Energy efficiency of heating machines and its effects on broiler's performance and welfare

DOI:

https://doi.org/10.17268/sci.agropecu.2025.017Palabras clave:

poultry production, thermal comfort, heat system, productivity, gases concentrationResumen

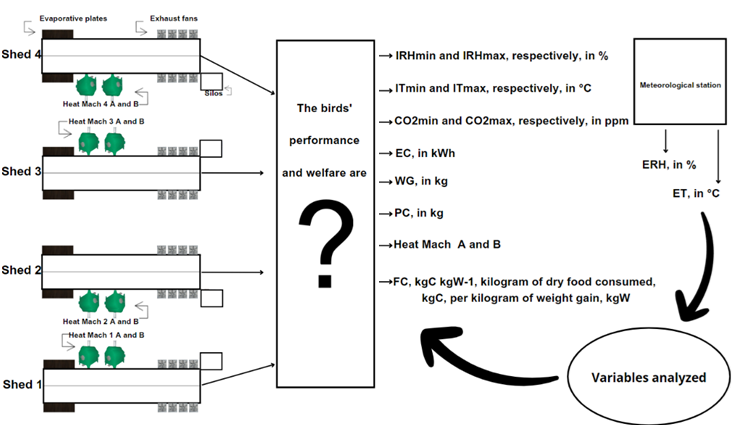

The increasing global demand for animal protein has driven the broiler industry to optimize production systems and better understand limiting factors affecting performance. This study evaluated four different heating systems to determine their correlation with climatic variables, zootechnical performance, pellet fuel consumption, and energy usage. Data were obtained from a private broiler integration company in Southwest Paraná, Brazil, specializing in the griller broiler category. The study covered a 28-day housing period for 12 flocks (both male and female), each consisting of approximately 120,000 birds, for 28 days. The analyzed variables included indoor and outdoor environmental temperature, relative air humidity, carbon dioxide (CO₂) concentration inside the poultry houses, feed conversion ratio, weight gain, pellet fuel consumption, and energy consumption. Statistical analyses were performed using descriptive statistics and Principal Component Analysis (PCA) in R software. Results indicated that correlations among variables were generally weak. However, environmental conditions had the greatest influence on broiler performance. The first principal component explained 74.1% of the total variance, with minimum CO₂ concentration, external temperature, minimum and maximum internal temperature, and pellet fuel consumption being key contributing factors. The second principal component included maximum CO₂ concentration, weight gain, and minimum internal and external relative humidity. Among the evaluated heating systems, the fourth machine tested exhibited the lowest pellet fuel consumption while maintaining satisfactory weight gain and feed conversion rate despite its relatively high energy consumption. These findings suggest that temperature control and pellet fuel consumption are critical factors in optimizing broiler production efficiency, ultimately contributing to improved growth performance and resource utilization.

Citas

ABPA. (2020). Annual report. Brazilian Association of Animal Protein. https://abpa-br.org/wp-content/uploads/2022/02/abpa-relatorio-anual-2020.pdf

Alvares, C. A., Stape, J. L., Sentelhas, P. C., & Gonçalves, J. L. M. (2013). Modeling monthly mean air temperature for Brazil. Theoretical and Applied Climatology, 113(3-4), 407-427. https://doi.org/10.1007/s00704-012-0799-2.

Apalowo, O. O., Ekunseitan, D. A., & Fasina, Y. O. (2024). Impact of heat stress on broiler chicken production. Poultry, 3(2), 107-128. https://doi.org/10.3390/poultry3020010

Baêta, F. C., & Souza, C. F. (2010). Ambiência em edificações rurais: conforto animal (2nd ed.). Viçosa: Editora UFV.

Barbosa Filho, J. A., Almeida, M., Shimokomaki, M., Pinheiro, J. W., Silva, C. A., Michelan Filho, T., & Oba, A. (2017). Growth performance, carcass characteristics, and meat quality of griller-type broilers of four genetic lines. Brazilian Journal of Poultry Science, 19, 109-114. https://doi.org/10.1590/1806-9061-2016-0310

Barbosa, R. C., Dalólio, F. S., Amorim, M. L., Silva, J. N., & Gonzaga, D. A. (2017). Analysis of economic feasibility of heating systems in agricultural facilities during broiler breeding. Revista Engenharia na Agricultura, 25(3), 212-222. https://doi.org/10.13083/reveng.v25i3.780

Bendheim, U., Berman, E., & Zadikov, I. (1992). The effects of poor ventilation, low temperatures, type of feed, and sex of bird on the development of ascites in broilers. Avian Pathology, 21(3), 383-388. https://doi.org/10.1080/03079459208418854

Butcher, G. D., & Nilipour, A. H. (2005). Broiler production goals - important numbers: VM134/VM099. https://edis.ifas.ufl.edu/publication/VM099

Cassuce, D. C., Tinôco, I. F. F., Baêta, F. C., Zolnier, S., Cecon, P. R., & Vieira, M. F. A. (2013). Thermal comfort temperature update for broiler chickens up to 21 days of age. Engenharia Agrícola, 33, 28-36. https://doi.org/10.1590/S0100-69162013000100004

Chand, N., Muhammad, S., Khan, R. U., Alhidary, I. A., & Rehman, Z. U. (2016). Ameliorative effect of synthetic gamma-aminobutyric acid (GABA) on performance traits, antioxidant status, and immune response in broilers exposed to cyclic heat stress. Environmental Science and Pollution Research, 23, 23930-23935. https://doi.org/10.1007/s11356-016-7604-2

Choi, H. C., Salim, H. M., Akter, N., Na, J. C., Kang, H. K., Kim, M. J., Kim, D. W., Bang, H. T., Chae, H. S., & Suh, O. S. (2012). Effect of heating system using a geothermal heat pump on the production performance and housing environment of broiler chickens. Poultry Science, 91, 275-281. https://doi.org/10.3382/ps.2011-01573

COBB. (2021). Cobb broilers – management guide. Cobb-Vantress. https://www.cobb-vantress.com/assets/Cobb-Files/045bdc8f45/Broiler-Guide-2021-min.pdf

Cordeiro, M. B., Tinôco, I. F. F., Silva, J. N., Vigoderis, R. B., Pinto, F. A. C., & Cecon, P. R. (2010). Conforto térmico e desempenho de pintos de corte submetidos a diferentes sistemas de aquecimento no período de inverno. Revista Brasileira de Zootecnia, 39(1), 217-224. https://doi.org/10.1590/S1516-35982010000100030

Cordeiro, M. B., Tinôco, I. F. F., Mesquita Filho, R. M., & Sousa, F. C. (2011). Digital image analysis for young chicken's behavior evaluation. Engenharia Agrícola, 31(3), 418-426. https://doi.org/10.1590/S0100-69162011000300003

Cui, Y., Theo, E., Gurler, T., Su, Y., & Saffa, R. (2020).A comprehensive review on renewable and sustainable heating systems for poultry farming. International Journal of Low-Carbon Technologies, 15, 121–142, https://doi.org/10.1093/ijlct/ctz048

Cui, Y., Xue, X., & Riffat, S. (2021). Cost Effectiveness of Poultry Production by Sustainable and Renewable Energy Source. IntechOpen. . https://doi.org/10.5772/intechopen.97543

Czarick, M., & Fairchild, B. (2012). Relative humidity: the best measure of overall poultry house air quality. https://www.poultryventilation.com/wp-content/uploads/vol24n2.pdf

El Boushy, A. R., & Van Marle, A. L. (1978). The effect of climate on poultry physiology in tropics and their improvement. World Poultry Science Journal, 34, 155-171. https://doi.org/10.1017/S0043933907000268

EMBRAPA. (2021). Custos de produção de frangos de corte e de suínos acumulam alta de mais de 48% nos últimos 12 meses. Empresa Brasileira de Pesquisa Agropecuária. https://www.embrapa.br/busca-de-noticias/-/noticia/60135950/custos-de-producao-de-frangos-de-corte-e-de-suinos-acumulam-alta-de-mais-de-48-nos-ultimos-12-meses

Ferreira, R. A. (2011). Maior produção com melhor ambiente: para aves, suínos e bovinos. Viçosa: Editora Aprenda Fácil.

Handayani, D., Haryono, H., Prihatiningsih, T., Hikmah, N. (2025). Evaluation of the Performance of Automatic Temperature Control Technology in a Closed House Broiler Chicken Production System. Journal of Industrial Engineering and Halal Industries, 5(2), 24–31. https://doi.org/10.14421/jiehis.4954

HFAC Humane Farm Animal Care. (2009). Padrões do HFAC para a produção de Frangos de Corte. Fev.

Hurnik, J. F., Summers, J. D., Walker, J. P., & Szkotnicki, W. (1977). Production traits influencing the individual feed conversion ratio. Poultry Science, 56(3), 912-917. https://doi.org/10.3382/ps.0560912

Ismail, R. I., Khor, C. Y., & Mohamed, A. R. (2023). Pelletization temperature and pressure effects on the mechanical properties of Khaya senegalensis biomass energy pellets. Sustainability, 15(9), 7501. https://doi.org/10.3390/su15097501

Jones, T. A., Donnelly, C. A., & Stamp, D. M. (2005). Environmental and management factors affecting the welfare of chickens on commercial farms in the United Kingdom and Denmark stocked at five densities. Poultry Science, 84, 1155-1165. https://doi.org/10.1093/ps/84.7.1155

Kanjilal, D., Singh, D., Reddy, R., & Mathew, J. (2014). Smart farm: extending automation to the farm level. International Journal of Scientific & Technology Research, 3(7), 109-113.

Ledesma, R., Valero-Mora, P., & Macbeth, G. (2015). The scree test and the number of factors: a dynamic graphics approach. The Spanish Journal of Psychology, 18, E11. https://doi.org/10.1017/sjp.2015.1

Leite, C. D. S., Corrêa, G. S. S., Barbosa, L., Melo, A. L. P., Yamaki, M., Silva, M. A., & Torres, R. A. (2009). Avaliação de características de desempenho e de carcaça de codornas de corte por meio da análise de componentes principais. Arquivo Brasileiro de Medicina Veterinária e Zootecnia, 61(2), 498-503. https://doi.org/10.1590/S0102-09352009000200014

Li, S. Z., Ren, B. B., Yang, H. M., Yang, Y. Y., Ji, H., & Ni, J. (2006). Effect of cold stress with different intensities on HSP70 expression in Wistar rat muscle, spleen, and liver. Chinese Journal of Applied Environmental Biology, 12, 235-238.

Line, J. E. (2006). Influence of relative humidity on transmission of Campylobacter jejuni in broiler chickens. Poultry Science, 85(7), 1145-1150. https://doi.org/10.1093/ps/85.7.1145

Lott, B. D., Simmons, J. D., & May, J. D. (1998). The effect of environmental temperature and body weight on growth rate and feed: gain ratio of broilers. Poultry Science, 77(3), 347-351. https://doi.org/10.1093/ps/77.3.347

Olanrewaju, H. A., Dozier, W. A., Purswell, J. L., Branton, S. L., Miles, D. M., Lott, B. D., Pescatore, A. J., & Thaxton, J. P. (2008). Growth performance and physiological variables for broiler chickens subjected to short-term elevated carbon dioxide concentrations. International Journal of Poultry Science, 7, 738-742. https://doi.org/10.3923/ijps.2008.738.742

Pełka, G., Jach-Nocoń, M., Paprocki, M., Jachimowski, A., Luboń, W., Nocoń, A., Wygoda, M., Wyczesany, P., Pachytel, P., & Mirowski, T. (2023). Comparison of emissions and efficiency of two types of burners when burning wood pellets from different suppliers. Energies, 16(4), 1695.

Qiu, Y., Zhou, Y., Chang, Y., Liang, X., Zhang, H., Lin, X., Qing, K., Zhou, X., & Luo, Z. (2022). The effects of ventilation, humidity, and temperature on bacterial growth and bacterial genera distribution. International Journal of Environmental Research in Public Health, 19(22), 15345. https://doi.org/10.3390/ijerph192215345

R Core Team. (2024). R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. Available at: https://www.R-project.org/.

Reece, F. N., & Lott, B. D. (1980). Effect of carbon dioxide on broiler chicken performance. Poultry Science, 59(11), 2400-2402. https://doi.org/10.3382/ps.0592400

Rehman, Z. U., Chand, N., & Khan, R. U. (2018). An assessment of the growth and profitability potential of meat-type broiler strains under high ambient temperature. Pakistan Journal of Zoology, 50(2), 429-435. https://doi.org/10.17582/journal.pjz/2018.50.2.429.435

Ryu, S. T., Park, B. S., Bang, H. T., Kang, H. K., & Hwangbo, J. (2016). Effects of anti-heat diet and inverse lighting on growth performance, immune organ, microorganism and short chain fatty acids of broiler chickens under heat stress. Journal of Environmental Biology, 37(2), 185-192. https://doi.org/10.22438/jeb/37/2/MN-1363

Sesay, A. R. (2022). Impact of heat stress on chicken performance, welfare, and probable mitigation strategies. International Journal of Environment and Climate Change, 12(11), 3120-3133. https://doi.org/10.9734/IJECC/2022/v12i111360

Sgavioli, S., Santos, E. T., Domingues, C. H. D. F., Castiblanco, D. M. C., Rodrigues, P. H. M., Zeferino, C. P., Almeida, A. R., & Boleli, I. C. (2023). Broiler behavior: Influence of thermal stress, age, and period of the day. Revista Brasileira de Zootecnia, 52, p.e20200239. https://doi.org/10.37496/rbz5220200239

Shlosberg, A., Pano, G., Handji, V., & Berman, E. (1992). Prophylactic and therapeutic treatment of ascites in broiler chickens. British Poultry Science, 33(1), 141-148. https://doi.org/10.1080/00071669208417473

Silva, R., Oliveira, D., dos Santos, D. P., Santos, L. F. D., Wilson, R. E., & Bedo, M. (2020). Criteria for choosing the number of dimensions in a principal component analysis: An empirical assessment. Research paper presented at the Simpósio Brasileiro de Banco de Dados (SBBD) 35th Annual Meeting, Porto Alegre, Rio Grande do Sul, 28 September – 1 October 2020. SBBD Annals, 35, 145-150. https://doi.org/10.5555/1234567890

Smith, S., Meade, J., Gibbons, J., McGill, K., Bolton, D., & Whyte, P. (2016). Impact of direct and indirect heating systems in broiler units on environmental conditions and flock performance. Journal of Integrative Agriculture, 15(11), 2588-2595. https://doi.org/10.1016/S2095-3119(16)61351-4 Udeh, I., & Ogbu, C. C. (2011). Principal component analysis of body measurements in three strains of broiler chicken. Science World Journal, 6(2), 11-14. https://doi.org/10.4314/swj.v6i2.68340

Vigoderis, R. B., Cordeiro, M. B., Tinôco, I. D., Menegali, I., Souza Júnior, J. P., & Holanda, M. C. (2010). Avaliação do uso de ventilação mínima em galpões avícolas e de sua influência no desempenho de aves de corte no período de inverno. Revista Brasileira de Zootecnia, 39, 1381-1386. https://doi.org/10.1590/S1516-35982010000600009

WATHES, C. M. Strive for clean air in your poultry house. World Poultry, v.15, n.3, p.17-19, 1999.

Xiong, Y., Meng, Q. S., Jie, G. A., Tang, X. F., & Zhang, H. F. (2017). Effects of relative humidity on animal health and welfare. Journal of Integrative Agriculture, 16(8), 1653-1658. https://doi.org/10.1016/S2095-3119(17)61715-4

Yasmeen, R., Ali, Z., Tyrrel, S., & Nasir, Z. A. (2019). Estimation of particulate matter and gaseous concentrations using low-cost sensors from broiler houses. Environmental Monitoring and Assessment, 191, 1-10. https://doi.org/10.1007/s10661-019-7408-y

Zhang, X., & Tong, H. (2020). Some cautionary comments on principal component analysis for time series data. arXiv, 2008.01496. https://doi.org/10.48550/arXiv.2008.01496

Zhang, Z. Y., Jia, G. Q., Zuo, J. J., Zhang, Y., Lei, J., Ren, L., & Feng, D. Y. (2012). Effects of constant and cyclic heat stress on muscle metabolism and meat quality of broiler breast fillet and thigh meat. Poultry Science, 91, 2931-2937. https://doi.org/10.3382/ps.2012-02336

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2025 Scientia Agropecuaria

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial 4.0.

Los autores que publican en esta revista aceptan los siguientes términos:

a. Los autores conservan los derechos de autor y conceden a la revista el derecho publicación, simultáneamente licenciada bajo una licencia de Creative Commons que permite a otros compartir el trabajo, pero citando la publicación inicial en esta revista.

b. Los autores pueden celebrar acuerdos contractuales adicionales separados para la distribución no exclusiva de la versión publicada de la obra de la revista (por ejemplo, publicarla en un repositorio institucional o publicarla en un libro), pero citando la publicación inicial en esta revista.

c. Se permite y anima a los autores a publicar su trabajo en línea (por ejemplo, en repositorios institucionales o en su sitio web) antes y durante el proceso de presentación, ya que puede conducir a intercambios productivos, así como una mayor citación del trabajo publicado (ver efecto del acceso abierto).