Effect and viability of Guadua angustifolia Kunth biochar on soil conditions and the development of Zea mays L.

Efecto y viabilidad del biochar de Guadua angustifolia Kunth en las condiciones del suelo y el desarrollo de Zea mays L.

Andres David Vargas Guzman1 *; Oscar Eduardo Valbuena Calderon1;

Carlos Andres Moreno Salguero1

1 Escuela de Ciencias Agrícolas Pecuarias y del Medio Ambiente, Universidad Nacional Abierta y a Distancia, Calle 14 Sur # 14 – 23 Barrio Restrepo, Bogotá, Colombia.

ORCID de los autores

A. D. Vargas Guzman: https://orcid.org/0000-0003-3371-0853 O. E. Valbuena Calderon: https://orcid.org/0000-0001-9149-156X

C. A. Moreno Salguero: https://orcid.org/0000-0002-5326-0995

RESUMEN

La demanda mundial de alimentos ha generado un aumento en el uso de los fertilizantes, los cuales tienen impactos ambientales negativos en el suelo, el agua y el aire. En este contexto se propone el biochar como una alternativa sostenible para mejorar la salud del suelo disminuyendo la dependencia de insumos agrícolas. Este estudio evaluó la viabilidad ambiental, productiva y económica del biochar elaborado con Guadua angustifolia Kunth en plantas de Zea mays L. en el municipio de Pitalito, Huila, Colombia. Aplicando cinco tratamientos: T1 (fertilización sintética convencional), T2 y T3 (fertilización sintética con 80 y 160 g de biochar), T4 y T5 (80 y 160 g de biochar), se utilizó un diseño completamente aleatorio con tres réplicas. Los resultados mostraron que T2 (5 t/ha de biochar) presentó un aumento del 10% en biomasa aérea comparado con T1, mejoró parámetros del suelo como el pH, la capacidad de intercambio catiónico y redujo del aluminio intercambiable (~63%). El biochar logró una captura de carbono de 2 135 a 2 155 kg CO₂eq/t, con posibilidad de generar certificados de captura (CORCs). El costo de producción por tonelada estimado fue USD 303, el costo total de aplicación por hectárea estimado fue USD 1 816 con la dosis de 5t/ha.

Palabras clave: Agricultura sostenible; Enmiendas para suelos; Fertilización balanceada.

ABSTRACT

Global demand for food has led to an increase in the use of fertilisers, which have negative environmental impacts on soil, water and air. In this context, biochar is proposed as a sustainable alternative to improve soil health and reduce dependence on agricultural inputs. This study evaluated the environmental, productive, and economic viability of biochar made from Guadua angustifolia Kunth in Zea mays L. plants in Pitalito, Huila (Colombia). Five treatments were applied: T1 (conventional synthetic fertilisation), T2 and T3 (synthetic fertilisation with 80 and 160 g of biochar per plant), T4 and T5 (80 and 160 g of biochar per plant), using a completely randomised design and three replicates. The results showed that T2 (equivalent to 5 t/ha of biochar) presented a ~10% increase in above-ground biomass compared to T1, improved soil parameters such as pH, cation exchange capacity and reduction of exchangeable aluminium (~63%). Biochar also showed a carbon capture potential of 2 135–2 155 kg CO₂eq/t, with the possibility of generating removal certificates (CORCs). The production cost per tonne was estimated at USD 303, and total application cost per hectare was estimated at USD 1 816 at a dose of 5 t/ha.

Keywords: Sustainable agriculture; Soil amendment; Balanced fertilisation.

1. Introduction

The excessive application of fertilisers to the soil is a current problem that causes serious environmental impacts such as acidification and degradation of soil properties, leaching of nutrients into water bodies, and an increase in greenhouse gases in the atmosphere. The use of fertilisers is justified by the growing global demand for food, which is why there is a need to identify and evaluate sustainable alternatives that increase the efficiency of these inputs.

Biochar is becoming an alternative solution to this problem, as it is an organic soil amendment produced by mixing charcoal with nutrients and microorganisms. Several studies have been conducted to evaluate its properties and demonstrate its environmental, economic, and productive benefits for crops. One raw material that can be used to produce high-quality biochar is Guadua angustifolia Kunth (Orozco-Gutiérrez and de Lira-Fuentes, 2020), which has high biomass generation, a high lignocellulosic content and a porous cell structure that gives biochar larger specific surface area and water retention capacity compared to other lignocellulosic raw materials such as pine (Masís-Meléndez et al. 2020).

The high temperature of pyrolysis makes biochar alkaline, Hossain et al. (2020) show that this is due to the large number of alkalis and alkaline metals that are not volatilised, allowing biochar to have a pH close to 10, and found that applying doses of 50 and 100 t/ha to soils with a pH of 5.25 can generate an increase of up to 4.5 units. Biochar also stabilizes the pH of soil, Jiang et al. (2025), found that the application of biochar increases the soil's acid buffering capacity, preventing the application of fertilisers such as urea from lowering the pH again. Biochar also helps prevent soil degradation by reducing the amount of fertiliser needed to obtain the same yield. Saharudin et al. (2024) analysed multiple studies and found that for various crops, biochar allows for a consistent reduction of 10% in nitrogen (CO(NH2)2) application, a 5% reduction in phosphorus (P2O5) application, and a 5% reduction in potassium (K2O) application.

The decrease in the inputs required for crops is also due to the reduction in the risk of nutrient leaching and their physical and chemical fixation on the surface of the biochar, as well as positive impacts on the rhizosphere microbiota (Ayaz et al. 2021, Jiang et al. 2025). The literature indicates that, by reducing the use of fertilisers, biochar generates a reduction in crop production costs. In response to this, authors such as Patel and Panwar (2024) emphasise that the economic benefits of biochar should be quantified in the medium to long term, a statement supported by Latawiec et al. (2021), who find profitability within three to four years with doses of 40, 60, and 80 t/ha.

Based on the above context, the potential of G. angustifolia biochar as an amendment capable of positively impacting soil properties and crop yields is evident, generating economic and environmental benefits by reducing the need for synthetic chemical fertilisers and capturing carbon in the long term. However, despite this information, there is a knowledge gap, as there are no studies evaluating the feasibility of applying G. angustifolia biochar in Colombia, including its environmental, economic, and productive aspects together.

2. Methodology

2.1 Type of study and methodological approach

The experiment was conducted using a quanti-tative experimental approach, employing a completely randomised design (CRD). Agronomic variables were measured for Z. mays plants (above-ground and root biomass accumulation, foliar analysis) and edaphic variables (through soil analysis). In addition, variables related to the economic aspects of biochar production were measured, from the crop of G. angustifolia to the final application of biochar.

2.2 Location and site conditions

The experiment was carried out at El Vergel farm, located in the Honda Porvenir district of the municipality of Pitalito, Huila (Colombia). The area is situated at an altitude of 1 288 metres above sea level, with geographical coordinates 1°49'11.67 N and 76°2'53.18"W. With average temperatures of 17 °C to 25 °C, the area used for the study was a 200 m2 plot with flat topography and no shade.

2.3 Preparation of biochar

The biochar was produced by pyrolysis of G. angustifolia, harvested at maturity, three to four years old. The culms were dried naturally for one month, and the final moisture content of the biomass was measured with a hygrometer, with an average result of less than 20%. The material was subjected to pyrolysis at a temperature of 500°C for a period of four hours in a retort-type kiln with a capacity for 250 kg of biomass. The charcoal obtained was ground using a hammer mill and mixed with composted chicken manure (detailed in Table 1) in a 1:1 ratio, 300 mL of water was added for each kg of the mixture, which was left to ferment for 15 days. The temperature and humidity of the mixture were monitored daily to ensure that it did not exceed 70°C, aiming to prevent the death of microorganisms and increasing nutrient mineralisation.

2.4 Experimental design and treatments

Following the methodology proposed by Cargua Chávez (2020), four treatments and one control were established, each with three replicates. These were randomly distributed in an area of 200 m2 in plastic bags containing 10 kg of substrate, which had been previously characterised (Table 1). Two seeds of Z. mays, variety ICA V-305, were sown in each bag. The treatments applied were: T1: Synthetic fertiliser NPK (15g) (Control); T2: fertiliser NPK (15g) + biochar (80g); T3: fertiliser NPK (15g) + biochar (160g); T4: biochar (80g); T5: biochar (160g).

The fertiliser used was a commercial mixture (Nutrimon®, Monómeros, Colombia) of N-P-K (15-15-15), which was applied in two stages: five grams on the fifth day after the emergence of the coleoptile and an additional 10 grams 15 days later, while the biochar was mixed with the substrate before bagging. 46 days after coleoptile emergence, data were collected on above-ground biomass and root biomass, and a foliar nutrient analysis and a physicochemical soil analysis were performed.

2.5 Statistical Analysis

An analysis of variance (ANOVA) and Tukey's multiple comparison test were performed for each of the variables in the previous section, with a significance level (P < 0.05). Analysis software Real Statistics (V2) and R (V 4.4.1) were used.

3. Results and discussion

The initial soil characterisation shows a sandy loam texture with a pH of 4.03 and a high content of exchangeable aluminium. There is a low percentage of nitrogen and organic matter and medium to high concentrations of phosphorus, potassium, magnesium, calcium, sodium, iron and sulphur. On the other hand, there is evidence of low concentrations of boron, copper, manganese and zinc (Table 1).

Based on the data, it is interpreted that the soil has good aeration and drainage, but low water and nutrient retention capacity (Abiala and Blackwood, 2024). The pH is very low and may limit the availability of nutrients such as calcium, magnesium, and phosphorus. In addition, the acidity causes a high content of exchangeable aluminium, which is phytotoxic and negatively impacts root and plant growth (Chen et al. 2023).

Also, it is evident that there is low biological fertility due to low levels of nitrogen and organic matter, which can affect plant development and soil microbiota. This is compounded by low levels of boron, copper, manganese, and zinc, which have an impact on enzyme activity in plants (Gerke, 2022).

Table 1

Characterisation of initial conditions of the materials used in the experiment

Variable | Result |

Soil | Chicken manure | Biochar |

pH (units) | 4.03 | 7.6 | 9.53 |

Conductivity (µs/cm) | 66.90 | 332 | 46.19 |

C.E.C (meq/100g) | 34.40 | 41.5 | 40.18 |

Organic nitrogen (%) | 0.08 | 1.60 | 0.32 |

Organic matter (%) | 2.49 | - | 18.04 |

Available phosphorus (ppm) | 18.03 | 3.60 | 2 740.68 |

Potassium (ppm) | 0.52 | 2 800 | 19.06 |

Magnesium (meq/100g) | 4.23 | 1.09 | 24.26 |

Calcium (meq/100g) | 10.73 | 162 | 33.79 |

Exchangeable aluminium (meq/100g) | 1.62 | - | 0 |

Sodium (meq/100g) | 0.18 | 15.49 | 6.06 |

Iron (ppm) | 77.32 | 4 010 | 75.48 |

Boron (ppm) | 0.17 | 35.6 | 31.94 |

Copper (ppm) | 0.81 | 53.2 | 34.84 |

Manganese (ppm) | 10.52 | 412 | 18.58 |

Zinc (ppm) | 1.13 | 366 | 32.98 |

Sulphur (ppm) | 17.05 | 4 220 | 6.16 |

On the other hand, the characterisation of biochar (Table 1) shows a high pH (9.63), which is suitable for reducing soil acidity. It also has low electrical conductivity, indicating that there is no risk of soil salinisation. Furthermore, its high cation exchange capacity can help in the retention and release of nutrients to plants.

3.1 Changes in soil health

The analysis of variance shows that there were no significant changes (p > 0.05) in the granulometric variables, percentage of sand, silt and clay (Table 2). This result is consistent with that reported by Toková et al. (2020) and Li et al. (2021), who found that physical changes in the soil are only evident at high doses above 20 t/ha, whereas in this experiment a maximum dose of 10 t/ha was used.

Significant differences (p < 0.05) were identified in all treatments regarding the pH variable, where the treatments with biochar recorded a higher pH (Table 2). Hossain et al. (2020) and Jiang et al. (2025) explain that biochar displaces acid cations in the soil and reduces the risk of cationic base leaching, which adds to the presence of functional groups with oxygen and other organic anions that, through protonation and deprotonation reactions, allow the anchoring of iron oxides and hydroxides, increasing the soil's acidity buffering capacity and helping to prevent pH from decreasing when nitrogen fertilisers are applied.

Authors such as Hossain et al. (2020) report that an increase in pH leads to a decrease in phytotoxicity caused by exchangeable aluminium in acidic soils, which was reduced by 64.17% (95% CI; 60.00% - 66.11%; p < 0.05) in the treatments with biochar (T2 to T5) compared to the treatment without biochar (T1) (Table 2).

Electrical conductivity also showed significant differences (p < 0.05) between all treatments, with T1, T3, and T5 showing the highest conductivity, which may indicate that the ionic salt content decreases when biochar is applied in low quantities (Abiala & Blackwood, 2024).

In terms of cation exchange capacity, the highest values were found in the treatments with the highest dose of biochar. This is similar to the results of Chen et al. (2020) who found an increase in cation exchange capacity in two soil types when applying four different doses of biochar, showing a significant increase p < 0.05) between treatments, with the highest doses of biochar presenting a higher cation exchange capacity. In contrast, studies such as those by Li et al. (2021) report that biochar had no impact on this parameter, so it can be inferred that this effect does not always occur.

Regarding the major elements in the soil, there is no significant difference (p > 0.05) in nitrogen concentration, considering that it is an element that volatilises during biomass pyrolysis in the form of ammonia (Rathyanake et al. 2023). For potassium, there are significant differences between treatments, with the highest concentrations found in those with the highest doses of biochar. These results are consistent with those reported by Rathyanake et al. (2023). For phosphorus, the authors indicate that it accumulates in biochar at pyrolysis temperatures above 650 °C. A lower concentration is evident in the biochar treatments (T2 to T5) compared to the control (T1), which may indicate that there was greater bioavailability of the element when biochar was applied.

For minor elements, the analysis of variance shows that there is no significant difference in the concentration of sodium, iron, copper, manga-nese, and zinc. On the other hand, there were significant differences in the content of mag-nesium, calcium, boron, and sulphur (Table 2).

Table 2

Soil analysis results 46 days after coleoptile emergence in Z. mays cultivation

Treatment | pH | Conductivity (µs/ cm) | CEC (meq/100g) | Exchangeable Al (meq/100g) | K (meq/100g) |

Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE |

T1 | 4.51a ± 0.00 | 94.22a ± 0.00 | 18.68a ± 0.02 | 1.80a ± 0.00 | 0.70a ± 0.02 |

T2 | 4.74b ± 0.00 | 68.93b ± 0.00 | 20.36b ± 0.01 | 0.65b ± 0.01 | 0.91b ± 0.02 |

T3 | 5.09c ± 0.00 | 81.90c ± 0.01 | 23.07c ± 0.05 | 0.61b ± 0.00 | 1.12c ± 0.02 |

T4 | 5.02d ± 0.00 | 46.83d ± 0.00 | 18.28a ± 0.39 | 0.68b ± 0.01 | 0.70a ± 0.02 |

T5 | 5.30e ± 0.00 | 71.58e ± 0.03 | 23.92c ± 0.05 | 0.62b ± 0.00 | 1.51d ± 0.02 |

p-value ANOVA | < 0.05 | < 0.05 | < 0.05 | < 0.05 | < 0.05 |

Treatment | Mg (meq/100g) | Ca (meq/100g) | P (ppm) | B (ppm) | S (ppm) |

Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE |

T1 | 2.56a ± 0.01 | 6.1a ± 0.05 | 99.08a ± 0.1 | 0.56a ± 0.11 | 15.94a ± 0.16 |

T2 | 2.96b ± 0.01 | 6.97b ± 0.01 | 62.08b ± 0.08 | 0.61a ± 0.06 | 7.76b ± 0.19 |

T3 | 3.61c ± 0.01 | 7.86c ± 0.03 | 64.42c ± 0.05 | 0.53a ± 0.01 | 13.35c ± 0.16 |

T4 | 2.24d ± 0.01 | 6.95b ± 0.01 | 43.75d ± 0.05 | 0.49ab ± 0.00 | 10.62d ± 0.18 |

T5 | 2.54a ± 0.00 | 7.71c ± 0.01 | 45.85e ± 0.1 | 0.17b ± 0.00 | 18.90e ± 0.16 |

p-value ANOVA | < 0.05 | < 0.05 | < 0.05 | < 0.05 | < 0.05 |

Different letters in each column indicate significant differences between treatments (p < 0.05; Tukey's test).

In terms of calcium content, T1 had the lowest concentration, the treatments with the lowest dose of biochar (T2 and T4) had intermediate concentrations, and the treatments with the highest dose (T3 and T5) had the highest concentrations. For magnesium, T3 had the highest content, while for boron there was no significant difference between treatments, except for T5, which had a lower concentration. Finally, in relation to sulphur content, all treatments were statistically different, and T5 had the highest content (Table 2).

3.2 Carbon capture measurement

The carbon capture calculation was performed using the methodology proposed by Puro.earth (2025) which has been used by authors such as Fawzy et al. (2022).

The amount of carbon permanently fixed in the soil is calculated based on a minimum projection of 200 years, which is determined using the equation (1) proposed by Puro.earth (2025):

PF=M-A(H/Corg) (1)

Where PF is the persistence factor of carbon present in biochar, M and A are regression parameters to include the effect of soil temperature, which are reported by Puro.earth. For a soil temperature of 17 °C, M = 90.96 and A = 31.39 were found. H is the hydrogen content of biochar, which was found in the studies by Césare et al. (2019) and Ardila et al. (2019) to be 5.96% and 6.7%, respectively. Finally, Corg is the percentage of organic carbon in G. angustifolia biochar, which was taken from the study by Cañon-Tafur et al. (2025), who reported a value of 46.323% ± 1.513.

Using the above data, a PF = 86.27% to 87.05% was calculated. This result is higher than that reported by Fawzy et al. (2022), who found values ranging from 59.82% to 81.52% for oil palm biochar. However, percentages ranging from 80% to 87% were reported for other raw materials (Ayaz et al. 2021; Saharudin et al. 2023).

To calculate the amount in kg CO2 equivalent captured per tonne of biochar applied to the soil, the Puro.earth methodology was followed, applying the equation (2):

Closs=Cstored(100-PF) (2)

Where Closs is the amount of carbon released back into the atmosphere and Cstored is the gross amount of carbon captured by biochar, which was taken from the analysis reported by Cañon-Tafur et al. (2025) and quantified at 66.92%. For one tonne of biochar, Cstored = 2 475.04 kg CO2eq and Closs = 320.67 – 340.05 kg CO2eq, resulting in a carbon capture amount of 2 135.99 to 2 155.37 kg CO2eq per tonne of G. angustifolia biochar applied to the soil. This value is like that reported by other authors such as Yin et al. (2022), who calculated a range of 2 408–2 682 kg CO2eq/t, Saharudin et al. (2024), with values of 2 063 to 3 900 kg CO2eq/t, and Fan et al. (2021), who found 900 to 6 600 kg CO2eq/t. The results obtained show a high carbon capture potential in G. angustifolia biochar.

3.3 Changes in plant growth

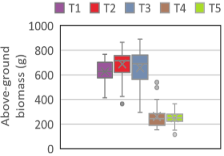

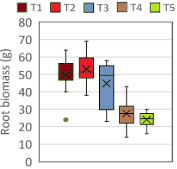

Analysis of the results for above-ground biomass accumulation shows that there is a significant difference (p < 0.05) between treatments, with T2 showing the highest accumulation (Figure 1). On the other hand, the results for root biomass showed differences only between the group with additional fertilisation (T1 to T3) and the group to which only biochar was applied (T4 and T5) (Figure 2).

Figure 1. Above-ground of Z. mays accumulated over 46 days after coleoptile emergence.

Figure 2. Root biomass of Z. mays accumulated over 46 days after coleoptile emergence.

Regarding above-ground biomass, T2 showed the highest accumulation, being 10.05% higher (95% CI 3.60%–16.51% P < 0.05) than control (T1). This phenomenon is confirmed by authors such as Ayaz et al. (2021) and Yang et al. (2022), who indicate that the change produced by biochar in soil properties, such as increased pH and reduced exchangeable aluminium, frees up cation exchange spaces that increase the bioavailability and nutrient retention capacity of the soil. The result obtained in T3 is consistent with that reported by Yang et al. (2022), who indicate that high doses of biochar do not represent substantial improvements and that exceeding the optimal dose (5 t/ha in this case) can generate zero or adverse additional effects.

The biomass accumulation results are compared with those reported by Khan et al. (2024), who conducted a meta-analysis (114 studies) in which they identified an average increase of 20% in the yield of the crops analysed, being more pronounced in acidic soils, similar to the pH conditions in which this study was conducted. On the other hand, Ullah et al. (2024) and Jiang et al. (2024) report that the increase in crop yield remains in the range of 3% to 16% in the long term.

The results of root biomass accumulation (Figure 2) indicate that the application of biochar did not have an impact on root growth, given that there is no significant difference (p > 0.05) between treatments T1, T2, and T3, a result corroborated by authors such as González-Marquetti et al. (2020), who found that the application of biochar can inhibit root growth.

3.4 Changes in foliar nutrition

The results of the foliar analysis show that there is no significant change (p > 0.05) in the concentration of zinc, chlorine, boron, potassium, sulphur, calcium, sodium, and copper. These results are like those reported by González-Marquetti et al. (2020), who highlight the findings of various studies showing that biochar did not increase nutrient content at the leaf level but did have a positive impact on plant growth and crop yields, especially in combination with additional fertilisation. However, in the present study, significant differences (p < 0.05) were found in the contents of nitrogen, phosphorus, magnesium, iron, and manganese, as shown in Table 3.

There are no significant differences (p > 0.05) between T1, T2, and T3 for any of the variables, so it can be inferred that biochar did not have a significant impact on the foliar content of the elements analysed, which has been reported in other cases by authors such as González-Marquetti et al. (2020), who found that biochar has an indeterminate impact on foliar nutrition when analysing various studies.

Furthermore, González-Marquetti et al. (2020) confirm the findings in treatments T4 and T5, where implementing biochar without additional fertilisation compromises productivity, resulting in low yields due to phytotoxic effects. However, Naeem et al. (2024) reported that applying doses of 5 t/ha and 10 t/ha of Acacia nilotica L. biochar without additional fertilisation resulted in a 26% increase in grain and stubble and a 29% increase in total seed weight in a maize crop.

3.5 Production and application costs of biochar

To calculate the costs of producing and applying biochar, the methodology proposed by Saharudin et al. (2024) was followed, which included the acquisition and transport of biomass to the production plant, drying and preparation of the material, the pyrolysis process, grinding, and packaging. The costs of activating the biochar by loading it with nutrients and microorganisms from chicken manure were added (Table 4). The production costs resulted in a value of USD 303 per tonne of biochar (produced and packaged).

Table 4

Production and application costs of biochar

Production costs per ton of biochar | (USD) |

Biomass acquisition and transport | 33 |

Preparation and drying | 22 |

Pyrolysis and milling | 88 |

Activation of biochar | 149 |

Packaging | 11 |

Total | 303 |

Application costs per hectare | (USD) |

Transport | 71 |

Application | 230 |

Total | 301 |

Table 3

Characterisation of Z. mays leaves 46 days after coleoptile emergence

Treatment | Nitrogen (%) | Phosphorus (%) | Magnesium (%) | Iron (PPM) | Manganese (PPM) |

Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE |

T1 | 2.92a ± 0.05 | 0.38a ± <0.05 | 0.18a ± <0.05 | 113.0ab ± 4.54 | 59.00ab ± 2.16 |

T2 | 2.91a ± 0.12 | 0.44a ± <0.05 | 0.16ab ± <0.05 | 121.0a ± 11.14 | 67.67b ± 7.51 |

T3 | 2.15ab ± 0.28 | 0.39a ± <0.05 | 0.13ab ± <0.05 | 98.0ab ± 13.49 | 54.67ab ± 4.25 |

T4 | 1.24bc ± 0.08 | 0.26b ± <0.05 | 0.09b ± <0.05 | 64.3b ± 5.17 | 39.00b ± 1.69 |

T5 | 1.13c ± 0.11 | 0.25b ± <0.05 | 0.09b ± <0.05 | 60.0b ± 2.16 | 36.33b ± 1.18 |

Different letters in each column indicate significant differences between treatments (p < 0.05; Tukey's test).

To calculate application costs per hectare a planting density of 62 500 corn plants per hectare was considered, applying 80 g dose per plant (which yielded the best results), the necessary amount of biochar per hectare is calculated to be five tonnes, which costs USD 1515 (using the calculated value of USD 303 per tonne) and adding the costs associated with transport and application, which were calculated at USD 301 per hectare (Table 4), the total cost of biochar production and application for the year 2025 is estimated at USD 1 816 per hectare.

The final application value far exceeds the estimated cost of conventional chemical fertilisation for Z. mays crop in Colombia, which was calculated at USD 566 per hectare in 2025. According to Liu et al. (2025), the application of biochar should be considered a medium- and long-term investment, as the benefits of biochar remain in the soil for up to 12 years after application, thereby increasing profitability. Similarly, Zhang et al. (2023) have documented a reduction of up to 40% in the need for synthetic chemical fertilisers over several harvests, which increases economic security in an environment where there is high price volatility.

According to Patel & Panwar (2024) and Latawiec et al. (2021), returns increase over time, especially with moderate doses (< 10 t/ha), which maximises the net present value of the investment and the internal rate of return.

3.6 Economic benefits of biochar

Given the economic benefits that can be obtained from the application of biochar, Saharudin et al. (2024) consider the reduction in the quantity of fertilizers required for crops (up to 40% less) and the possible sale of CO2 removal certificates (CORCs), which can generate significant additio-nal income for farmers. Fawzy et al. (2024) propose the calculation based on the following equation (3):

CORC=Estored-Ebiomass-Eproduction-Euse (3)

Where Ebiomass considers the emissions generated by the acquisition of raw materials, which were measured in the field, Eproduction considers the emissions generated by the conversion of biomass, which were calculated using mass and energy balances, taking into account that the yield of the pyrolysis process was 25% at a temperature of 500°C, which is very similar to the 27% yield at 550°C obtained by Orozco-Gutiérrez and de Lira-Fuentes (2020) during the production of biochar from G. angustifolia. Euse refers to the emissions associated with the transport and application of biochar, which were calculated using the methodology of Sahoo et al. (2021) methodology, considering less than 100 km from the G. angustifolia crop to the processing plant and the final application point. The result is 0.589–0.623 CO2 CORCs per tonne of G. angustifolia biochar applied.

The experimental results suggest that the application of G. angustifolia biochar is viable from an environmental perspective, thanks to its carbon capture capacity and its properties in improving the physicochemical conditions of acidic soils. In terms of plant growth, an increase in accumulated above-ground biomass was observed during the early growth stage. Finally, it was noted that the low production costs and economic benefits from carbon capture certificates make this amendment a sustainable alternative for agriculture in areas where G. angustifolia is available.

4. Conclusions

The application of 5t/ha of G. angustifolia biochar to Z. mays crops together with NPK fertilisation (T2) showed superior or similar properties compared to the conventional fertiliser treatment (T1) and the other biochar treatments. Biochar also showed a high carbon capture capacity, which opens the possibility for further studies applying this amount under commercial-scale field conditions and bringing the crop to harvest to determine yield. Applying biochar is a high investment but the selling of CORCs and reduction of fertiliser need over the years can minimize or negate this cost.

Acknowledgments

We would like to thank the Universidad Nacional Abierta y a Distancia for funding this project under project code PGI6602ECAPMA2024, which belongs to the project bank of Convocatoria Interna No. 12, Cohorte 2 of 2023.

References

Abiala M., & Blackwood C. (2024). Influence of soil physical properties, chemical contents and rhizobacterial loads on soil quality in maize fields of Southwestern Nigeria. African Journal of Biotechnology, 23(7), 232–244. https://doi.org/10.5897/AJB2022.17533

Ardila C. R., Folgueras M. B., & Fernández F. J. (2019). Oxidative pyrolysis of Guadua angustifolia Kunth. Energy Reports. https://doi.org/10.1016/j.egyr.2019.09.057

Ayaz M., Feizienė D., Tilvikienė V., Akhtar K., Stulpinaitė U., & Iqbal R. (2021). Biochar role in the sustainability of agriculture and environment. Sustainability, 13(3), 1330. https://doi.org/10.3390/su13031330

Cañon-Tafur L. A., Mateus-Maldonado J. F., Lozano-Puentes H. S., Herrera-Acosta C. D., Sánchez-Matiz J. J., Díaz-Ariza L. A., Costa G. M., Jiménez-Borrego L. C., Carrascal-Camacho A. K., & Pedroza-Rodríguez A. M. (2025). Guadua angustifolia biochar/TiO₂ composite and biochar as bio-based materials with environmental and agricultural application. Scientific Reports, 15, Article 246. https://doi.org/10.1038/s41598-024-81761-9

Cargua Chávez J. E., Echeverria Arangundi C. M., & Cedeño García G. A. (2020). Efectividad de biochar y biofertilizantes en el crecimiento y calidad de plántulas de cacao. ESPAMCIENCIA, 11(2), 95–100. https://doi.org/10.51260/revista_espamciencia.v11i2.224

Césare M. F., Hilario F., Callupe N., Cruz L., & Calle J. L. (2019). Caracterización química y física del bambú (Guadua angustifolia Kunth). Avances en Ciencias e Ingeniería, 10(4), 1–13.

Chen L., Liu M., Ali A., Zhou Q., Zhan S., Chen Y., Pan X., & Zeng Y. (2020). Effects of biochar on paddy soil fertility under different water management modes. Journal of Soil Science and Plant Nutrition, 20(4), 1810–1818. https://doi.org/10.1007/s42729-020-00252-8

Fan Y. V., Klemeš J. J., & Lee C. T. (2021). Environmental performance and techno-economic feasibility of different biochar applications: An overview. Chemical Engineering Transactions, 83, 469–474. https://doi.org/10.3303/CET2183079

Fawzy S., Osman A. I., Mehta N., Moran D., Al-Muhtaseb A. H., & Rooney D. W. (2022). Atmospheric carbon removal via industrial biochar systems: A techno-economic-environmental study. Journal of Cleaner Production, 371, 133660. https://doi.org/10.1016/j.jclepro.2022.133660

Gerke J. (2022). The central role of soil organic matter in soil fertility and carbon storage. Soil Systems, 6(2), 33. https://doi.org/10.3390/soilsystems6020033

González-Marquetti I., Rodríguez M. G., Delgado-Oramas B. P., & Schmidt H.-P. (2020). Biochar y su contribución a la nutrición, crecimiento y defensa de las plantas. Revista Protección Vegetal, 35(2), 1-17.

Hossain M. Z., Bahar M. M., Sarkar B., Donne S. W., Ok Y. S., Palansooriya K. N., Kirkham M. B., Chowdhury S., & Bolan N. (2020). Biochar and its importance on nutrient dynamics in soil and plant. Biochar, 2(4), 379–420. https://doi.org/10.1007/s42773-020-00065-z

Jiang H., Wu J., Guan J., Zhao F., Tan L., & Chen H. (2025). Biochar is an innovative strategy for reconstructing microbial communities and enhancing nutrient utilization efficiency in acidic red soils. Frontiers in Microbiology, 16, Article 1622408. https://doi.org/10.3389/fmicb.2025.1622408

Khan S., Irshad S., Mehmood K., Hasnain Z., Nawaz M., Rais A., Gul S., Wahid M. A., Hashem A., Abd_Allah E. F., & Ibrar D. (2024). Biochar production and characteristics, its impacts on soil health, crop production, and yield enhancement: A review. Plants, 13(2), 166. https://doi.org/10.3390/plants13020166

Latawiec A. E., Koryś A., Koryś K. A., Kuboń M., Sadowska U., Gliniak M., Sikora J., Drosik A., Niemiec M., Klimek-Kopyra A., Sporysz M., Usowicz B., & Medeiros B. (2021). Economic ana-lysis of biochar use in soybean production in Poland. Agronomy, 11(11), 2108. https://doi.org/10.3390/agronomy11112108

Li L., Zhang Y.-J., Novak A., Yang Y., & Wang J. (2021). Role of biochar in improving sandy soil water retention and resilience to drought. Water, 13(4), 407. https://doi.org/10.3390/w13040407

Liu Q., Wang J., Sun A., Dong E., Wang Y., Huang X., Hu H.-W., & Jiao X. (2025). Long-term low-rate biochar application enhances soil organic carbon without affecting sorghum yield in a calcaric cambisol. Agronomy, 15(4), 995. https://doi.org/10.3390/agronomy15040995

Masís-Meléndez F., Segura-Chavarría D., García-González C. A., Quesada-Kimsey J., & Villagra-Mendoza K. (2020). Variability of physical and chemical properties of TLUD stove derived biochars. Applied Sciences, 10(2), 507. https://doi.org/10.3390/app10020507

Naeem M. B., Jahan S., Rashid A., Shah A. A., Raja V., & El-Sheikh M. A. (2024). Improving maize yield and drought tolerance in field conditions through activated biochar application. Scientific Reports, 14, Article 25000. https://doi.org/10.1038/s41598-024-76082-w

Orozco Gutiérrez G., & de Lira Fuentes R. C. (2020). Elaboración de biocarbón para el aprovechamiento de residuos provenientes de las podas de bambú (Guadua angustifolia). Revista Mexicana de Agroecosistemas, 7(1), 1–9.

Patel M. R., & Panwar N. L. (2024). Evaluating the agronomic and economic viability of biochar in sustainable crop production. Biomass and Bioenergy, 188, 107328. https://doi.org/10.1016/j.biombioe.2024.107328

Puro.earth. (2025). Biochar methodology for CO₂ removal (Edition 2025, V1; aproved, pending final edition).

Rathnayake D., Schmidt H.-P., Leifeld J., Mayer J., Epper C. A., & Hagemann N. (2023). Biochar from animal manure: A critical assessment on technical feasibility, economic viability, and ecological impact. GCB Bioenergy, 15(9), 1078–1104. https://doi.org/10.1111/gcbb.13082

Saharudin D. M., Jeswani H. K., & Azapagic A. (2024). Biochar from agricultural wastes: Environmental sustainability, economic viability and the potential as a negative emissions technology in Malaysia. Science of The Total Environment, 919, 170266. https://doi.org/10.1016/j.scitotenv.2024.170266

Sahoo K., Upadhyay A., Runge T., Bergman R., Puettmann M., & Bilek E. (2021). Life-cycle assessment and techno-economic analysis of biochar produced from forest residues using portable systems. The International Journal of Life Cycle Assessment, 26(1), 189–213. https://doi.org/10.1007/s11367-020-01830-9

Toková L., Igaz D., Horák J., & Aydin E. (2020). Effect of biochar application and re-application on soil bulk density, porosity, saturated hydraulic conductivity, water content and soil water availability in a silty loam haplic luvisol. Agronomy, 10(7), 1005. https://doi.org/10.3390/agronomy10071005

Ullah M. S., Malekian R., Randhawa G. S., Gill Y. S., Singh S., Esau T. J., Zaman Q. U., Afzaal H., Du D. L., & Farooque A. A. (2024). The potential of biochar incorporation into agricultural soils to promote sustainable agriculture: Insights from soil health, crop productivity, greenhouse gas emission mitigation and feasibility perspectives—a critical review. Reviews in Environmental Science and Biotechnology, 23(4), 1105–1130. https://doi.org/10.1007/s11157-024-09712-4

Yang W., Feng G., Jia Y., Yang Y., Gao X., Gao L., & Qu Z. (2022). Impact of single biochar application on maize growth and water-fertilizer productivity under different irrigation regimes. Frontiers in Plant Science, 13, Article 1006827. https://doi.org/10.3389/fpls.2022.1006827

Yin J., Zhao L., Xu X., Li D., Qiu H., & Cao X. (2022). Evaluation of long-term carbon sequestration of biochar in soil with biogeochemical field model. Science of The Total Environment, 822, 153576. https://doi.org/10.1016/j.scitotenv.2022.153576

Zhang M., Liu Y., Wei Q., Liu L., Gu X., Gou J., & Wang M. (2023). Chemical fertilizer reduction combined with biochar application ameliorates the biological property and fertilizer utilization of pod pepper. Agronomy, 13(6), 1616 https://doi.org/10.3390/agronomy13061616