Biomass briquettes: Raw material, technologies and densification parameters, quality and future challenges

DOI:

https://doi.org/10.17268/sci.agropecu.2025.024Palabras clave:

Biomass, briquettes, densification, binders, agricultural residues, solid biofuelsResumen

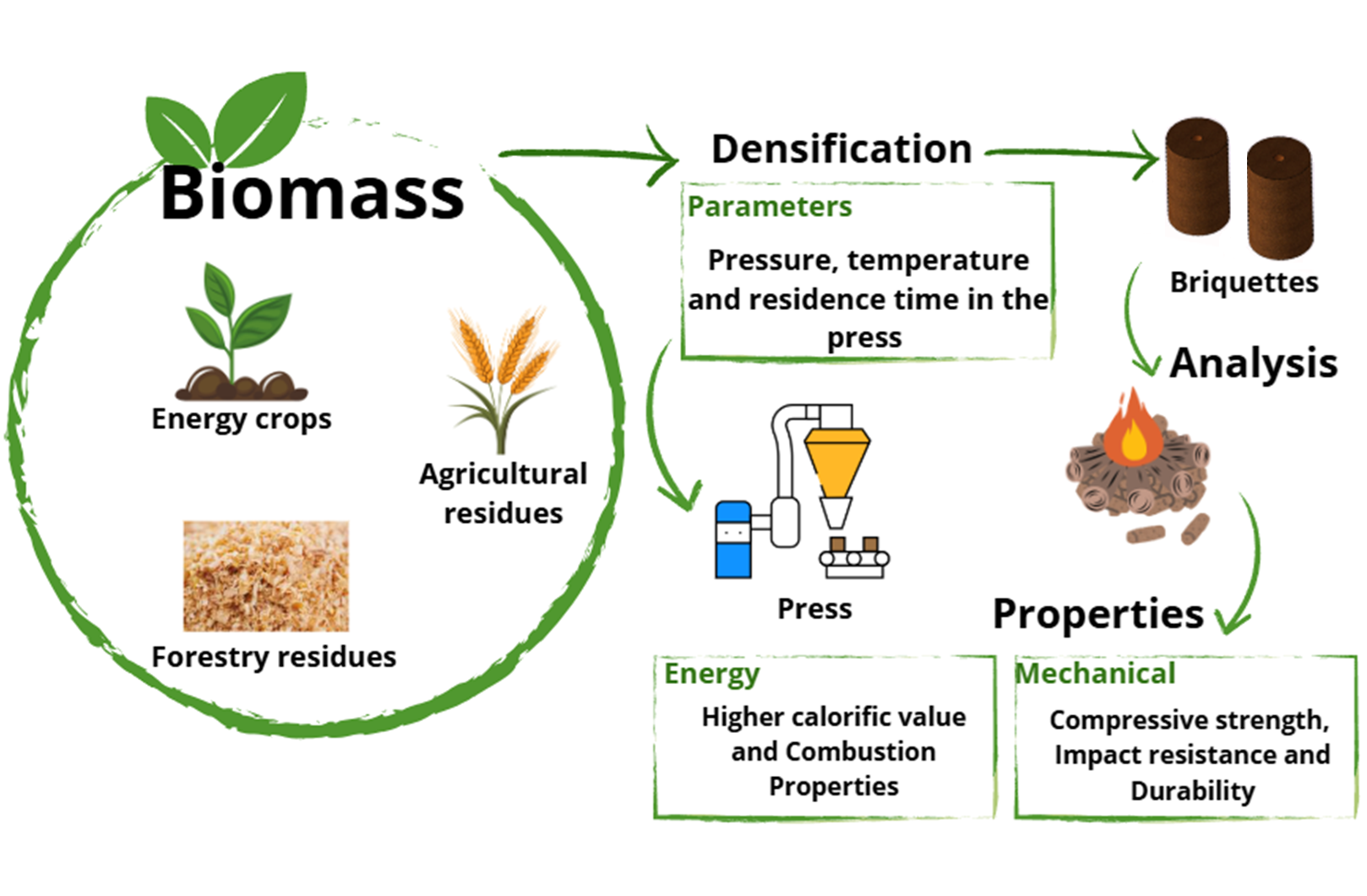

The implementation of renewable energy is a viable option to reduce the use of fossil fuels and polluting emissions. Biomass is an excellent renewable energy source and is cleaner than coal. It can be obtained from organic inputs such as wood and agricultural waste and, if used sustainably, can meet the energy needs of various sectors. Densification is a technology with the potential to convert lignocellulosic waste into clean and sustainable solid biofuels. Densification involves compacting loose biomass particles using a mechanical press to produce sustainable solid biofuels with low pollutant content that are not dependent on fossil fuels. The important parameters during the manufacturing process are pressure, temperature, residence time in the press and shape of the briquettes. The production of briquettes imparts certain important properties to the briquettes, such as mechanical strength, density, combustion time and calorific quality. These properties depend on the raw material, binder and pressing process and are of utmost importance during transportation, handling and combustion of briquettes. In accordance with the above, this paper analyzes and describes the properties of different agricultural residues used in the production of briquettes and their potential as a sustainable energy source, as well as the properties that must be evaluated to define the quality of the briquettes. One of the current and future challenges is to improve the processes for producing briquettes using residual biomass and, to the minimum extent possible, binders that favor their energy and mechanical properties.

Citas

Afra, E., Abyaz, A., & Saraeyan, A. (2021). The production of bagasse biofuel briquettes and the evaluation of natural binders (LNFC, NFC, and lignin) effects on their technical parameters. Journal of Cleaner Production, 278. https://doi.org/10.1016/j.jclepro.2020.123543

Antwi-Boasiako, C., & Acheampong, B. B. (2016). Strength properties and calorific values of sawdust-briquettes as wood-residue energy generation source from tropical hardwoods of different densities. Biomass and Bioenergy, 85, 144–152. https://doi.org/10.1016/J.BIOMBIOE.2015.12.006

Anukam, A., Berghel, J., Henrikson, G., Frodeson, S., & Ståhl, M. (2021). A review of the mechanism of bonding in densified biomass pellets. Renewable and Sustainable Energy Reviews, 148, 111249. https://doi.org/10.1016/J.RSER.2021.111249

ASTM D440-86 (2002). Test Method of Drop Shatter Test for Coal. https://doi.org/10.1520/D0440-86R02

ASTM D2166-85 (2008). Standard Test. Method of Compressive Strenght of Wood. In ASTM International: West Conshohocken.

ASTM D4442 (2016). Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. ASTM International, United States.

ASTM E711-23e1 (2023). Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter. ASTM International.

ASTM E872-82 (2006). Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. ASTM International, United States.

ASTM E1755-01 (2007). Standard Test Method for Ash in Biomass. ASTM International, United States.

Ayodeji Akogun, O., & Waheed, A. (2022). Development and performance evaluation of a piston type hydraulically operated briquetting machine with replaceable moulds. Agricultural Engineering International: CIGR Journal, 24(1), 113-127.

Baeyens, J., Kang, Q., Appels, L., Dewil, R., Lv, Y., & Tan, T. (2015). Challenges and opportunities in improving the production of bio-ethanol. Progress in Energy and Combustion Science, 47, 60–88. https://doi.org/10.1016/J.PECS.2014.10.003

Bajwa, D. S., Peterson, T., Sharma, N., Shojaeiarani, J., & Bajwa, S. G. (2018). A review of densified solid biomass for energy production. Renewable and Sustainable Energy Reviews, 96, 296–305. https://doi.org/10.1016/J.RSER.2018.07.040

Bhatt, S. M., & Bal, J. S. (2019). Bioprocessing Perspective in Biorefineries. 1–23. https://doi.org/10.1007/978-3-319-94797-6_1

Bot, B. V., Sosso, O. T., Tamba, J. G., Lekane, E., Bikai, J., & Ndame, M. K. (2023). Preparation and characterization of biomass briquettes made from banana peels, sugarcane bagasse, coconut shells and rattan waste. Biomass Conversion and Biorefinery, 13(9), 7937–7946. https://doi.org/10.1007/s13399-021-01762-w

Bot, B. V., Axaopoulos, P. J., Sosso, O. T., Sakellariou, E. I., & Tamba, J. G. (2023). Economic analysis of biomass briquettes made from coconut shells, rattan waste, banana peels and sugarcane bagasse in households cooking. International Journal of Energy and Environmental Engineering, 14(2), 179-187. https://doi.org/10.1007/s40095-022-00508-2

Breyer, C., Heinonen, S., & Ruotsalainen, J. (2017). New consciousness: A societal and energetic vision for rebalancing humankind within the limits of planet Earth. Technological Forecasting and Social Change, 114, 7–15. https://doi.org/10.1016/J.TECHFORE.2016.06.029

Celestino, J. M. T., Lating, P. O., Nabuuma, B., & Yiga, V. A. (2023). Effects of clay, gum Arabic and hybrid binders on the properties of rice and coffee HUSK briquettes. Results in Engineering, 20, 101488. https://doi.org/10.1016/J.RINENG.2023.101488

Chen, S., Ding, H., Tang, Z., Hao, S., & Zhao, Y. (2022). Influence of rice straw forming factors on ring die wear and improved wear prediction model during briquetting. Biosystems Engineering, 214, 122–137. https://doi.org/10.1016/J.BIOSYSTEMSENG.2021.12.012

Chukwuneke, J., Umeji, A., Obika, E., & Fakiyesi, O. (2021). Optimization of composite briquette made from sawdust/rice husk using starch and clay binder. International Journal of Integrated Engineering, 13(4), 208–216. https://doi.org/10.30880/ijie.2021.13.04.019

Choi, J. Y., Nam, J., Yun, B. Y., Kim, Y. U., & Kim, S. (2022). Utilization of corn cob, an essential agricultural residue difficult to disposal: Composite board manufactured improved thermal performance using microencapsulated PCM. Industrial Crops and Products, 183, 114931. https://doi.org/10.1016/j.indcrop.2022.114931

Dinesha, P., Kumar, S., & Rosen, M. A. (2019). Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technology, 7(5), 1801011. https://doi.org/10.1002/ENTE.201801011

El-Desouky, M. G., Khalil, M. A., El-Bindary, A. A., & El-Bindary, M. A. (2022). Biological, biochemical and thermochemical techniques for biofuel production: An updated review. Biointerface Research in Applied Chemistry, 12(3), 3034–3054. https://doi.org/10.33263/BRIAC123.30343054

Eling, J., Okot, D. K., Menya, E., & Atim, M. R. (2024). Densification of raw and torrefied biomass: A review. Biomass and Bioenergy, 184, 107210. https://doi.org/10.1016/J.BIOMBIOE.2024.107210

Espuelas, S., Marcelino, S., Echeverría, A. M., del Castillo, J. M., & Seco, A. (2020). Low energy spent coffee grounds briquetting with organic binders for biomass fuel manufacturing. Fuel, 278, 118310. https://doi.org/10.1016/J.FUEL.2020.118310

FAO. (2023). FAO Publications Catalogue 2023. https://doi.org/10.4060/CC7285EN

Felfli, F. F., Mesa P, J. M., Rocha, J. D., Filippetto, D., Luengo, C. A., & Pippo, W. A. (2011). Biomass briquetting and its perspectives in Brazil. Biomass and Bioenergy, 35(1), 236–242. https://doi.org/10.1016/J.BIOMBIOE.2010.08.011

Ferrera-Lorenzo, N., Fuente, E., Bermúdez, J. M., Suárez-Ruiz, I., & Ruiz, B. (2014). Conventional and microwave pyrolysis of a macroalgae waste from the Agar–Agar industry. Prospects for bio-fuel production. Bioresource Technology, 151, 199–206. https://doi.org/10.1016/J.BIORTECH.2013.10.047

Ferronato, N., Calle Mendoza, I. J., Ruiz Mayta, J. G., Gorritty Portillo, M. A., Conti, F., & Torretta, V. (2022). Biomass and cardboard waste-based briquettes for heating and cooking: Thermal efficiency and emissions analysis. Journal of Cleaner Production, 375, 134111. https://doi.org/10.1016/J.JCLEPRO.2022.134111

Florentino-Madiedo, L., Díaz-Faes, E., Barriocanal, C., Castro-Díaz, M., & Snape, C. E. (2018). Importance of Biomass and Binder Selection for Coking Briquette Preparation. Their Effect on Coal Thermoplastic Properties. Energy and Fuels, 32(10), 10727–10736. https://doi.org/10.1021/ACS.ENERGYFUELS.8B02555

Gilvari, H., de Jong, W., & Schott, D. L. (2019). Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors - A review. Biomass and Bioenergy, 120, 117–134. https://doi.org/10.1016/J.BIOMBIOE.2018.11.013

Givi, A. N., Rashid, S. A., Aziz, F. N. A., & Salleh, M. A. M. (2010). Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Construction and building materials, 24(11), 2145-2150. https://doi.org/10.1016/j.conbuildmat.2010.04.045

Granado, M. P. P., Suhogusoff, Y. V. M., Santos, L. R. O., Yamaji, F. M., & De Conti, A. C. (2021a). Effects of pressure densification on strength and properties of cassava waste briquettes. Renewable Energy, 167, 306–312. https://doi.org/10.1016/j.renene.2020.11.087

Granado, M. P. P., Suhogusoff, Y. V. M., Santos, L. R. O., Yamaji, F. M., & De Conti, A. C. (2021b). Effects of pressure densification on strength and properties of cassava waste briquettes. Renewable Energy, 167, 306–312. https://doi.org/10.1016/J.RENENE.2020.11.087

Han, J., Liu, X., Hu, S., Zhang, N., Wang, J., & Liang, B. (2023). Optimization of decoupling combustion characteristics of coal briquettes and biomass pellets in household stoves. Chinese Journal of Chemical Engineering, 59, 182–192. https://doi.org/10.1016/J.CJCHE.2022.12.012

Hansted, A. L. S., Boschert, C., Hawboldt, K. A., Newell, W. J., & Yamaji, F. M. (2024). Impact of densification process on unprocessed biomass and post-hydrothermal carbonization. Biomass and Bioenergy, 184. https://doi.org/10.1016/j.biombioe.2024.107203

Haq, I. U., Qaisar, K., Nawaz, A., Akram, F., Mukhtar, H., Zohu, X., Xu, Y., Mumtaz, M. W., Rashid, U., Ghani, W. A. K., & Choong, T. S. Y. (2021). Advances in Valorization of Lignocellulosic Biomass towards Energy Generation. Catalysts, 11(3), 309. https://doi.org/10.3390/CATAL11030309

Helwani, Z., Ramli, M., Rusyana, A., Marlina, M., Fatra, W., Idroes, G. M., Suhendra, R., Ashwie, V., Mahlia, T. M. I., & Idroes, R. (2020). Alternative briquette material made from palm stem biomass mediated by glycerol crude of biodiesel byproducts as a natural adhesive. Processes, 8(7). https://doi.org/10.3390/pr8070777

Hoyos Álvarez, C. A., González Doria, Y. E., Mendoza Fandiño, J. M., Hoyos Álvarez, C. A., González Doria, Y. E., & Mendoza Fandiño, J. M. (2019). Elaboración de biocombustibles sólidos densificados a partir de la mezcla de dos biomasas residuales, un aglomerante a base de yuca y carbón mineral, propios del departamento de Córdoba. Ingeniare. Revista Chilena de Ingeniería, 27(3), 454–464. https://doi.org/10.4067/S0718-33052019000300454

Ibitoye, S. E., Jen, T.-C., Mahamood, R. M., & Akinlabi, E. T. (2021). Densification of agro-residues for sustainable energy generation: an overview. Bioresour. Bioprocess, 8, 75. https://doi.org/10.1186/s40643-021-00427-w

Ikelle, I. I., Sule, O., & Ivoms, P. (2014). Determination of the Heating Ability of Coal and Corn Cob Briquettes. Determination of the Heating Ability of Coal and Corn Cob Briquettes. Article in IOSR Journal of Applied Chemistry, 7(2), 77–82. https://doi.org/10.9790/5736-07217782

Ikubanni, P., Tobiloba, O., Ofoegbu, W., Omoworare, O., Pelumi, I. P., Wallace, O., Oluwatoba, O., Akanni, A. A., Oluwole, A. O., & Sola, O. T. (2019). Performance Evaluation of Briquette Produced from a Designed and Fabricated Piston-Type Briquetting Machine. In International Journal of Engineering Research and Technology, 12(8), 1227-1238.

ISO 18134-2 (2017). Solid biofuels - Determination of moisture content - Oven dry method. Part 2: Total moisture - Simplified method. ISO International.

Kalak, T. (2023). Potential use of industrial biomass waste as a sustainable energy source in the future. Energies, 16(4), 1783. https://doi.org/10.3390/en16041783

Kaliyan, N., & Morey, R. V. (2010). Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresource Technology, 101(3), 1082–1090. https://doi.org/10.1016/J.BIORTECH.2009.08.064

Kaliyan, N., & Vance Morey, R. (2009). Factors affecting strength and durability of densified biomass products. Biomass and Bioenergy, 33(3), 337–359. https://doi.org/10.1016/J.BIOMBIOE.2008.08.005

Khlifi, S., Lajili, M., Belghith, S., Mezlini, S., Tabet, F., & Jeguirim, M. (2020). Briquettes production from olive mill waste under optimal temperature and pressure conditions: Physico-chemical and mechanical characterizations. Energies, 13(5), 1214. https://doi.org/10.3390/EN13051214

Kong, L., Tian, S. H., Li, Z., Luo, R., Chen, D., Tu, Y. T., & Xiong, Y. (2013). Conversion of recycled sawdust into high HHV and low NOx emission bio-char pellets using lignin and calcium hydroxide blended binders. Renewable Energy, 60, 559–565. https://doi.org/10.1016/J.RENENE.2013.06.004

Kpalo, S. Y., Zainuddin, M. F., Manaf, L. A., & Roslan, A. M. (2020). A review of technical and economic aspects of biomass briquetting. Sustainability, 12(11), 4609. https://doi.org/10.3390/SU12114609

Kumar, J. A., Kumar, K. V., Petchimuthu, M., Iyahraja, S., & Kumar, D. V. (2021). Comparative analysis of briquettes obtained from biomass and charcoal. Materials Today: Proceedings, 45, 857–861. https://doi.org/10.1016/J.MATPR.2020.02.918

Li, Y., Chen, H., Hammam, A., Wei, H., Nie, H., Ding, W., Omran, M., Yan, L., & Yu, Y. (2021). Study of an organic binder of cold-bonded briquettes with two different iron bearing materials. Materials, 14(11), 2952. https://doi.org/10.3390/MA14112952

Li, Y., Zang, Y., Xiong, Y., Qiu, D., Wang, C., Yan, L., & Yu, Y. (2023). Effect of briquetting pressure on the properties, reduction behavior, and reduction kinetics of cold-bonded briquette prepared from return fines of sinter. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 54(1), 355–369. https://doi.org/10.1007/s11663-022-02696-y

Lü, J., Sheahan, C., & Fu, P. (2011). Metabolic engineering of algae for fourth generation biofuels production. Energy & Environmental Science, 4(7), 2451–2466. https://doi.org/10.1039/C0EE00593B

Lubwama, M., Yiga, V. A., Muhairwe, F., & Kihedu, J. (2020). Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renewable Energy, 148, 1002–1016. https://doi.org/10.1016/j.renene.2019.10.085

Maitah, M., Prochazka, P., Pachmann, A., Šrédl, K., & Řezbová, H. (2016). Economics of palm oil empty fruit bunches bio briquettes in Indonesia. International Journal of Energy Economics and Policy, 6(1), 35-38.

Malnar, M., Radojičić, V., Kulić, G., Dinić, Z., & Cvetković, O. (2023). Energy and emission properties of burley tobacco stalk briquettes and its combinations with other biomass as promising replacement for coal. Arhiv Za Higijenu Rada i Toksikologiju, 74(1), 61–68. https://doi.org/10.2478/aiht-2023-74-3630

Marangon, B. B., Calijuri, M. L., Castro, J. de S., & Assemany, P. P. (2021). A life cycle assessment of energy recovery using briquette from wastewater grown microalgae biomass. Journal of Environmental Management, 285. https://doi.org/10.1016/j.jenvman.2021.112171

Marreiro, H. M. P., Peruchi, R. S., Lopes, R. M. B. P., Andersen, S. L. F., Eliziário, S. A., & Junior, P. R. (2021). Empirical studies on biomass briquette production: A literature review. Energies, 14(24), 8320. https://doi.org/10.3390/EN14248320

Mehedintu, A., Sterpu, M., & Soava, G. (2018). Estimation and forecasts for the share of renewable energy consumption in final energy consumption by 2020 in the European Union. Sustainability, 10(5), 1515. https://doi.org/10.3390/SU10051515

Mendoza Martinez, C. L., Sermyagina, E., de Cassia Oliveira Carneiro, A., Vakkilainen, E., & Cardoso, M. (2019). Production and characterization of coffee-pine wood residue briquettes as an alternative fuel for local firing systems in Brazil. Biomass and Bioenergy, 123, 70–77. https://doi.org/10.1016/j.biombioe.2019.02.013

Miao, Z., Zhang, P., Li, M., Wan, Y., & Meng, X. (2023). Briquette preparation with biomass binder. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 45(4), 9834–9844. https://doi.org/10.1080/15567036.2019.1682722

Midhun, V. C., Jayaprasad, G., Anto, A., & Anish, R. (2023). Preparation and characterisation study of water hyacinth briquettes. Materials Today: Proceedings. https://doi.org/10.1016/J.MATPR.2023.07.157

Mitan, N. M. M., Azmi, A. H., Fathiah, M. N. N., & Se, S. M. (2015). Binder application in durian peels briquette as a solid biofuel. Applied Mechanics and Materials, 761, 494–498. https://doi.org/10.4028/www.scientific.net/amm.761.494

Mitchual, S. J., Frimpong-Mensah, K., Darkwa, N. A., Mitchual, S. J., Frimpong-Mensah, K., & Darkwa, N. A. (2014). Relationship between physico-mechanical properties, compacting pressure and mixing proportion of briquettes produced from maize Cobs and Sawdust. Journal of Sustainable Bioenergy Systems, 4(1), 50–60. https://doi.org/10.4236/JSBS.2014.41005

Muazu, R. I., & Stegemann, J. A. (2017). Biosolids and microalgae as alternative binders for biomass fuel briquetting. Fuel, 194, 339–347. https://doi.org/10.1016/J.FUEL.2017.01.019

Navalta, C. J. L. G., Banaag, K. G. C., Raboy, V. A. O., Go, A. W., Cabatingan, L. K., & Ju, Y. H. (2020). Solid fuel from co-briquetting of sugarcane bagasse and rice bran. Renewable Energy, 147, 1941–1958. https://doi.org/10.1016/J.RENENE.2019.09.129

Nazari, M. M., Idroas, M. Y., & Miskam, M. A. (2022). Effects of organic and inorganic binders on the carbonized empty fruit bunch (EFB) briquette properties. AIP Conference Proceedings, 2541(1). https://doi.org/10.1063/5.0117528/2828953

Nganko, J. M., Koffi, E. P. M., Gbaha, P., Toure, A. O., Kane, M., Ndiaye, B., Faye, M., Nkounga, W. M., Tiogue Tekounegning, C., Bile, E. E. J., & Yao, K. B. (2024). Modeling and optimization of compaction pressure, binder percentage and retention time in the production process of carbonized sawdust-based biofuel briquettes using response surface methodology (RSM). Heliyon, 10(3). https://doi.org/10.1016/j.heliyon.2024.e25376

Niño, A., Arzola, N., & Araque, O. (2020). Experimental study on the mechanical properties of biomass briquettes from a mixture of rice husk and pine sawdust. Energies, 13(5). https://doi.org/10.3390/en13051060

Nurek, T., Gendek, A., Roman, K., & Dąbrowska, M. (2019). The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass and Bioenergy, 130, 105368. https://doi.org/10.1016/J.BIOMBIOE.2019.105368

Okwu, M. O., & Samuel, O. D. (2018). Adapted hyacinth briquetting machine for mass production of briquettes. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 40(23), 2853–2866. https://doi.org/10.1080/15567036.2018.1512681

Olugbade, T. O., & Ojo, O. T. (2021). Binderless briquetting technology for lignite briquettes: a review. Energy, Ecology and Environment, 6(1), 69–79. https://doi.org/10.1007/s40974-020-00165-3

Olugbade, T., Ojo, O., & Mohammed, T. (2019). Influence of binders on combustion properties of biomass briquettes: A recent review. BioEnergy Research, 12(2), 241–259. https://doi.org/10.1007/S12155-019-09973-W

Omoniyi, T. E., & Igbo. (2016). Physico-mechanical characteristics of rice husk briquettes using different binders. Agricultural Engineering International: CIGR Journal, 18(1), 70–81.

Onukak, I. E., Mohammed-Dabo, I. A., Ameh, A. O., Okoduwa, S. I. R., & Fasanya, O. O. (2017). Production and characterization of biomass briquettes from tannery solid waste. Recycling, 2(4), 17. https://doi.org/10.3390/RECYCLING2040017

Ossei-Bremang, R. N., Adjei, E. A., Kemausuor, F., Mockenhaupt, T., & Bar-Nosber, T. (2024). Effects of compression pressure, biomass ratio and binder proportion on the calorific value and mechanical integrity of waste-based briquettes. Bioresource Technology Reports, 25, 101724. https://doi.org/10.1016/J.BITEB.2023.101724

Pardey, P. G., Beddow, J. M., Hurley, T. M., Beatty, T. K. M., & Eidman, V. R. (2014). A bounds analysis of world food futures: Global agriculture through to 2050. Australian Journal of Agricultural and Resource Economics, 58, 571–589. https://doi.org/10.1111/1467-8489.12072

Pari, G., Efiyanti, L., Darmawan, S., Saputra, N. A., Hendra, D., Adam, J., Inkriwang, A., & Effendi, R. (2023). Initial ignition time and calorific value enhancement of briquette with added pine resin. Journal of the Korean Wood Science and Technology, 51(3), 207–221. https://doi.org/10.5658/WOOD.2023.51.3.207

Petricoski, S. M., Feiden, A., Ferla De Oliveira, A., Tokura, L. K., Antonio, J., Siqueira, C., Bonassa, G., Zilli, B. M., Gentelini-Marquez, D. P., Melegari De Souza, S. N., Feiden, C. A., Feiden, E. A., Da, A., & Martinez, S. (2020). Briquettes produced with a mixture of urban pruning waste, glycerin and cassava processing residue. Journal of Agricultural Science, 12(6), 158. https://doi.org/10.5539/jas.v12n6p158

Phaenark, C., Jantrasakul, T., Paejaroen, P., Chunchob, S., & Sawangproh, W. (2023). Sugarcane bagasse and corn stalk biomass as a potential sorbent for the removal of Pb (II) and Cd (II) from aqueous solutions. Trends in Sciences, 20(2), 6221-6221. https://doi.org/10.48048/tis.2023.6221

Pishvaee, M. S., Mohseni, S., & Bairamzadeh, S. (2020). Biomass to biofuel supply chain design and planning under uncertainty: Concepts and quantitative methods. Biomass to Biofuel Supply Chain Design and Planning under Uncertainty: Concepts and Quantitative Methods, 1–271. https://doi.org/10.1016/C2019-0-01795-5

Quijera, J. A., Alriols, M. G., & Labidi, J. (2011). Integration of a solar thermal system in a dairy process. Renewable Energy, 36(6), 1843–1853. https://doi.org/10.1016/J.RENENE.2010.11.029

Rahaman, S. A., & Salam, P. A. (2017). Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Processing Technology, 158, 9–19. https://doi.org/10.1016/j.fuproc.2016.12.008

Rajaseenivasan, T., Srinivasan, V., Syed Mohamed Qadir, G., & Srithar, K. (2016). An investigation on the performance of sawdust briquette blending with neem powder. Alexandria Engineering Journal, 55(3), 2833–2838. https://doi.org/10.1016/J.AEJ.2016.07.009

Ramalingam, G., Priya, A. K., Gnanasekaran, L., Rajendran, S., & Hoang, T. K. A. (2024). Biomass and waste derived silica activated carbon and ammonia-based materials for energy-related applications – A review. Fuel, 355, 129490. https://doi.org/10.1016/J.FUEL.2023.129490

Rao, S., Chirkov, V., Dentener, F., van Dingenen, R., Pachauri, S., Purohit, P., Amann, M., Heyes, C., Kinney, P., Kolp, P., Klimont, Z., Riahi, K., & Schoepp, W. (2012). Environmental modeling and methods for estimation of the global health impacts of air pollution. Environmental Modeling and Assessment, 17(6), 613–622. https://doi.org/10.1007/S10666-012-9317-3

Rezania, S., Md Din, M. F., Kamaruddin, S. F., Taib, S. M., Singh, L., Yong, E. L., & Dahalan, F. A. (2016). Evaluation of water hyacinth (Eichhornia crassipes) as a potential raw material source for briquette production. Energy, 111, 768–773. https://doi.org/10.1016/J.ENERGY.2016.06.026

Romanach, L., & Frederiks, E. (2021). Understanding the key determinants of residential firewood consumption in Australia: A nationwide household survey. Energies, 14(20), 6777. https://doi.org/10.3390/EN14206777/S1

Saptoadi, H. (2008). The best biobriquette dimension and its particle size. Asian J. Energy Environ., 9(3, 4), 161-175.

Sarkar, N., Ghosh, S. K., Bannerjee, S., & Aikat, K. (2012). Bioethanol production from agricultural wastes: An overview. Renewable Energy, 37(1), 19–27. https://doi.org/10.1016/J.RENENE.2011.06.045

Seco, A., Espuelas, S., Marcelino, S., Echeverría, A. M., & Prieto, E. (2020). Characterization of biomass briquettes from spent coffee grounds and xanthan gum using low pressure and temperature. Bioenergy Research, 13(1), 369–377. https://doi.org/10.1007/s12155-019-10069-8

Setter, C., Ataíde, C. H., Mendes, R. F., & de Oliveira, T. J. P. (2021). Influence of particle size on the physico-mechanical and energy properties of briquettes produced with coffee husks. Environmental Science and Pollution Research, 28(7), 8215–8223. https://doi.org/10.1007/S11356-020-11124-0

Shabani, N., & Sowlati, T. (2013). A mixed integer non-linear programming model for tactical value chain optimization of a wood biomass power plant. Applied Energy, 104, 353–361. https://doi.org/10.1016/J.APENERGY.2012.11.013

Solano, D., Vinyes, P., & Arranz, P. (2016). Biomass briquetting process (A guideline report). A UNDP/Cedro, 12, 3034–3054.

Sotannde, O. A., Oluyege, A. O., & Abah, G. B. (2010). Physical and combustion properties of briquettes from sawdust of Azadirachta indica. Journal of Forestry Research, 21(1), 63–67. https://doi.org/10.1007/S11676-010-0010-6

Sun, B., Yu, J., Tahmasebi, A., & Han, Y. (2014). An experimental study on binderless briquetting of Chinese lignite: Effects of briquetting conditions. Fuel Processing Technology, 124, 243–248. https://doi.org/10.1016/J.FUPROC.2014.03.013

Sunnu, A. K., Adu-Poku, K. A., & Ayetor, G. K. (2023). Production and Characterization of Charred Briquettes from Various Agricultural Waste. Combustion Science and Technology, 195(5), 1000–1021. https://doi.org/10.1080/00102202.2021.1977803

Velusamy, S., Subbaiyan, A., Kandasamy, S., Shanmugamoorthi, M., & Thirumoorthy, P. (2022). Combustion characteristics of biomass fuel briquettes from onion peels and tamarind shells. Archives of Environmental and Occupational Health, 77(3), 251–262. https://doi.org/10.1080/19338244.2021.1936437

Velusamy, S., Subbaiyan, A., & Thangam, R. S. (2021). Combustion characteristics of briquette fuels from sorghum panicle–pearl millets using cassava starch binder. Environmental Science and Pollution Research, 28(17), 21471–21485. https://doi.org/10.1007/S11356-020-11790-0

Velusamy, S., Subbaiyan, A., Kandasamy, S., Shanmugamoorthi, M., & Thirumoorthy, P. (2022). Combustion characteristics of biomass fuel briquettes from onion peels and tamarind shells. Archives of Environmental & Occupational Health, 77(3), 251-262. https://doi.org/10.1080/19338244.2021.1936437

Velvizhi, G., Jacqueline, P. J., Shetti, N. P., K, L., Mohanakrishna, G., & Aminabhavi, T. M. (2023). Emerging trends and advances in valorization of lignocellulosic biomass to biofuels. Journal of Environmental Management, 345, 118527. https://doi.org/10.1016/J.JENVMAN.2023.118527

Vivek, C. P., Rochak, P. V, Sagar Suresh, P., -, al, Hendri, N., Sari, D. Y., Mirzayanti, Y. W., Bhismoko, B., Utchariyajit, K., Panprasert, V., Chayawat, L., Jungthanasombat, W., Janprom, P., & Choatchuang, M. (2019). Physical properties and calorific value of briquettes produced from Palmyra palm waste with molasses binder. IOP Conference Series: Materials Science and Engineering, 639(1), 012046. https://doi.org/10.1088/1757-899X/639/1/012046

Wang, L., Fan, R., Yan, Y., Yang, S., Wang, X., & Zheng, B. (2023). Characterization of the structural, physicochemical, and functional properties of soluble dietary fibers obtained from the peanut shell using different extraction methods. Frontiers in Nutrition, 9, 1103673. https://doi.org/10.3389/fnut.2022.1103673

Yang, I., Cooke-Willis, M., Song, B., & Hall, P. (2021). Densification of torrefied Pinus radiata sawdust as a solid biofuel: Effect of key variables on the durability and hydrophobicity of briquettes. Fuel Processing Technology, 214. https://doi.org/10.1016/j.fuproc.2020.106719

Yilma, H., Nasirudeen, M., Binin, M., & Abdulrahman, B. (2023). Production of blended biomass/coal briquettes for domestic energy used. International Journal of Multidisciplinary Research and Growth Evaluation, 4(3), 299-303.

Yusuf Kpalo, S., & Faiz Zainuddin, M. (2020). Briquettes from agricultural residues; an alternative clean and sustainable fuel for domestic cooking in Nasarawa State, Nigeria. Energy and Power, 10(2), 40–47. https://doi.org/10.5923/J.EP.20201002.03

Zhang, J., & Guo, Y. (2014). Physical properties of solid fuel briquettes made from Caragana korshinskii Kom. Powder Technology, 256, 293–299. https://doi.org/10.1016/J.POWTEC.2014.02.025

Zhang, J., Zheng, D., Wu, K., & Zhang, X. (2019). The optimum conditions for preparing briquette made from millet bran using generalized distance function. Renewable Energy, 140, 692–703. https://doi.org/10.1016/J.RENENE.2019.03.079

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2025 Scientia Agropecuaria

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial 4.0.

Los autores que publican en esta revista aceptan los siguientes términos:

a. Los autores conservan los derechos de autor y conceden a la revista el derecho publicación, simultáneamente licenciada bajo una licencia de Creative Commons que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

b. Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

c. Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (ver efecto del acceso abierto).