Microwave assisted popping of five Andean cultivars of ñuña beans: Process optimization and effect of grain’s moisture content

DOI:

https://doi.org/10.17268/sci.agropecu.2024.027Palabras clave:

reventado, ñuna, reventado por microondas, granos de legumbres, snackResumen

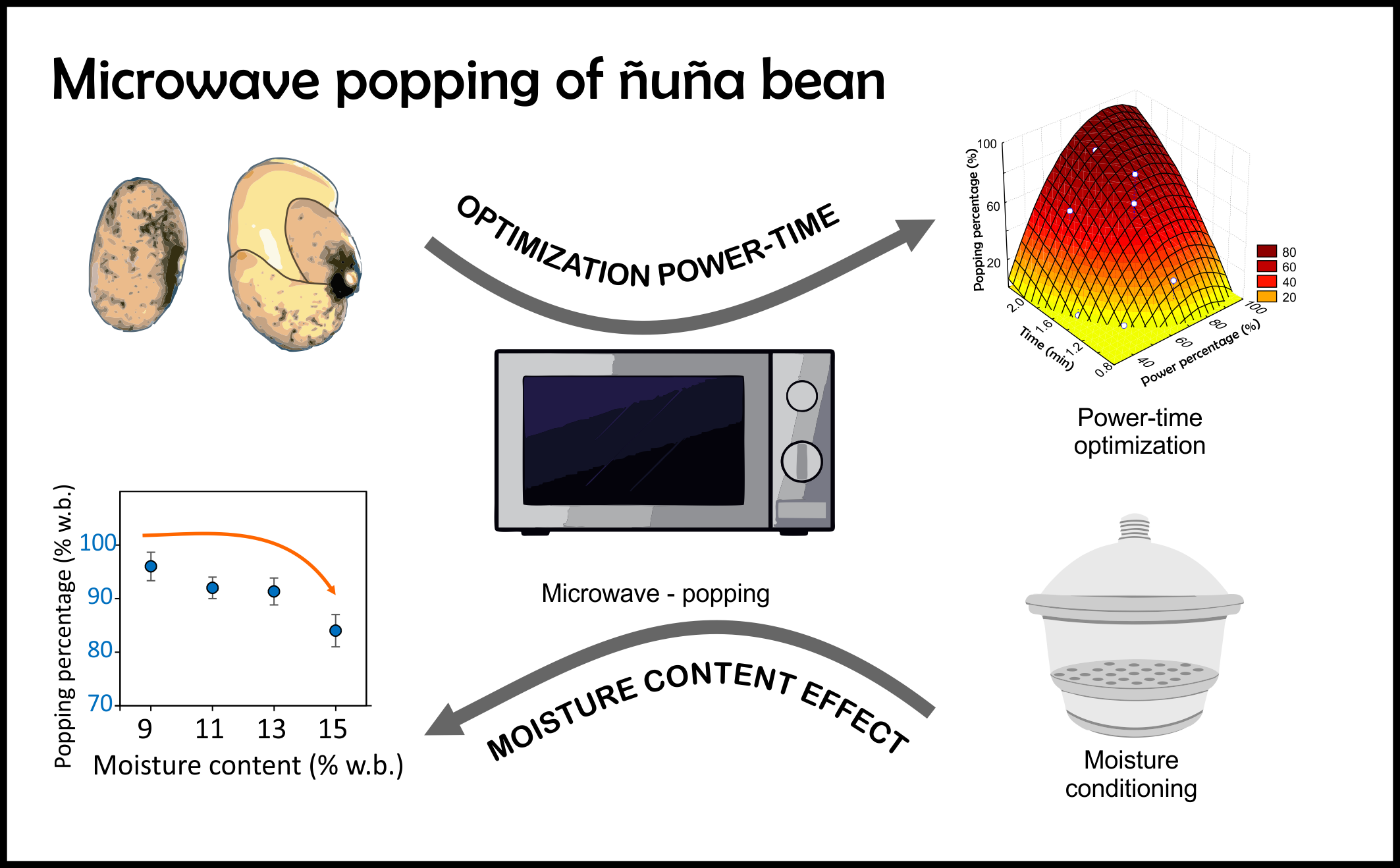

This research aimed to optimize the microwave popping process of 5 cultivars of ñuña beans under different moisture content. This work was divided into two stages: determining the optimal time and microwave power for maximum popping and studying the effect of initial grain moisture content on popping percentage. For this, grains were conditioned to 9%, 11%, 13% and 15% of moisture content. The results suggested that only the cultivars “Vaquita poroto”, “Negra” and “Jabona” cultivars reach the highest popping percentages selecting optimum microwave power and process time. In addition, this work found that for every studied cultivar, moisture content between 9 to 11% w.b (wet basis). is suitable to maximize popping percentage. Moisture contents greater than 13% w.b. drastically reduced the popping percentage but increased expansion percentage. In conclusion, this work recommended “Vaquita poroto” cultivar since it presented the maximum popping percentage even at moisture content up to 13% w.b. As practical applications, popping process using microwave has not been widely study, especially for non-conventional popping beans. These beans are consumed in South America; however, they can be exported as a healthy snack. In addition, this work optimized the process and selected the best cultivar of this bean to be industrialized. In addition, the present work demonstrated the importance of the initial moisture content of the beans to improve quality and yield of burst grains.

Citas

Anithasri, M., Vennila, P., & Ilamaran, M. (2018). Studies on Screening of Sorghum Varieties for Popping. Madras Agricultural Journal, 105. https://doi.org/10.29321/MAJ.2018.000138

Anne Allred-Coyle, R. B. T., Wendy Reiboldt, Mani Thakur, Tracey. (2000). Effects of moisture content, hybrid variety, kernel size, and microwave wattage on the expansion volume of microwave popcorn. International Journal of Food Sciences and Nutrition, 51(5), 389-394. https://doi.org/ 10.1080/096374800426984

Castro-Giráldez, M., Fito, P., Prieto, J., Andrés, A., & Fito, P. (2012). Study of the puffing process of amaranth seeds by dielectric spectroscopy. Journal of food engineering, 110(2), 298-304. https://doi.org/10.1016/j.jfoodeng.2011.04.012

Cruz Balarezo, J., Camarena Mayta, F., Baudoin, J. P., Huaringa Joaquín, A., & Blas Sevillano, R. (2009). Evaluación agromorfológica y caracterización molecular de la ñuña (Phaseolus vulgaris L.). Idesia (Arica), 27(1), 29-40. http://dx.doi.org/10.4067/S0718-34292009000100005

de la O-Olán, M., Santacruz-Varela, A., Sangerman-Jarquín, D. M., Gámez-Vázquez, A. J., Arellano-Vázquez, J. L., Valadez-Bustos, M. G., & Perches, M. A. A. (2018). Estandarización del método de reventado para la evaluación experimental del maíz palomero. Revista Mexicana de Ciencias Agrícolas, 9(7), 1471-1471. https://doi.org/10.29312/remexca.v9i7.1675

Devi, M. K., & Das, S. K. (2018). Microwave popping characteristics of paddy as affected by sample placement and geometry and process optimization. Journal of food engineering, 221, 45-53. https://doi.org/10.1016/j.jfoodeng.2017.09.026

Ernoult, V., Moraru, C., & Kokini, J. (2002). Influence of fat on expansion of glassy amylopectin extrudates by microwave heating. Cereal Chemistry, 79(2), 265-273. https://doi.org/10.1094/CCHEM.2002.79.2.265

ERTAŞ, N., Soylu, S., & Bilgicli, N. (2009). Effects of kernel properties and popping methods on popcorn quality of different corn cultivars. Journal of food process engineering, 32(4), 478-496. https://doi.org/10.1111/j.1745-4530.2007.00228.x

Gökmen, S. (2004). Effects of moisture content and popping method on popping characteristics of popcorn. Journal of Food Engineering, 65(3), 357-362. https://doi.org/10.1016/j.jfoodeng.2004.01.034

Hoseney, R., Zeleznak, K., & Abdelrahman, A. (1983). Mechanism of popcorn popping. Journal of cereal Science, 1(1), 43-52.

Kumari, R., Singh, K., Jha, S., Singh, R., Sarkar, S. K., & Bhatia, N. (2018). Nutritional composition and popping characteristics of some selected varieties of pearl millet (Pennisetum glaucum).

Llopart, E. E., & Drago, S. R. (2016). Physicochemical properties of sorghum and technological aptitude for popping. Nutritional changes after popping. LWT-Food Science and Technology, 71, 316-322. https://doi.org/10.1016/j.lwt.2016.04.006

Maisont, S., & Narkrugsa, W. (2010). Effects of salt, moisture content and microwave power on puffing qualities of puffed rice. Agriculture and Natural Resources, 44(2), 251-261.

Marrelli, M., Statti, G., & Conforti, F. (2020). A review of biologically active natural products from Mediterranean wild edible plants: Benefits in the treatment of obesity and its related disorders. Molecules, 25(3), 649. https://doi.org/10.3390/molecules25030649

Metzger, D., Hsu, K., Ziegler, K., & Bern, C. (1989). Effect of moisture content on popcorn popping volume for oil and hot-air popping. Cereal chemistry (USA).

Miano, A. C., & Augusto, P. E. D. (2015). From the sigmoidal to the downward concave shape behavior during the hydration of grains: Effect of the initial moisture content on Adzuki beans (Vigna angularis). Food and bioproducts processing, 96, 43-51. https://doi.org/http://dx.doi.org/10.1016/j.fbp.2015.06.007

Mir, S. A., Bosco, S. J. D., Shah, M. A., Mir, M. M., & Sunooj, K. V. (2016). Process optimization and characterization of popped Brown Rice. International Journal of Food Properties, 19(9), 2102-2112. https://doi.org/10.1080/10942912.2015.1105254

Mishra, G., Joshi, D., & Panda, B. K. (2014). Popping and puffing of cereal grains: a review. Journal of grain processing and storage, 1(2), 34-46.

Otálora, J. M., Ligarreto, G. A., & Romero, A. (2006). Comportamiento de fríjol común (Phaseolus vulgaris L.) tipo reventón por características agronómicas y de calidad de grano. Agronomía Colombiana, 24(1), 7-16.

Pastor, S., Fuentealba, B., & Ruiz, M. (2006). Cultivos subutilizados en el Perú: análisis de las políticas públicas relativas a su conservación y uso sostenible.

Pohndorf, R. S., Lang, G. H., Ferreira, C. D., Ziegler, V., Goebel, J. T., & de Oliveira, M. (2019). Kinetic evaluation and optimization of red popcorn grain drying: Influence of the temperature and air velocity on the expansion properties and β‐carotene content. Journal of Food Process Engineering, 42(6), e13204. https://doi.org/10.1111/jfpe.13204

Puangjinda, K., Matan, N., & Nisoa, M. (2016). Effects atmospheric radio-frequency plasma treatment on popping characteristics of popped rice and its nutritional evaluation. Innovative food science & emerging technologies, 35, 119-124. https://doi.org/10.1016/j.ifset.2016.04.010

Pugh, N., Awika, J. M., & Rooney, W. L. (2017). Heritability of popping characteristics in sorghum grain. Crop Science, 57(1), 71-77. https://doi.org/10.2135/cropsci2016.04.0250

Rezaey, M., Heitholt, J., Miles, C., & Ganjyal, G. M. (2024). Physicochemical characteristics and popping efficiencies of popping beans from different breeding programs and grow-out locations. Cereal chemistry, 101(1), 166-178. https://doi.org/https://doi.org/10.1002/cche.10733

Sanchez-Pardo, M. E., Ortiz-Moreno, A., García-Zaragoza, F., Necoechea-Mondragón, H., & Chanona-Perez, J. J. (2012). Comparison of pound cake baked in a two cycle microwave-toaster oven and in conventional oven. LWT-Food Science and Technology, 46(1), 356-362. https://doi.org/10.1016/j.lwt.2011.08.013

Shimoni, E., Dirks, E., & Labuza, T. (2002). The relation between final popped volume of popcorn and thermal–physical parameters. LWT-Food Science and Technology, 35(1), 93-98. https://doi.org/10.1006/fstl.2001.0823

Solanki, C., Mridula, D., & Nanda, K. (2018). Microwave vs conventional popping system: A comparative evaluation for maize popping. IJCS, 6(6), 176-181.

Spaeth, S. C., Debouck, D. G., Tohme, J., & Beem, J. v. (1989). Microstructure of nuñas: Andean popping beans (Phaseolus vulgaris L.). Food Structure, 8(2), 13.

Srdić, J., Milašinović-Šeremešić, M., Radosavljević, M., Kravić, N., & Babić, V. (2017). Evaluation of agronomic and sensory characteristics of the popcorn kernel. Journal on Processing and Energy in Agriculture, 21(4), 185-187. https://doi.org/10.5937/JPEA1704185S

Srdić, J., Pajić, Z., Filipović, M., & Sečanski, M. (2015). The influence of moisture content of grain on popping volume of popcorn hybrids (Zea mays l. everta). Journal on Processing and Energy in Agriculture, 19(1), 24-26.

Srdić, J., Perić, V., Kolarić, L., Kravić, N., Babić, V., & Simić, M. (2018). The influence of moisture content on popping traits in popcorn. Journal on Processing and Energy in Agriculture, 22(4), 184-187.

Stewart, F. C. (1923). Relation of moisture content and certain other factors to the popping of popcorn.

Swarnakar, A. K., Devi, M. K., & Das, S. (2014). Popping characteristics of paddy using microwave energy and optimization of process parameters. International Journal of Food Studies, 3(1). https://doi.org/10.7455/ijfs/3.1.2014.a4

Swarnakar, A. K., Mohapatra, M., & Das, S. K. (2022). A review on processes, mechanisms, and quality influencing parameters for puffing and popping of grains. Journal of Food Processing and Preservation, 46(10), e16891. https://doi.org/https://doi.org/10.1111/jfpp.16891

Swarnakar, A. K., Srivastav, P. P., & Das, S. K. (2020). Optimization of pressure parboiling conditions and pre-conditioned moisture content of brown rice (unpolished rice) for microwave puffing and its comparison with hot sand bed puffing. International Journal of Food Studies, 9. https://doi.org/10.7455/ijfs/9.SI.2020.a1

Valladolid Chiroque, A. R. (2016). Leguminosas de Grano: Cultivares y Clases Comerciales del Perú. Lima, Perú: Heinz Plenge Pardo

van Beem, J., & Spaeth, S. C. (1990). Popping in Nuña Beans (Phaseolus vulgaris, Fabaceae) Grown outside of Traditional Areas. Economic Botany, 133-135.

Van der Sman, R., & Bows, J. (2017). Critical factors in microwave expansion of starchy snacks. Journal of Food Engineering, 211, 69-84. https://doi.org/10.1016/j.jfoodeng.2017.05.001

Vázquez, C., Ortega, C., Guerrero, H., & Coutiño, E. (2011). Evaluación bioquímica e industrial de razas nativas de maíz de la región serrana de Sonora. Amplitud, mejoramiento, usos y riesgos de la diversidad genética de maíz en México. Sociedad Mexicana de Fitogenética, AC. Chapingo, Estado de México, 97-142.

Vorwald, J., & Nienhuis, J. (2009a). Effects of seed moisture content, cooking time, and chamber temperature on nuña bean (Phaseolus vulgaris L.) popping. HortScience, 44(1), 135-137. https://doi.org/10.21273/HORTSCI.44.1.135

Vorwald, J., & Nienhuis, J. (2009b). Heritability and correlations among popping characteristics and seed weight in a broad-based temperate-adapted nuña bean (Phaseolus Vulgaris L.) population. Hortscience, 44(1), 214-216. https://doi.org/10.21273/HORTSCI.44.1.214

Ziegler, K. E. (2000). Popcorn. In Specialty corns (pp. 211-246). CRC Press.

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2024 Scientia Agropecuaria

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial 4.0.

Los autores que publican en esta revista aceptan los siguientes términos:

a. Los autores conservan los derechos de autor y conceden a la revista el derecho publicación, simultáneamente licenciada bajo una licencia de Creative Commons que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

b. Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

c. Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (ver efecto del acceso abierto).