefining, 13(6), 1505-1519. https://doi.org/10.1002/bbb.2048

Marques, N. P., de Cassia Pereira, J., Gomes, E., da Silva, R., Araújo, A. R., et al. (2018). Cellulases and xylanases production by endophytic fungi by solid state fermentation using lignocellulosic substrates and enzymatic saccharification of pretreated sugarcane bagasse. Industrial Crops and Products, 122, 66-75. https://doi.org/10.1016/j.indcrop.2018.05.022

Martinez-Hernandez, E., Amezcua-Allieri, M. A., Sadhukhan, J., & Anell, J. A. (2018). Sugarcane bagasse valorization strategies for bioethanol and energy production. Sugarcane-Technology and Research.

Mejía-Avellaneda, L. F., Suárez, H., Jiménez, H., & Mesa, L. (2021). Challenges and opportunities for the production of lactic acid bacteria inoculants aimed for ensiling processes. Critical Reviews in Biotechnology, 42(7), 1028-1044. https://doi.org/10.1080/07388551.2021.1988508

Mendieta, O., Castro, L., Rodríguez, J., & Escalante, H. (2020). Management and valorization of waste from a non-centrifugal cane sugar mill via anaerobic co-digestion: Technical and economic potential. Bioresource Technology, 316, 123962. https://doi.org/10.1016/j.biortech.2020.123962

Menegol, D., Scholl, A. L., Fontana, R. C., Dillon, A. J. P., & Camassola, M. (2014). Potential of a Penicillium echinulatum enzymatic complex produced in either submerged or solid-state cultures for enzymatic hydrolysis of elephant grass. Fuel, 133, 232-240.

Miller, G. L. (1959). Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Analytical Chemistry, 31(3), 426-428. https://doi.org/10.1021/ac60147a030

Mishra, B., Mohanta, Y. K., Reddy, C. N., Reddy, S. D. M., Mandal, S. K., Yadavalli, R., & Sarma, H. (2023). Valorization of agro-industrial biowaste to biomaterials: An innovative circular bioeconomy approach. Circular Economy, 100050.

Moran-Aguilar, M. G., Costa-Trigo, I., Calderón-Santoyo, M., Domínguez, J. M., & Aguilar-Uscanga, M. G. (2021). Production of cellulases and xylanases in solid-state fermentation by different strains of Aspergillus niger using sugarcane bagasse and brewery spent grain. Biochemical Engineering Journal, 172, 108060.

Muck, R., Nadeau, E., McAllister, T., Contreras-Govea, F., Santos, M., & Kung Jr, L. (2018). Silage review: Recent advances and future uses of silage additives. Journal of Dairy Science, 101, 3980-4000. https://doi.org/10.3168/jds.2017-13839

Murthy, P., & Madahava, M. (2012). Production and Application of Xylanase from Penicillium sp . Food Bioprocess Technology, 5, 657-664. https://doi.org/10.1007/s11947-010-0331-7

Mustafa, G., Arshad, M., Bano, I., & Abbas, M. (2023). Biotechnological applications of sugarcane bagasse and sugar beet molasses. Biomass Conversion and Biorefinery, 13(2), 1489-1501.

Ning, Y.-N., Tian, D., Zhao, S., & Feng, J.-X. (2024). Regulation of genes encoding polysaccharide-degrading enzymes in Penicillium. Applied Microbiology and Biotechnology, 108(1), 1-12.

Paschoa, J. L. F., Ávila, P. F., Ramalho, E. X., Silva, M. F., Bueno, D., & Goldbeck, R. (2024). Production and purification of xylooligossaccharides from sugarcane bagasse and antioxidant potential assessment for functional ingredient application in the food industry. Industrial Crops and Products, 208, 117844.

Peñaranda, L. V., Montenegro, S. P., & Giraldo, P. A. (2018). Aprovechamiento de Residuos Agroindustriales en Colombia. Revista de Investigación Agraria y Ambiental, 8(2), 141-150.

Qadir, F., Shariq, M., Ahmed, A., & Sohail, M. (2018). Evaluation of a yeast co-culture for cellulase and xylanase production under solid state fermentation of sugarcane bagasse using multivariate approach. Industrial Crops and Products, 123, 407-415. https://doi.org/10.1016/j.indcrop.2018.07.021

Rosa, F. M., Mota, T. F. M., Busso, C., Arruda, P. V. de, Brito, P. E. M., et al. (2024). Filamentous Fungi as Bioremediation Agents of Industrial Effluents: A Systematic Review. Fermentation, 10(3), 143.

Saini, P., Sinha, A. S. K., & Prasad, K. (2023). Wet refining: A novel approach for modification of wheat bran fiber. Innovative Food Science & Emerging Technologies, 90, 103508.

Savou, V., Grause, G., Kumagai, S., Saito, Y., Kameda, T., & Yoshioka, T. (2019). Pyrolysis of sugarcane bagasse pretreated with sulfuric acid. Journal of the Energy Institute, 92(4), 1149-1157. https://doi.org/10.1016/j.joei.2018.06.003

Silva, T. A. L., Zamora, H. D. Z., Varão, L. H. R., Prado, N. S., Baffi, M. A., & Pasquini, D. (2018). Effect of Steam Explosion Pretreatment Catalysed by Organic Acid and Alkali on Chemical and Structural Properties and Enzymatic Hydrolysis of Sugarcane Bagasse. Waste and Biomass Valorization, 9(11), 2191-2201. https://doi.org/10.1007/s12649-017-9989-7

Sundaram, T., Govindarajan, R. K., Nagarajan, S., & Rajamani Sekar, S. K. (2024). Advancements in biosurfactant production using agro-industrial waste for industrial and environmental applications. Frontiers in Microbiology, 15, 1357302.

Valle-Pérez, A. U., Flores-Cosío, G., & Amaya-Delgado, L. (2021). Bioconversion of Agave Bagasse to Produce Cellulases and Xylanases by Penicillium citrinum and Aspergillus fumigatus in Solid-State Fermentation. Waste and Biomass Valorization, 12(11), 5885-5897. https://doi.org/10.1007/S12649-021-01397-Y

Vásquez, A. F. L., Rey, G. A. O., & Rodríguez, F. A. R. (2010). Obtaining of reducing sugars from kikuyu grass (Pennisetum clandestinum). AVANCES Investigación En Ingeniería, 1(13), 98-101.

Villanueva, R. A. M., & Chen, Z. J. (2019). ggplot2: elegant graphics for data analysis. Taylor & Francis.

Visentin, T. G., Guimarães, B. M., & Bastos, R. G. (2024). Effects of temperature, pH, and C/N ratio of sugarcane wastewater processing (vinasse) on Phormidium autumnale heterotrophic cultivation. Algal Research, 77, 103349.

Wagh, M. S., Sowjanya, S., Nath, P. C., Chakraborty, A., Amrit, R., et al. (2024). Valorisation of agro-industrial wastes: circular bioeconomy and biorefinery process-a sustainable symphony. Process Safety and Environmental Protection, 183, 708-725. https://doi.org/10.1016/j.psep.2024.01.055

Yilmaz, E., & Bagci, P. O. (2019). Ultrafiltration of Broccoli Juice Using Polyethersulfone Membrane: Fouling Analysis and Evaluation of the Juice Quality. Food and Bioprocess Technology, 12(8), 1273-1283. https://doi.org/10.1007/S11947-019-02292-0

Downloads

Publicado

Como Citar

Edição

Seção

Licença

Copyright (c) 2024 Scientia Agropecuaria

Este trabalho está licenciado sob uma licença Creative Commons Attribution-NonCommercial 4.0 International License.

Los autores que publican en esta revista aceptan los siguientes términos:

a. Los autores conservan los derechos de autor y conceden a la revista el derecho publicación, simultáneamente licenciada bajo una licencia de Creative Commons que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

b. Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

c. Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (ver efecto del acceso abierto).