1. Introduction

Around 30000 of the estimated 300000 to 500000 plant species presented in the world are considered edible; although only 7000 of them are consumed by humans (Marrelli et al., 2020). Even though globalization currently allows trading of abundant species in a constant flow, there are those agricultural species that do not reach a global recognition scenario. The main causes of this underutilization have diverse origins: from agronomic factors such as the high cost, in terms of time investment for harvesting some grains, and the short post-harvest life of some fruits; economic circumstances associated with the high transaction cost involved in bringing the products to the market due to the lack of communication infrastructures and incipient marketing systems, up to the low profitability they provide, compared to the improved varieties (Pastor et al., 2006).

Nevertheless, many of these products have properties that could be exploited as new sources of business, rural development, and market growth. In fact, there are a big demand for grains and legumes which were processed by puffing and popping due to their nutritional characteristics (Swarnakar et al., 2022). Regarding the situation in Andean region, one underutilized crop is the "ñuña" bean or popping bean, which it receives this name for the characteristic of bursting when exposed to heat (Cruz Balarezo et al., 2009). In fact, the potential of this type of bean is still little explored as it has not been given importance as an innovative product within the traditional economy of the Andean people; so much so, that it only concentrates on small crops in the highland areas of Peru and Bolivia (Otálora et al., 2006). According to Valladolid (2016), there are seven cultivars of ñuña: ñuña pava, ñuña soya, checche poroto, vaquita poroto, ñuña jabona, ñuña blanca, ñuña negra, all of which are registered by the Ministry of Agriculture and Irrigation of Peru.

The popping process takes place in some grains when heat is applied. The bursting of the grains is caused by vaporization of water in the starch matrix of the grain which increases the temperature and internal pressure, leading to the rupture of the pericarp. In this process, the starch grains gelatinize and the pores expand, resulting in a spongy matrix (Castro-Giráldez et al., 2012). This process also develops different flavors and smells, increasing acceptability by the consumer of the cereal or legume (Llopart & Drago, 2016), that can be an opportunity for the production of new snacks.

The popping property depends on intrinsic characteristics of the grain such as variety, physical properties and composition; and on process conditions as aging and storage, and heating devise (Swarnakar et al., 2022). For instance, it was indicated that a direct selection of the family phenotypes increased the percentage of popping and the coefficient of expansión Vorwald and Nienhuis (2009b). In addition, other work states that the combination of 5% of moisture, chamber temperature of 244 °C and a popping time of 90s resulted in 90% yield percentages for a variety of ñuña beans (Vorwald & Nienhuis, 2009a). Another examples is for sorghum whose popping quality is influenced by environment, genotype, and the genotype-environment interaction (Pugh et al., 2017).

Furthermore, popping methods are important to consider. Electric frying pans, kitchen ovens, and microwave ovens are the three most commonly used appliances in homes and food industries (Gökmen, 2004; Sanchez-Pardo et al., 2012). These devises cause superheating during the popping process due to a pressure vessel inside the pericarp increases, which produces a driving force for expanding the kernel once the pericarp breaks (Hoseney et al., 1983; Puangjinda et al., 2016). When microwave heating is used, expansion occurs due to the vapor pressure inside the grain under an oscillating field of specific frequency in the microwave (Ernoult et al., 2002; Puangjinda et al., 2016). In fact, microwave popped products may not have same expansion compared to conventional methods as heating time is shorter in addition to the uneven heating pattern (Mishra et al., 2014).

Popping yield and expansion are important quality parameters to consider for popping process (Rezaey et al., 2024; Van der Sman & Bows, 2017). To optimize production processes and ensure product quality, it is crucial to understand the physics underlying snack expansion and consider various factors that can influence the process. Factors such as heating conditions and grain properties can impact the expansion steps and final product characteristics. Therefore, controlling microwave power and exposure time is essential to achieve the desired expansion. Furthermore, there is not any work using microwave popping for ñuña changing moisture content of the grain justifying the present research. For those reasons, the present work aimed to study the microwave assisted popping process of five cultivars of ñuña beans controlling microwave power, time and grain’s moisture content.

2. Methodology

2.1 Raw material

Ñuña bean grains were obtained from a local market from Huamachuco -Peru (3200 masl). Almost 2 kg of grains were obtained from each ñuña cultivar: “Negra” (N), “Pava” (P), “Checche poroto” (CP), “Vaquita poroto” (VP), “Jabona” (J). The grains were stored in paper bags after being selected considering uniform size and perfect condition without any damage. They were stored at an average room temperature of 18°C - 20°C, with an initial moisture content wet basis (w.b.) of 8.04%-VP, 8.3%-CP, 8.51%-P, 11.02%-N and 12.85%-J.

2.2 Experimental design

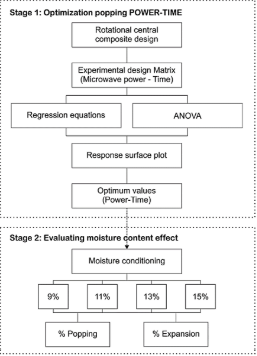

The experimental design was divided into two stages, as shown in Figure 1. In Stage 1, the rotational central composite design was used to study two variables, time (1 - 2 min range), and percentage power of the microwave (40% - 100%), considering 100% of power as 857 ± 20 W. The popping percentage (Section 2.4) was used as the dependent variable to determine the response pattern and stablish the optimum values of independent variables. Table 1 presents the considered levels for each variable range.

Table 1

Surface respond design of the first stage of the experiment

Experiments | Power percentage (%) | Time (min) |

1 | 50 (-1) | 1.09 (-1) |

2 | 90 (1) | 1.09 (-1) |

3 | 50 (-1) | 1.51 (1) |

4 | 90 (1) | 1.51 (1) |

5 | 40 (-1.41) | 1.3 (0) |

6 | 100 (1.41) | 1.3 (0) |

7 | 70 (0) | 1 (-1.41) |

8 | 70 (0) | 2 (1.41) |

9 | 70 (0) | 1.3 (0) |

10 | 70 (0) | 1.3 (0) |

11 | 70 (0) | 1.3 (0) |

The surface respond design allowed to obtain the optimum time and microwave power for each cultivar of ñuña bean regarding their popping percentage yield.

In Stage 2, the effect of grain’s moisture content on popping and expansion percentage of each cultivar of ñuña was studied. The grains were conditioned to 4 levels of grain moisture content (9%, 11%, 13%, 15%) based on the previous model of Vorwald & Nienhuis (2009b) (see section 2.4). Then, the popping percentage and expansion percentage was evaluated for each treatment considering the optimum conditions of microwave power and time determined in the first stage.

Figure 1. Experimental design for the 2 stages of the experiment.

2.3 Microwave popping process

For microwave popping process a sample of grains (100 grains in the first experimental stage and 20 grains in the second experimental stage) were place inside a paper bag. The bags were place inside a Microwave Oven (Oster, Model POGH21402 34L, China) setting the power percentage and the time according to experiments from Table 1 for Stage 1 and considering the optimum values of Power-Time for Stage 2.

2.4 Moisture content conditioning

For studying the moisture content effect on popping quality, the grain’s moisture content was conditioned.

For increasing moisture content (11%, 13% and 15% w.b.), water was added to grains to reach the desired moisture. The added water mass was calculated by mass balance (Equation 1) considering the initial mass of the grains and their initial moisture content obtained by a Moisture Analyzer (OHAUS, model MB45 basic LA, Switzerland). Then, ñuña grains were sprayed with the calculated mass of water and stored in sealed containers under refrigeration conditions (5 °C) for one week to homogenize the moisture.

The equation for mass balance is presented in Equation 1, where  (g) is the mass of water that have to be added to reach the desired moisture content,

(g) is the mass of water that have to be added to reach the desired moisture content,  is the initial moisture content of grains (% w.b.) and

is the initial moisture content of grains (% w.b.) and  is the desired moisture content that grains should reach.

is the desired moisture content that grains should reach.

(Equation 1)

(Equation 1)

On the other hand, the sample with the lowest initial moisture content (9% w.b.) was prepared by placing the grains in a desiccator with silica gel for 2 weeks until obtaining the required moisture content. The mass of the grains was controlled twice a day in order to verify if they reach the required moisture content (determined by mass balance in Equation 2).

(Equation 2)

(Equation 2)

Where  (g) is the mass that grains must reach to reduce their moisture content to

(g) is the mass that grains must reach to reduce their moisture content to  .

.

2.5 Popping Percentage

The popping percentage represents the proportion of beans that successfully burst during heating. The equation proposed by Otálora, Ligarreto, & Romero (2006) was used (Equation 3). In this case, at the Stage I, 100 grains of ñuña were put into a paper bag and placed inside the microwave plate. The different levels of cooking time were controlled. Then, the grains in which the cotyledons broke the testa (seed coat) were counted, and this value was expressed as:

(Equation 3)

(Equation 3)

where N1 is the number of grains with broken seed coat due to the expansion of the cotyledons and N0 is the number of seeds in the original sample. Same procedure was used for the Stage II using only 20 grains of ñuña.

2.6 Volume expansion percentage

A sample of 20 grains of each treatment was taken and the volume of each seed was measured, before and after popping process. For that, the width, length and height were measured using a digital caliper and the volume was determined using Equation 4 (van Beem & Spaeth, 1990).

(Equation 4)

(Equation 4)

where A is the width of the grain; B, the length of the grain; and C, the height of the grain.

(Equation 5)

(Equation 5)

The percentage of expansion (Equation 5) is the rate between grain volume after popping V1 and grain volume before popping V2.

2.7 Statistical evaluation

In the first experimental stage, Rotational Central Composite Design (RCCD) for Surface Respond was applied to determine the best value of microwave power percentage and time to maximize popping percentage. The design and analysis were conducted using STATISCA 7.0 software. For selecting the suitable model (Linear, quadratic with or without interaction), determination coefficients were compared. The best values of microwave power percentage and time were obtained from the best models, fixing values of power percentage (60, 70, 80, 90, 100) and finding the shorter time to obtain the highest popping percentage. It is important to mention that the power percentage were fixed according to the commercial microwave oven power levels (discrete values). This step was performed using the ‘Solver’ tool of Microsoft Excel 2019 (Microsoft, USA).

In the second experimental stage, an analysis of variance was carried out to evaluate the effect of moisture content of the grains on popping percentage and volume expansion of the grains. Then, if necessary, Tukey's mean comparison test was applied to verify the difference between treatments of each variable. Confidence level of 95% was considered.

3. Results and discussion

3.1 Optimization Power-Time microwave popping

Using surface response design methodology considering time and microwave power as variables led to reach high popping percentage for every studied cultivar. This methodology was used before for optimizing rice popping (Mir et al., 2016) and increasing popping yield of red popcorn (Pohndorf et al., 2019). For microwave popping, response surface methodology was used in popping process of paddy (Devi & Das, 2018).

Table 2 shows the determination coefficients (R2) of the four common models that can be use with Central Composite Design. The model that considers the linear and quadratic main effects with the interaction between the independent variables obtained the highest values of R2 for every ñuña bean cultivar. Consequently, this model was selected to plot the respond surfaces showed in Figure 2 and the model parameters are presented in Table 3.

Figure 2 shows that each variable, time and power percentage, had similar effect for each cultivar of ñuña bean. Every respond surface evidenced a tendency to increase popping percentage when the power percentage and time is increased. Regarding Pava and Checche poroto cultivars, the popping percentage was not high as the other cultivars, reaching values less than 80%. In fact, a precise energy (power – time) should be provided to grains for popping since more energy leads to grain damage avoiding it to burst. For instance, this is evidenced for Checche poroto cultivar, where longer times than 1.6 min can reduce popping percentage. In addition, for Jabona cultivar, where higher microwave power can reduce popping percentage. Previous studies with ñuña beans (line PB24) showed similar results regarding increasing popping percentage with popping time up to 1.75 min; however, decreasing after this time (Vorwald & Nienhuis, 2009a)

Similarly, time and microwave power expressed exclusive behaviors in other types of grain. For example, rice needed a popping time of 80 s with a microwave power of 600 W (Devi & Das, 2018) or 120 s of popping time with a microwave power of 800 W (Puangjinda et al., 2016). Controlling time is crucial since, excessive time produces irreversible effect, as, for example, on popcorn quality (Solanki et al., 2018).

Table 4 shows the predicted results of the popping percentage yield for the five studied cultivars considering the optimum values of power and time. The results show that the varieties Negra, Jabona, and Vaquita can achieve a 100% popping percentage, while Pava and Checche poroto achieved a slightly lower popping percentage of 77.1% and 76.9%, respectively. In fact, this reinforces that hereditary genetic of the samples can affect the popping process (Pugh et al., 2017).

The results suggest that the popping characteristics of different bean varieties can vary significantly and that the optimal popping conditions for each cultivar can be predicted using mathematical models based on the variables of power and time.

3.2 Moisture influence in popping process

The effect of 4 different levels of moisture content (9%,11%,13%,15% w.b.) and its effect on popping and expansion percentage of 5 different cultivars of ñuña were investigated. Figure 3 shows that the popping percentage of every studied cultivar was affected by its initial moisture content. In fact, every cultivar evidenced decrease of popping percentage when moisture was higher than 11% w.b. observing a drastic drop at 15% w.b. of moisture content. Therefore, drier grains are desirable to increase popping yield. It is important to mention that other components as starch, protein and fat content could not affect the popping process of ñuña beans as demonstrated in several American cultivars (Rezaey et al., 2024).

Similarly, this behavior follows the pattern presented by Vorwald & Nienhuis (2009a), where found that ñuña grains line “PB24” presented better popping percentage when the moisture content was close to 5%, reducing this percentage as the moisture increase. On the other hand, Rezaey et al. (2024) stated that moisture content had not affected popping yield for the studied cultivars of ñuña beans. However, that work studied a narrow range of moisture content of grains (7.1% - 9.3% w.b.), being the possible reason for why they did not find significant correlation.

Regarding other grains, Srdić et al. (2018) found that the optimal moisture content for popcorn popping was 14% since this resulted in the highest popping volume and lowest percentage of unpopped kernels. Other works suggest the moisture range of 11% to 15.5% as optimal for achieving the highest volume expansion in corn (Anne Allred-Coyle, 2000; de la O-Olán et al., 2018; ERTAŞ et al., 2009; Gökmen, 2004; Shimoni et al., 2002), and ranged between 12% and 14%. for rice (Maisont & Narkrugsa, 2010; Swarnakar et al., 2014). This discrepancy involves and emphasizes that different varieties/cultivars of grains may have distinct optimum moisture content for achieving desirable popping characteristics (de la O-Olán et al., 2018; Vázquez et al., 2011).

The popping mechanism of nuña beans involves the buildup and release of steam pressure within the cellular structure of the cotyledons, specifically within and between the mesophyll cells from cotyledons (Spaeth et al., 1989; Vorwald & Nienhuis, 2009a). According to Vorwald & Nienhuis (2009a), high moisture content of ñuña grains reduced popping due to steam was observed escaping from the surface of unpopped seeds, which may result in adiabatic cooling reducing popping percentage. Another possibility is that seed coat properties change when its moisture content change, i.e. permeability to water increases when seed coat moisture increases (Miano & Augusto, 2015). This could cause moisture to lose by the seed coat avoiding the vapor internal pressure to increase enough for grains bursting.

Regarding expansion percentage after popping, Figure 3 shows that expansion depends on the cultivar and the initial moisture content. Every cultivar, excepting for Checche, increases its volume when popping as moisture content increases. In fact, higher expansion percentage would indicate better quality products since the more expanded grains would have better texture for consumption. For instance, popping volume and percentage of unpopped kernels are very important traits which determine the quality of popcorn. Commercial value of popcorn increases with the higher popping volume, and the lower percentage of unpopped kernels (Srdić et al., 2018). However, despite the expansion percentage tends to be higher on grains with 15% of moisture content, the popping percen-tage is low at this level of moisture. Therefore, there should be a balance between expansion and popping percentage. Previous studies found signifi-cant differences among genotypes concerning popping volume (Srdić et al., 2015), and depen-dence of popping volume on grain moisture (Gökmen, 2004; Srdić et al., 2017; Srdić et al., 2018). Results in popcorn indicated that the highest expansion volumes and flake size values were achieved at 12% moisture content for the Ant Cin-98 and Koç Cin cultivars (ERTAŞ et al., 2009). However, for the Nermin Cin cultivar, the expansion volume increased as the kernel moisture content increased, similar as Gökmen (2004), Metzger et al (1989), Shimoni et al.(2002), Stewart (1923) and Ziegler (2000), where found maximum popping volume at 14%, 13.54% - 14.03%, 15.51%, 15.7% - 16.3% and 13.0% -14.5% of moisture content, respectively. On the other hand, different optimum expansion was obtained at different moisture content for different grains such as brown rice at 8% (Swarnakar et al., 2020), sorghum from 10.90% - 11.51% (Anithasri et al., 2018), and perlet millet from 8.74% - 11.12% (Kumari et al., 2018).

As final consideration, the ñuña cultivar with best popping yield and quality is desirable in order to be produced and comercialized. Therefore, from both stages in this study, the best cultivar could be recommended. From the first stage, we can consider that Vaquita poroto, Negra and Jabona should be selected as they can reach almost 100% of popping percentage at optimun conditions of microwave power and process time.

Moreover, considering results from second stage, from these 3 cultivars, the Vaquita cultivar would be the best because it has the highest popping percentage even in the range of moisture of 9% to 13% w.b.

4. Conclusions

The study found that each cultivar presents a unique combination of optimum microwave power and time settings for achieving higher popping percentages. Both microwave power and process time affected significantly to popping percentage for each cultivar. The theoretical models developed for each cultivar consisted of quadratic equations with two-way interaction effects, based on the regression coefficients obtained from the statistical analysis. This allows to obtaing the optimum parameters for each ñuña cultivar, obtaining almost 100% of popping percentage for Vaquita poroto, Negra and Jabona cultivars.

Regarding effect of moisture content, this work found that moisture effect of ñuña grains affected the popping percentage and expansion percen-tage. Indeed, a range from 9% w.b. to 11% w.b. of moisture were the best for popping process. In contrast, the popping percentage drastically decay when moisture reaches 15%. On the other hand, popping expansion tended to increase with moisture content increment.

After the two stage of this study, Vaquita poroto cultivar is recommended since it presented the highest popping percentage even at a range of moisture from 9% to 13% w.b. In addition, more researches which study storage conditions of beans on popping yield should be performed since composition changes during time despite the moiture is mainteined (grains hardening).

Author Contribution

J. Saavedra: Formal Analysis, Investigation, Methodology, Validation, Writing – original draft, Writing – review & editing, Conceptualization. A. C. Miano: Investigation, Methodology, Project administration Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing, Conceptualization.

Conflict of Interest Statement

Authors have no conflict of interest to declare.

ORCID

J. Saavedra https://orcid.org/0009-0006-5172-6444

A. C. Miano https://orcid.org/0000-0002-2874-3012

References

Anithasri, M., Vennila, P., & Ilamaran, M. (2018). Studies on Screening of Sorghum Varieties for Popping. Madras Agricultural Journal, 105. https://doi.org/10.29321/MAJ.2018.000138

Anne Allred-Coyle, R. B. T., Wendy Reiboldt, Mani Thakur, Tracey. (2000). Effects of moisture content, hybrid variety, kernel size, and microwave wattage on the expansion volume of microwave popcorn. International Journal of Food Sciences and Nutrition, 51(5), 389-394. https://doi.org/ 10.1080/096374800426984

Castro-Giráldez, M., Fito, P., Prieto, J., Andrés, A., & Fito, P. (2012). Study of the puffing process of amaranth seeds by dielectric spectroscopy. Journal of food engineering, 110(2), 298-304. https://doi.org/10.1016/j.jfoodeng.2011.04.012

Cruz Balarezo, J., Camarena Mayta, F., Baudoin, J. P., Huaringa Joaquín, A., & Blas Sevillano, R. (2009). Evaluación agromorfológica y caracterización molecular de la ñuña (Phaseolus vulgaris L.). Idesia (Arica), 27(1), 29-40. http://dx.doi.org/10.4067/S0718-34292009000100005

de la O-Olán, M., Santacruz-Varela, A., Sangerman-Jarquín, D. M., Gámez-Vázquez, A. J., Arellano-Vázquez, J. L., Valadez-Bustos, M. G., & Perches, M. A. A. (2018). Estandarización del método de reventado para la evaluación experimental del maíz palomero. Revista Mexicana de Ciencias Agrícolas, 9(7), 1471-1471. https://doi.org/10.29312/remexca.v9i7.1675

Devi, M. K., & Das, S. K. (2018). Microwave popping characteristics of paddy as affected by sample placement and geometry and process optimization. Journal of food engineering, 221, 45-53. https://doi.org/10.1016/j.jfoodeng.2017.09.026

Ernoult, V., Moraru, C., & Kokini, J. (2002). Influence of fat on expansion of glassy amylopectin extrudates by microwave heating. Cereal Chemistry, 79(2), 265-273. https://doi.org/10.1094/CCHEM.2002.79.2.265

ERTAŞ, N., Soylu, S., & Bilgicli, N. (2009). Effects of kernel properties and popping methods on popcorn quality of different corn cultivars. Journal of food process engineering, 32(4), 478-496. https://doi.org/10.1111/j.1745-4530.2007.00228.x

Gökmen, S. (2004). Effects of moisture content and popping method on popping characteristics of popcorn. Journal of Food Engineering, 65(3), 357-362. https://doi.org/10.1016/j.jfoodeng.2004.01.034

Hoseney, R., Zeleznak, K., & Abdelrahman, A. (1983). Mechanism of popcorn popping. Journal of cereal Science, 1(1), 43-52.

Kumari, R., Singh, K., Jha, S., Singh, R., Sarkar, S. K., & Bhatia, N. (2018). Nutritional composition and popping characteristics of some selected varieties of pearl millet (Pennisetum glaucum).

Llopart, E. E., & Drago, S. R. (2016). Physicochemical properties of sorghum and technological aptitude for popping. Nutritional changes after popping. LWT-Food Science and Technology, 71, 316-322. https://doi.org/10.1016/j.lwt.2016.04.006

Maisont, S., & Narkrugsa, W. (2010). Effects of salt, moisture content and microwave power on puffing qualities of puffed rice. Agriculture and Natural Resources, 44(2), 251-261.

Marrelli, M., Statti, G., & Conforti, F. (2020). A review of biologically active natural products from Mediterranean wild edible plants: Benefits in the treatment of obesity and its related disorders. Molecules, 25(3), 649. https://doi.org/10.3390/molecules25030649

Metzger, D., Hsu, K., Ziegler, K., & Bern, C. (1989). Effect of moisture content on popcorn popping volume for oil and hot-air popping. Cereal chemistry (USA).

Miano, A. C., & Augusto, P. E. D. (2015). From the sigmoidal to the downward concave shape behavior during the hydration of grains: Effect of the initial moisture content on Adzuki beans (Vigna angularis). Food and bioproducts processing, 96, 43-51. https://doi.org/http://dx.doi.org/10.1016/j.fbp.2015.06.007

Mir, S. A., Bosco, S. J. D., Shah, M. A., Mir, M. M., & Sunooj, K. V. (2016). Process optimization and characterization of popped Brown Rice. International Journal of Food Properties, 19(9), 2102-2112. https://doi.org/10.1080/10942912.2015.1105254

Mishra, G., Joshi, D., & Panda, B. K. (2014). Popping and puffing of cereal grains: a review. Journal of grain processing and storage, 1(2), 34-46.

Otálora, J. M., Ligarreto, G. A., & Romero, A. (2006). Comportamiento de fríjol común (Phaseolus vulgaris L.) tipo reventón por características agronómicas y de calidad de grano. Agronomía Colombiana, 24(1), 7-16.

Pastor, S., Fuentealba, B., & Ruiz, M. (2006). Cultivos subutilizados en el Perú: análisis de las políticas públicas relativas a su conservación y uso sostenible.

Pohndorf, R. S., Lang, G. H., Ferreira, C. D., Ziegler, V., Goebel, J. T., & de Oliveira, M. (2019). Kinetic evaluation and optimization of red popcorn grain drying: Influence of the temperature and air velocity on the expansion properties and β‐carotene content. Journal of Food Process Engineering, 42(6), e13204. https://doi.org/10.1111/jfpe.13204

Puangjinda, K., Matan, N., & Nisoa, M. (2016). Effects atmospheric radio-frequency plasma treatment on popping characteristics of popped rice and its nutritional evaluation. Innovative food science & emerging technologies, 35, 119-124. https://doi.org/10.1016/j.ifset.2016.04.010

Pugh, N., Awika, J. M., & Rooney, W. L. (2017). Heritability of popping characteristics in sorghum grain. Crop Science, 57(1), 71-77. https://doi.org/10.2135/cropsci2016.04.0250

Rezaey, M., Heitholt, J., Miles, C., & Ganjyal, G. M. (2024). Physicochemical characteristics and popping efficiencies of popping beans from different breeding programs and grow-out locations. Cereal chemistry, 101(1), 166-178. https://doi.org/https://doi.org/10.1002/cche.10733

Sanchez-Pardo, M. E., Ortiz-Moreno, A., García-Zaragoza, F., Necoechea-Mondragón, H., & Chanona-Perez, J. J. (2012). Comparison of pound cake baked in a two cycle microwave-toaster oven and in conventional oven. LWT-Food Science and Technology, 46(1), 356-362. https://doi.org/10.1016/j.lwt.2011.08.013

Shimoni, E., Dirks, E., & Labuza, T. (2002). The relation between final popped volume of popcorn and thermal–physical parameters. LWT-Food Science and Technology, 35(1), 93-98. https://doi.org/10.1006/fstl.2001.0823

Solanki, C., Mridula, D., & Nanda, K. (2018). Microwave vs conventional popping system: A comparative evaluation for maize popping. IJCS, 6(6), 176-181.

Spaeth, S. C., Debouck, D. G., Tohme, J., & Beem, J. v. (1989). Microstructure of nuñas: Andean popping beans (Phaseolus vulgaris L.). Food Structure, 8(2), 13.

Srdić, J., Milašinović-Šeremešić, M., Radosavljević, M., Kravić, N., & Babić, V. (2017). Evaluation of agronomic and sensory characteristics of the popcorn kernel. Journal on Processing and Energy in Agriculture, 21(4), 185-187. https://doi.org/10.5937/JPEA1704185S

Srdić, J., Pajić, Z., Filipović, M., & Sečanski, M. (2015). The influence of moisture content of grain on popping volume of popcorn hybrids (Zea mays l. everta). Journal on Processing and Energy in Agriculture, 19(1), 24-26.

Srdić, J., Perić, V., Kolarić, L., Kravić, N., Babić, V., & Simić, M. (2018). The influence of moisture content on popping traits in popcorn. Journal on Processing and Energy in Agriculture, 22(4), 184-187.

Stewart, F. C. (1923). Relation of moisture content and certain other factors to the popping of popcorn.

Swarnakar, A. K., Devi, M. K., & Das, S. (2014). Popping characteristics of paddy using microwave energy and optimization of process parameters. International Journal of Food Studies, 3(1). https://doi.org/10.7455/ijfs/3.1.2014.a4

Swarnakar, A. K., Mohapatra, M., & Das, S. K. (2022). A review on processes, mechanisms, and quality influencing parameters for puffing and popping of grains. Journal of Food Processing and Preservation, 46(10), e16891. https://doi.org/https://doi.org/10.1111/jfpp.16891

Swarnakar, A. K., Srivastav, P. P., & Das, S. K. (2020). Optimization of pressure parboiling conditions and pre-conditioned moisture content of brown rice (unpolished rice) for microwave puffing and its comparison with hot sand bed puffing. International Journal of Food Studies, 9. https://doi.org/10.7455/ijfs/9.SI.2020.a1

Valladolid Chiroque, A. R. (2016). Leguminosas de Grano: Cultivares y Clases Comerciales del Perú. Lima, Perú: Heinz Plenge Pardo

van Beem, J., & Spaeth, S. C. (1990). Popping in Nuña Beans (Phaseolus vulgaris, Fabaceae) Grown outside of Traditional Areas. Economic Botany, 133-135.

Van der Sman, R., & Bows, J. (2017). Critical factors in microwave expansion of starchy snacks. Journal of Food Engineering, 211, 69-84. https://doi.org/10.1016/j.jfoodeng.2017.05.001

Vázquez, C., Ortega, C., Guerrero, H., & Coutiño, E. (2011). Evaluación bioquímica e industrial de razas nativas de maíz de la región serrana de Sonora. Amplitud, mejoramiento, usos y riesgos de la diversidad genética de maíz en México. Sociedad Mexicana de Fitogenética, AC. Chapingo, Estado de México, 97-142.

Vorwald, J., & Nienhuis, J. (2009a). Effects of seed moisture content, cooking time, and chamber temperature on nuña bean (Phaseolus vulgaris L.) popping. HortScience, 44(1), 135-137. https://doi.org/10.21273/HORTSCI.44.1.135

Vorwald, J., & Nienhuis, J. (2009b). Heritability and correlations among popping characteristics and seed weight in a broad-based temperate-adapted nuña bean (Phaseolus Vulgaris L.) population. Hortscience, 44(1), 214-216. https://doi.org/10.21273/HORTSCI.44.1.214

Ziegler, K. E. (2000). Popcorn. In Specialty corns (pp. 211-246). CRC Press.

(g) is the mass of water that have to be added to reach the desired moisture content,

is the initial moisture content of grains (% w.b.) and

is the desired moisture content that grains should reach.

(Equation 1)

(Equation 2)

(g) is the mass that grains must reach to reduce their moisture content to

.

(Equation 3)

(Equation 4)

(Equation 5)