1. Introduction

The current trend of making bakery products added with flour from different vegetable sources as new ingredients is due to the nutritional improvements in these foods (Maietti et al., 2021; Milla et al., 2021). The use of mixed or compound flours in baking favors the partial replacement of wheat flour, this has allowed the manufacture of a several food products with better nutritional content and bioactive compounds with high antioxidant capacity, in addition these foods contribute to the development of a better quality of life in consumers, by reducing the hyperglycemic effects of bread consumption or by addressing specific problems such as wheat consumption for celiac patients (Bohl et al., 2024; Komeroski et al., 2021). Among the quality parameters in baking, analyzes of flour and dough, the baking test, the volume of the loaves and the quality of the crumb (alveoli) are carried out, the last two being most important to determine the quality of the bread given interventions such as the addition of alternative flours (Genevois & de Escalada Pla, 2021). The porosity or alveoli of the bread refer to the cavities in the bread crumb, coming from the gas bubbles that accumulate during the fermentation process carried out by the yeasts (Grenier et al., 2021). The alveolate in a bread will depend on some parameters such as the fermentation time, the cereal used, the amount of yeast, the hydration of the dough and the kneading (Curti et al., 2023; Di Renzo et al., 2024). Likewise, the addition of alternative components in the preparation of doughs can influence the alveolate and morphometry of the breads obtained during baking (Hernández-López et al., 2023). Given the constant innovation of bakery products, fast, non-invasive and cheap techniques are required to assess the quality of bread crumbs, where image analysis has been used as an objective and highly reliable method (Gonzalez Viejo et al., 2022; Olakanmi et al., 2023). This method has been used to quantify porosity, through different digital techniques, in addition, image analysis can provide quantitative information about baked goods, such as size, shape and color (Archandani et al., 2022). Therefore, the objective of this research was to evaluate the effect of the percentage substitution of papaya seed flour (HSPa) on the baking quality parameters of color and the alveolar structure in the bread crumb, through the use of the free software ImageJ, from a particle analysis as a digital tool in the development of bakery products.

2. Methodology

2.1 Obtaining papaya seed flour (Carica papaya)

The seeds were obtained from the fruit of Carica papaya, they were washed with a jet of water to eliminate the remains of mucilage and pulp. They were placed in metal trays with brown paper and covered with a sky blanket to be dried in the sun (22 ± 2 °C), once dry they were stored in Ziploc™ hermetic plastic bags. Papaya seed meal was obtained from 2.5 kg of seed on a dry basis. The seeds were ground in a ME-700Y single-phase pulverizer mill (Semillas de vida, Cuernavaca, Morelos, México). The obtained ground material was sieved through a Tyler No. 32 sieve with a pore diameter of 0.425 mm (Tyler, Monterrey, NL, Mexico). To reduce the particle size, the flour was ground two more times and sieved with a Tyler No. 60 mesh sieve with a pore diameter of 0.246 mm (Tyler, Monterrey, NL, Mexico). The flour obtained was stored in hermetic Ziploc™ plastic bags (Mérida Lira et al., 2023).

2.2 Bread making

Commercial Osasuna wheat flour (HT) from the Elizondo mills (10.38% moisture, 0.27% ash, 12.27% protein, 1.07% ether extract, 0.061% crude fiber, 75.93% carbohydrates) was used as control bread to make the breads. Replaced by HSPa (6.59% moisture, 9.18% ash, 21.61% protein, 22.22% ethereal extract, 24.46% crude fiber, 15.92% carbohydrates) in percentages of 5% – 30%. The formulation was as follows: 160 g flour, 103 mL warm water, 3 g yeast (Tradipan®), 1.3 g salt (La Fina), 2 g sugar (standard), 5 g butter (La Gloria unsalted) and 2 g of powdered milk (Nido®). All the ingredients were incorporated manually until a homogeneous mass was obtained, 23 g portions were made by placing them in a previously greased cupcake baking mold (Wilton 2105-6819 non-stick 26.2 x 41.5 cm), the tray was covered with self-adhesive plastic placing it in a fermentor (Infrico, F848) at 30 °C for 40min, 70% RH, were steam baked (Hornos América, H3mil) at 180°C until cooked (Mérida Lira et al., 2023).

2.3 Taking pictures

For each treatment, including the control, 3 images of each view of the bread (top, side and bottom) and three images of the crumb were obtained. The photographs were obtained with a standardized size of 1280 x 720 pixels in jpg format, at a distance of 20 cm between the lens and the surface where the samples were placed, following concepts of image standardization. The photographs were captured with the help of an amzoom® camera coupled to a 2X stereoscopic microscope (EcolineMatic SZ 745). To establish the pixel-millimeter reference scale, the image of a magnetic stirrer of known size was used, calculated using the measurement bar provided by the microscope software (Gómez-de-Mariscal et al., 2021).

2.4 Morphometric analysis

The morphometric analysis of the loaves and the alveoli in the bread crumb were carried out by processing photographs in jpg format. by automated identification of particle contours and particle analysis using the free-use software ImageJ from the National Institutes of Health, USA in its version 1.5e (Cuervas-Mons et al., 2019). The parameters selected for its quantification were area, perimeter, circularity, Feret, radius aspect, roundness and solidity of the particles. Image processing included the auto-adjustment of brightness, conversion of images to 8-bit images, converting images to black and white format, the delimitation of contours and the analysis of particles, all through image processing by ImageJ. For the bread samples, the particle contours corresponding to the top, side and bottom views (Figure 1) were analyzed in triplicate, while in the crumb n particles were analyzed corresponding to the number of pores detected by the particle analysis.

Figure 1. Top, side and bottom view of bread a) Control bread = 100% HT, b) Bread5% HSPa + 95% HT. c) Bread10% HSPa + 90% HT. d) Bread15% HSPa + 85% HT. e) Bread20% HSPa + 80 % HT. f) Bread25% HSPa + 75% HT. g) Bread30% HSPa + 70% HT.

2.5 Color analysis

Images in jpg format were analyzed as described by Hartig (2013). The images were selected without scaling processing, for each bread image and each crumb image, 5 areas were selected using the ImageJ software with a measurement of 10,000 pixels for the analysis, it was selected to analyze and later to analyze by histogram, this tool allowed to visualize the distribution of frequencies, of the pixels corresponding to the colors of the RGB system (Reds, Greens and Blues) and the balance of these colors, through the average of pixels. The data is expressed as the average number of pixels corresponding to each value obtained from 15 repetitions per treatment.

2.6 Statistical analysis

The experimental design corresponded to a completely random arrangement, the results were obtained with an n = 3 and n for loaves and alveoli for the morphometric analysis, while for color evaluation an n=15 was obtained for both types of sample, the analysis statistical analysis was performed by analysis of variance (ANOVA) Yij= m + ti+ gj + eij., with a comparison of Tukey (normal distribution data) and Scheffé (F distribution data) means for variables with significant treatment effect (p < 0.05). The correlation between the size of the loaves and the percentage addition of HSPa was calculated using a linear regression model (equation 1) and the Pearson correlation index (equation 2) with values between -1 and 1, where values close to -1 indicate a negative correlation. A standardized score data normalization was performed on the pore perimeter variable using equation 3.

Y = a x + b (1)

(2)

(2)

[X-μ] / σ (3)

3. Results and discussion

3.1 Morphometric description of bread

The morphometric analysis showed a negative correlation between the percentage addition of HSPa and the size of the loaves (Table 1), the R2 values were between 0.8634 (top view) and 0.8801 for the lateral view, indicating a greater dependence of the lateral size of the bread with respect to the addition of flour, it has previously been reported that the values of volume, weight and specific volume can decrease when partially substituting wheat flour (Bouaziz et al., 2010; Giami, 2003), breads added with date flour, registered smaller sizes (5.01 ± 0.01) compared to the control (8.26 ± 0.00) before a substitution of 3%, while box bread registered a decrease in volume from 6.25 to 2.04 cm3/g before 25% addition of pumpkin seed flour (Bouaziz et al., 2010; Giami, 2003), in the same way, the Pearson index values indicate a negative correlation where the higher the percentage aggregation of HSPa, a decrease in the size of the bread is observed in the three views evaluated, with values from -0.929 to -0.938, confirming a greater effect in the decrease in size in the side view of the bread. This may be due to the reduction of gluten in the bread formulation by integrating addition of HSPa, limiting the interactions between proteins (gliadins and glutenins) of wheat flour. In addition, papaya seed fibers can limit bread expansion during the fermentation process. However, the reduction in specific volume can be compensated by obtaining firmer textures in the breads obtained (Mérida Lira et al., 2023).

Table 1

The correlation values are calculated between the morphometric measurements of the area and the observed substitution of the values of wheat flour by HSPa.

Bread view analysis | Top | Side | Bottom |

Linear regression (R2) | 0.8634 | 0.8801 | 0.8713 |

Pearson index | -0.929 | -0.938 | -0.933 |

The parameters that complement the morpho-metric analysis of the bread are described in table 2, the circularity parameters (between 0.8433 ± 0.00 and 0.8833 ± 0.01), radius aspect (between 1.03 ± 0.01 and 1.10 ± 0.01) and roundness (between 0.90 00 ± 0.02 and 0.9700 ± 0.01), showed that the breads present low values for the parameters that define a spherical shape, even when the data correspond to the upper and lower view, in addition, it was observed that the percentage HSPa, does not affect these characteristics in obtaining bread, since the values did not present statistical significance for these values between the treatments. However, obtaining these parameters can help characterize innovation processes in bakeries, seeking to standardize the products under study (Binte Abdul Halim et al., 2023). On the other hand, the perimeter values maintained a downward trend as the percentage addition of papaya seed meal increased (p < 0.05), where the control treatment showed the highest values with 223.78 ± 5.35, 223.62 ± 2.82 and 216.77 ± 9.72 mm for the top, side and bottom views respectively. The Feret index showed a similar behavior with values of 69.23 ± 2.88, 70.72 ± 1.04 and 67.43 ± 3.61 for the upper, lateral and lower views of the control, respectively. Previously, breads with the addition of 10% pomegranate seed showed a decrease in length (129.5 mm) and height (50.7 mm), compared to control bread (131.7 and 68.5 respectively) (Gül & Şen, 2017). Finally, the solidity index was 0.99 with no differences between treatments, evidencing an analysis of homogeneous particles (Cuervas-Mons et al., 2019).

In addition, the perimeter parameters of the particles were obtained where the bread10% treatment showed the alveoli with the highest value with 2.43 ± 10.04, when HSPa was added, as well as circularity (0.6935 ± 0.25) and roundness (0.6236 ± 0.19) of the control treatment showed the development of alveoli with oval morphometry, a situation that coincides with a higher value in the radius aspect (1.80 ± 0.70), so that when adding HSPa the alveoli presented a greater tendency to roundness, up to 0.7650 ± 0.24 in bread20% (Table 3), results similar to those reported by Scheuer et al. (2015), where they reported values of 0.807 ± 0.007 before fat substitution in baking presented the lowest alveolar proportion in its analyzed structure with a solidity of 0.7986 ± 0.14, values higher than those reported for untreated wheat bread, which has reported an average of 70.2% porosity, indicating that the breads in this study, it tends to develop a smaller size than other reports (Dessev et al., 2020). However, the alveolate proportion is high. The results of the present study may also be dependent on the ingredients of the dough and its processing conditions (Barros et al., 2022; Cao et al., 2022), the activity of yeast, fermentation temperature and gas bubble formation (Sun et al., 2023; Vicente et al., 2024). As well as the quality and quantity of the protein present in wheat flour (Ferreyra et al., 2021).

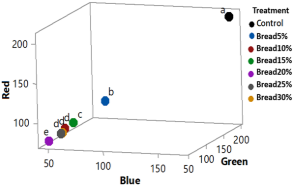

3.4 Color description in breadcrumbs

The color in the crumb showed a trend similar to that present in the evaluated bread, where the control presented values of 205.89 ± 5.21, 196.99 ± 6.15 and 170.06 ± 7.72 for red, green and blue respectively, while the treatments added with papaya seed meal showed statistically lower values (p < 0.05) for both red (75.69 ± 3.22 to 118.25 ± 9.919) and green (57.01 ± 2.83 to 99.62 ± 10.93) and blue (47.77 ± 2.54 at 85.81 ± 10.44), These values are lower than those reported by Gonzalez-Viejo et al. (2022), where breads made with Emmer wheat flour yielded values of 143.33, 113.33 and 80.50 for RGB, which indicates the development of darker breads, as well as what reported by Pečivová et al. (2014), who added grape seed flour, before the addition, obtained in a qualitative way the darkest bread before the addition of 10% of alternative flour. On the other hand, the bread5% treatment was the one that maintained color parameters closest to the control, although it was statistically lower (p < 0.05), while the bread20% treatment showed the greatest tendency to dark coloration and even less RGB balance, when it did not present the highest addition of papaya seed meal (Figure 4). The development of this coloration in bread may be associated with the presence of pigments such as β-cryptoxanthin, α-carotene, β-carotene and lycopene, present in papaya seeds, where it has also been observed that they increase as the fruit matures (Ovando-Martinez et al., 2018).

Figure 4. Color parameters (n = 15) in breadcrumbs added with papaya seed flour, different letters indicate significant difference in RGB balance (p < 0.05). HT= wheat flour. HSPa= papaya seed flour. Control bread= 100% HT. Bread5% HSPa + 95% HT. Bread10% HSPa + 90% HT. Bread15% HSPa + 85% HT. Bread20% HSPa + 80% HT. Bread25% HSPa + 75% HT. Bread30% HSPa + 70% HT.

The results obtained in this research indicate that the use of computerized (artificial) vision techniques to measure the color of food is viable in bakery products (Olakanmi et al., 2023). Likewise, these computational techniques that are developed in combination with a digital camera and processing software of images have been used to provide a least expensive and most versatile method of measuring the morphometric and alveolar characteristics of bread (Ali et al., 2021).

4. Conclusions

The data obtained indicated that the color and the porosity of the crumb, showed dependence with the percentage of substitution of wheat flour by HSPa. Furthermore, no substantial modification of the morphometric characteristics of the breads was found. The use of computer-based image processing techniques presents advantages such as objectivity, consistency and efficiency to quantitatively characterize the properties of color, size and shape in the evaluation of food quality, these techniques allow preserving the precision of measurements and they help to reduce the inconsistency in the subjectivity of manual measurements, offering flexibility in their application since highly expensive equipment is not required. Due to these characteristics, its use can be an important tool in decision-making in product innovation in the food area. In the same way, the use of digital tools for image analysis as a means of quantifying color and alveolar composition of bread, can broaden the perspective as a viable method of evaluation since it allows determining the relationship between physical parameters and bakery quality for different types of bread. Finally, the use of HSPa can be suggested as an unconventional ingredient, for the preparation of bakery products, its use allows obtaining breads that do not alter their morphometric characteristics, with a dark brown coloration and with the presence of alveoli of smaller in size, but with a higher percentage presence in the composition of the bread. In the same way, this allows the use of fruit fractions that are considered rights in the agricultural industry, as sources of fiber and other components of high biological value such as pigments, more studies are recommended to continue with the characterization of the potential use of the seeds of papaya and other fruits in the food industry.

References

Ahanchi, M., Sugianto, E. C., Chau, A., & Khoddami, A. (2024). Quality Properties of Bakery Products and Pasta Containing Spent Coffee Grounds (SCGs): A Review. Foods, 13(22), 1–21. https://doi.org/10.3390/foods13223576

Al-Hooti, S. N., Sidhu, J. S., Al-Saqer, J. M., & Al-Othman, A. (2002). Effect of raw wheat germ addition on the physical texture and objective color of a designer food (pan bread). Nahrung - Food, 46(2), 68–72. https://doi.org/10.1002/1521-3803(20020301)46:2<68::AID-FOOD68>3.0.CO;2-W

Ali, S., Mayo, S., Gostar, A. K., Tennakoon, R., Bab-Hadiashar, A., Cann, T. M., Tuhumury, H., & Favaro, J. (2021). Automatic segmentation for synchrotron-based imaging of porous bread dough using deep learning approach. Journal of Synchrotron Radiation, 28, 566–575. https://doi.org/10.1107/S1600577521001314

Archandani, R. B., Mohanna, F., & Ahsani, M. J. (2022). Introducing an Automatic Bread Quality Assessment Algorithm using Image Processing Techniques. European Journal of Electrical Engineering and Computer Science, 6(6), 31–38. https://doi.org/10.24018/ejece.2022.6.6.470

Barros, J. H. T., Ribeiro, V. A. da G., Ferreira, M. de P. K., & Steel, C. J. (2022). Bread-making performance of wheat flours enriched with vital gluten treated with non-thermal plasma. International Journal of Food Science and Technology, 57(6), 3795–3803. https://doi.org/10.1111/ijfs.15708

Bertrand, D., Guerneve, C., Marion, D., Devaux, F., & Robert, P. (2020). Description of the textural appearence of bread crumb by video image analysis. Cereal Chem., 21(1), 1–9. http://journal.um-surabaya.ac.id/index.php/JKM/article/view/2203

Bicalho, C. C., Madeira, R. A. V., Pereira, J., & Scalon, J. D. (2019). Alveolar distribution in French rolls made using taro mucilage. Brazilian Journal of Food Technology, 22, 1–10. https://doi.org/10.1590/1981-6723.00618

Binte Abdul Halim, F. N., Taheri, A., Abdol Rahim Yassin, Z., Chia, K. F., Goh, K. K. T., Goh, S. M., & Du, J. (2023). Effects of Incorporating Alkaline Hydrogen Peroxide Treated Sugarcane Fibre on The Physical Properties and Glycemic Potency of White Bread. Foods, 12(7), 1–19. https://doi.org/10.3390/foods12071460

Bohl, M., Gregersen, S., Zhong, Y., Hebelstrup, K. H., & Hermansen, K. (2024). Beneficial glycaemic effects of high-amylose barley bread compared to wheat bread in type 2 diabetes. European Journal of Clinical Nutrition, 78(3), 243–250. https://doi.org/10.1038/s41430-023-01364-x

Bouaziz, M. A., Amara, W. Ben, Attia, H., Blecker, C., & Besbes, S. (2010). Effect of the addition of defatted date seeds on wheat dough performance and bread quality. Journal of Texture Studies, 41(4), 511–531. https://doi.org/10.1111/j.1745-4603.2010.00239.x

Cao, H., Wang, X., Wang, X., Guan, X., Huang, K., & Zhang, Y. (2022). Effect of storage conditions on the textural properties and in vitro digestibility of wheat bread containing whole quinoa flour. Food Bioscience, 49(July), 101921. https://doi.org/10.1016/j.fbio.2022.101921

Cuervas-Mons, J., Rodríguez-Rey, Á., Ordóñez-Casado, B., & Berrezueta, E. (2019). Análisis cuantitativo de parámetros de forma de partículas minerales 2D mediante técnicas digitales. Computers and Geosciences, 77(1), 97–110. https://doi.org/10.1016/j.cageo.2015.01.005

Curti, M. I., Palavecino, P. M., Savio, M., Baroni, M. V., & Ribotta, P. D. (2023). Sorghum (Sorghum bicolor L. Moench) Gluten-Free Bread: The Effect of Milling Conditions on the Technological Properties and In Vitro Bioaccessibility of Polyphenols and Minerals. Foods, 12(16), 1–19. https://doi.org/10.3390/foods12163030

Dessev, T., Lalanne, V., Keramat, J., Jury, V., Prost, C., & Le-Bail, A. (2020). Influence of Baking Conditions on Bread Characteristics and Acrylamide Concentration. Journal of Food Science and Nutrition Research, 03(04), 291–310. https://doi.org/10.26502/jfsnr.2642-11000056

Di Renzo, T., Trivisonno, M. C., Nazzaro, S., Reale, A., & Messia, M. C. (2024). Effect of Different Hydrocolloids on the Qualitative Characteristics of Fermented Gluten-Free Quinoa Dough and Bread. Foods, 13(9). https://doi.org/10.3390/foods13091382

Ferreyra, L. S., Verdini, R. A., Soazo, M., & Piccirilli, G. N. (2021). Impact of whey protein addition on wheat bread fermented with a spontaneous sourdough. International Journal of Food Science and Technology, 56(9), 4738–4745. https://doi.org/10.1111/ijfs.15052

Francavilla, A., & Joye, I. J. (2022). Anthocyanin Content of Crackers and Bread Made with Purple and Blue Wheat Varieties. Molecules, 27(21), 1–14. https://doi.org/10.3390/molecules27217180

Genevois, C. E., & de Escalada Pla, M. F. (2021). Soybean by-products and modified cassava starch for improving alveolar structure and quality characteristics of gluten-free bread. European Food Research and Technology, 247(6), 1477–1488. https://doi.org/10.1007/s00217-021-03725-x

Giami, S. Y. (2003). Effect of germination on bread-making properties of wheat-fluted pumpkin (Telfairia occidentalis) seed flour blends. Plant Foods for Human Nutrition, 58(3), 1–9. https://doi.org/10.1023/B:QUAL.0000040314.25512.8e

Gómez-de-Mariscal, E., García-López-de-Haro, C., Ouyang, W., Donati, L., Lundberg, E., Unser, M., Muñoz-Barrutia, A., & Sage, D. (2021). DeepImageJ: A User - Friendly Plugin To Run Deep Learning Models in I Mage J. Nature Methods, Dl, 1–13. https://doi.org/https://doi.org/10.1101/799270

Gómez, M., Gutkoski, L. C., & Bravo-Núñez, Á. (2020). Understanding whole-wheat flour and its effect in breads: A review. Comprehensive Reviews in Food Science and Food Safety, 19(6), 3241–3265. https://doi.org/10.1111/1541-4337.12625

Gonzalez Viejo, C., Harris, N. M., & Fuentes, S. (2022). Quality Traits of Sourdough Bread Obtained by Novel Digital Technologies and Machine Learning Modelling. Fermentation, 8(10), 1–16. https://doi.org/10.3390/fermentation8100516

Grenier, D., Rondeau-Mouro, C., Dedey, K. B., Morel, M. H., & Lucas, T. (2021). Gas cell opening in bread dough during baking. Trends in Food Science and Technology, 109(January), 482–498. https://doi.org/10.1016/j.tifs.2021.01.032

Gül, H., & Şen, H. (2017). Efectos de la harina de semilla de granada en la reología de la masa y en la calidad del pan. CYTA - Journal of Food, 15(4), 622–628. https://doi.org/10.1080/19476337.2017.1327461

Hartig, S. M. (2013). Basic image analysis and manipulation in imageJ. Current Protocols in Molecular Biology, SUPPL.102, 1–12. https://doi.org/10.1002/0471142727.mb1415s102

Hasan, M. M., Islam, M. R., Haque, A. R., Kabir, M. R., & Hasan, S. M. K. (2024). Fortification of bread with mango peel and pulp as a source of bioactive compounds: A comparison with plain bread. Food Chemistry Advances, 5(July), 100783. https://doi.org/10.1016/j.focha.2024.100783

Hernández-López, I., Alamprese, C., Cappa, C., Prieto-Santiago, V., Abadias, M., & Aguiló-Aguayo, I. (2023). Effect of Spirulina in Bread Formulated with Wheat Flours of Different Alveograph Strength. Foods, 12(20), 1–18. https://doi.org/10.3390/foods12203724

Komeroski, M. R., Homem, R. V., Schmidt, H. de O., Rockett, F. C., de Lira, L., Vitória da Farias, D., Kist, T. L., Doneda, D., Rios, A. de O., & Ruffo de Oliveira, V. (2021). Effect of whey protein and mixed flours on the quality parameters of gluten-free breads. International Journal of Gastronomy and Food Science, 24(December 2020), 1–9. https://doi.org/10.1016/j.ijgfs.2021.100361

Maietti, A., Tedeschi, P., Catani, M., Stevanin, C., Pasti, L., Cavazzini, A., & Marchetti, N. (2021). Nutrient composition and antioxidant performances of bread-making products enriched with stinging nettle (Urtica dioica) leaves. Foods, 10(5), 1–10. https://doi.org/10.3390/foods10050938

Mérida Lira, E., Soto Simental, S., Martínez Juárez, V. M., Quintero Lira, A., & Piloni Martini, J. (2023). Proximate chemical, functional, and texture characterization of papaya seed flour (Carica papaya) for the preparation of bread. International Journal of Gastronomy and Food Science, 31(October 2022), 1–8. https://doi.org/10.1016/j.ijgfs.2023.100675

Milla, P. G., Peñalver, R., & Nieto, G. (2021). Health benefits of uses and applications of moringa oleifera in bakery products. Plants, 10(2), 1–17. https://doi.org/10.3390/plants10020318

Olakanmi, S. J., Jayas, D. S., & Paliwal, J. (2023). Applications of imaging systems for the assessment of quality characteristics of bread and other baked goods: A review. Comprehensive Reviews in Food Science and Food Safety, 22(3), 1817–1838. https://doi.org/10.1111/1541-4337.13131

Ovando-Martinez, M., López-Teros V., M., Tortoledo-Ortiz, O., Astiazarán-García, H., Ayala-Zavala, J. F., Villegas-Ochoa, M. A., & González-Aguilar, G. A. (2018). Effect of ripening on physico-chemical properties and bioactive compounds in papaya pulp, skin and seeds. Indian Journal of Natural Products and Resources, 9(1), 47–59.

Pečivová, P. B., Kráčmar, S., Kubáň, V., Mlček, J., Jurikova, T., & Sochor, J. (2014). Effect of addition of grape seed flour on chemical, textural and sensory properties of bread dough. Mitteilungen Klosterneuburg, 64(3), 114–119.

Scheuer, P. M., Ferreira, J. A. S., Mattioni, B., de Miranda, M. Z., & de Francisco, A. (2015). Optimization of image analysis techniques for quality assessment of whole-wheat breads made with fat replacer. Food Science and Technology (Brazil), 35(1), 133–142. https://doi.org/10.1590/1678-457X.6560

Sugiharto, S. (2020). Papaya (Carica papaya L.) seed as a potent functional feedstuff for poultry - A review. Veterinary World, 13(8), 1613–1619. https://doi.org/10.14202/vetworld.2020.1613-1619

Sun, X., Scanlon, M. G., Nickerson, M. T., & Koksel, F. (2023). The entrainment and evolution of gas bubbles in bread dough—A review. Cereal Chemistry, 100(5), 1031–1047. https://doi.org/10.1002/cche.10699

Vicente, P., Pires, M. J., & Félix, N. (2024). Development and acceptance of sourdough breads fermented by endogenous yeasts of Pyrus communis, Malus domestica and Pistacia lentiscus. Experiencing and Envisioning Food, 217–223. https://doi.org/10.1201/9781003386858-31

(2)