Suspension stability of passion fruit nectar formulated with carboxymethyl cellulose: Analysis of sedimentation kinetics

Estabilidad de suspensión de néctar de maracuyá formulado con carboximetilcelulosa: Análisis de la cinética de sedimentación

Jesús Noel-Cuya1; Sheyla H. Ureta1; Felix Torres-Pino1; Victor Aredo2 *

1 Escuela de Ingeniería Agroindustrial, Facultad de Química e Ingeniería Química, Universidad Nacional Mayor de San Marcos, Av. Fernando Wiesse 4756, SJL, Lima, Perú.

2 Departamento de Operaciones Unitarias, Facultad de Química e Ingeniería Química, Universidad Nacional Mayor de San Marcos, Av. República de Venezuela s/n, Lima, Perú.

ORCID de los autores:

J. Noel-Cuya: https://orcid.org/0009-0000-2618-4088 S. H. Ureta: https://orcid.org/0009-0008-7459-5947

F. Torres-Pino: https://orcid.org/0009-0001-9688-8977 V. Aredo: https://orcid.org/0000-0002-3293-7696

ABSTRACT

This study evaluated the suspension stability of passion fruit nectar formulated with different concentrations of carboxymethyl cellulose (CMC). Passion fruit nectars with 0, 0.02, 0.1 and 0.2% (w/v) CMC were placed at rest in test tubes at room temperature (~25 °C) to measure the phase separation height for 87 h. Passion fruit nectars with 0 and 0.02% (w/v) CMC showed notable phase separation, while those with 0.1 and 0.2% (w/v) CMC were relatively stable suspensions. The analysis of sedimentation kinetics revealed that passion fruit nectars with 0 and 0.02% (w/v) CMC presented respectively: maximum sedimentation velocity of 0.426 m/s and 0.260 m/s, equilibrium sedimentation index of 46.494% and 20.434%, and sedimentation rate speed of 0.0362 and 0.0556%/s. A concentration of 0.2% (w/v) CMC is recommended in passion fruit nectar to maintain the appearance of a stable suspension, which is a characteristic desired by the consumer.

Keywords: fruit nectar; stabilizers; hydrocolloids; sedimentation; particle suspension.

RESUMEN

Este estudio evaluó la estabilidad de suspensión del néctar de maracuyá formulado con diferentes concentraciones de carboximetilcelulosa (CMC). Néctares de maracuyá con 0, 0.02, 0.1 y 0.2% (m/v) de CMC fueron colocadas en reposo en probetas a temperatura ambiente (~25 °C) para medir la altura de separación de fases durante 87 h. Néctares de maracuyá con 0 y 0.02% (m/v) CMC presentaron notoria separación de fases, mientras que aquellos con 0.1 y 0.2% (m/v) de CMC fueron suspensiones relativamente estables. El análisis de la cinética de sedimentación reveló que los néctares de maracuyá con 0 y 0.02% (m/v) CMC presentaron respectivamente: velocidad máxima de sedimentación de 0.426 m/s y 0.260 m/s, índice de sedimentación de equilibrio de 46.494% y 20.434%, y velocidad de índice de sedimentación de 0.0362 y 0.0556%/s. Se recomienda una concentración de 0.2% (m/v) CMC en el néctar de maracuyá para que mantenga apariencia de suspensión estable, la cual es una característica deseada por el consumidor.

Palabras clave: néctar de fruta, estabilizantes, hidrocoloides, sedimentación, suspensión de partículas.

1. Introduction

Passion fruit (Passiflora edulis) is a fruit native of tropical America that contains valuable compounds for human nutrition such as vitamin C, dietary fiber, vitamin B, iron, and phosphorus (He et al., 2020; Zhang et al., 2023). This fruit is of interest to the food industry, particularly in ready-to-drink products such as nectar, since its pulp has an intense characteristic acidic flavor that allows it to be diluted and sweetened, achieving high sensory acceptability (Soares et al., 2024; Honorio et al., 2021). Fruit nectar formulated with pulp contains suspended solids with a density greater than that of water. These solids are prone to sedimentation when the product is at rest, which is perceived as a notable separation of phases, causing rejection by consumers (Laz et al., 2018). The most practical way to prevent this defect is by adding hydrocolloids to the formulation that physically stabilize the suspension of solid particles mainly by increasing the product viscosity (Silva et al., 2019; Contreras-Lozano et al., 2019).

The evaluation of the use of hydrocolloids for physical stabilization in fruit nectar remains a topic of current interest, for example, the following applications have been studied: carboxymethyl cellulose (CMC), carrageenan and pectin in nectar from Citrus nobilis L. (Aini et al., 2022), mucilage of Dioscorea rotundata and CMC in nectar of Mangifera indica L. (Lozano et al., 2020), xanthan gum and CMC in mixed nectar of Citrus sinnensis and Citrus reticulata (Andrade et al., 2022), mucilage of Theobroma cacao in nectar of Artocarpus heterophyllus (Flor et al., 2023), and mucilage of Salvia hispanica in nectar of Passiflora edulis (Soares et al., 2024), gum of Caesalpinia spinosa, CMC and xanthan gum in mixed nectar of Passiflora edulis and Daucus carota (Prado & Cangana, 2021). Among the hydrocolloids of interest for this practical application, CMC stands out in the food industry for its high commercial availability, low cost and improvement in the acceptability of sensory attributes related to consistency (texture) of fruit nectars (Akkarachaneeyakorn & Tinrat, 2015; Lozano et al., 2020; Aini et al., 2022).

This research aimed to evaluate the suspension stability of passion fruit nectar formulated with different concentrations of CMC based on the analysis of sedimentation kinetics.

2. Methodology

Nectar production

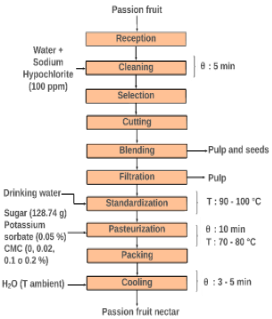

The passion fruit nectar production process followed in this research (Figure 1) is based on the processes described by Laz et al. (2018) and Prado & Cangana (2021).

Figure 1. Flowchart for the production of passion fruit nectar.

The yellow Creole passion fruit (Passiflora edulis) fruits, without mechanical damage or the presence of pests, were purchased at the 27 de octubre market in San Juan de Lurigancho (Lima, Peru). The fruits were washed to remove impurities and disinfected with sodium hypochlorite (100 ppm) for 5 minutes. Subsequently, the fruits were cut in half to extract the pulp and seeds. The size of the pulp and seeds was reduced with a household blender (Oster, Professional series 700W BLSTBPST, China) for 50 seconds at the single speed level. Then the pulp with seed fragments was filtered through a polypropylene strainer (1 mm2 fissure) (Rey, Peru) to obtain pulp with minimal seed fragments. The filtered pulp was diluted in hot boiled water (80°C) in a pulp/water ratio of 1:3 v/v. The diluted pulp was pasteurized (70-80°C for 10 min). At minute 8 of this heat treatment, a known amount of white sugar (Paramonga, Peru) was added to reach the desired °Brix, 0.05% w/v potassium sorbate (Marva, Peru), and 0, 0.02, 0.1 or 0.2% (w/v) CMC (Marva, Peru) were added slowly with constant stirring to facilitate dissolution. Finally, the nectar was hot-packed and quickly cooled with water at room temperature to improve microbiological stability.

Physicochemical parameters such as °Brix and pH were analyzed during the production of passion fruit nectar. The °Brix were determined with a refractometer (SBR0080, Lumen Optical Instrument Co., Ltd, Beijing, China) and pH was measured with pH test strips (pH X®, ColorKim, Turkey). The °Brix value of passion fruit nectar was set at the value of 14 considering recommendations for similar products since this parameter can be set at the value of 15 (Curo and Ibañez, 2017), 18-19 (Laz et al., 2018), 12.8 (Prado and Cangana, 2021) or 14.5 °Brix (Codex Alimentarius). The pH value of passion fruit nectar was 4.5, it did not require adjustment with the addition of citric acid because this value is similar to the pH of 4 reported in a similar product (Laz et al., 2018) and did not exceed the pH of 4.5 recommended by Peruvian regulations (Norma Técnica Peruana, 2009). It is worth mentioning that the final addition of CMC in the different concentrations evaluated did not alter the °Brix value and the pH of the passion fruit nectar.

Sedimentation analysis

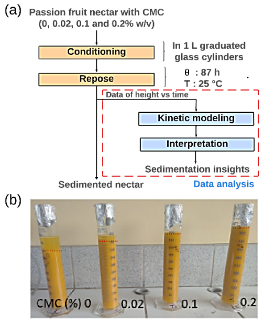

This analysis was based on the visualization of the sedimentation phenomenon (Figure 2). For this, the passion fruit nectars with different concentrations of CMC upon leaving pasteurization were deposited in 1L graduated glass cylinders, which were covered in the mouth with aluminum foil to avoid contamination. Cooling was carried out with water at room temperature for 3-5 minutes. Finally, the graduated cylinders containing the passion fruit nectar remained at rest at room temperature (~25 °C) to evaluate sedimentation for 87 hours (Figure 2a).

Figure 2. Sedimentation analysis of passion fruit nectar with different CMC concentrations (%) w/v: (a) flowchart and (b) visualization of phase separation.

This evaluation was based on the Coe and Clevenger (1916) method cited by Parsapour et al. (2014). This consisted of recording pairs of values (height of the solids-rich phase, time) that make up the sedimentation curve (Figure 2b). The analysis of sedimentation kinetics was substantiated on the equations used by Silva et al. (2010) and Contreras-Lozano et al. (2019): Vt = -dht/dt, SI = (h0 – ht)*100/h0 and SI=SIeq*(1-exp(-vsi*t)); where Vt: sedimentation velocity (cm/h), t: time (h), ht: height (cm) of the sediment at the time “t”, h0: initial height (cm), SI: sedimentation index, SIeq: SI equilibrium, vsi: SI velocity constant.

3. Results and discussion

The sedimentation analysis for 87 hours (Figure 3a), in terms of phase height, revealed that the higher the concentration of CMC, the sedimen-tation is lower to the point of not being relevant in passion fruit nectars with 0.1 and 0.2% w/v of CMC, which can be considered relatively stable solutions. The typical sedimentation profile was observed at concentrations of 0 and 0.02% w/v CMC, which consists of a period of maximum sedimentation velocity (0.426 and 0.260 m/s at 0 and 0.02% w/v CMC, respectively) in the first 22 hours with a subsequent gradual decrease in velocity until approaching equilibrium (sedimen-tation velocity = ~ 0) (Figure 3a). Thus, a low concentration of CMC (0.02% w/v) significantly decreases the maximum sedimentation velocity in passion fruit nectar without stabilizer. Sedimentation kinetics can also be studied regarding the sedimentation index to obtain complementary information when the typical sedimentation profile is observed (Figure 3b). The sedimentation index values observed at concentrations of 0 and 0.02% w/v CMC were successfully described by the kinetic model (R2>0.99) based on equations by Silva et al. (2010) and Contreras-Lozano et al. (2019). The equilibrium sedimentation index was 46.494 and 20.434% for 0 and 0.02% w/v CMC, respectively. This parameter can be understood as the maximum achievable sedimentation index value, so it can be stated that a low concentration of CMC (0.02% w/v) in passion fruit nectar can reduce the maximum sedimentation index to less than half compared to no using stabilizer. The sedimentation index velocity was 0.0362 and 0.0556% m/s for 0 and 0.02% w/v CMC, respectively. This reveals that when no stabilizer is used, passion fruit nectar is slow to reach the equilibrium sedimentation index compared to using of a low CMC concentration (0.02% w/v).

It is important to highlight that this work establi-shed that the sedimentation velocity and sedimentation index velocity provide different information, consequently there is a broadening of the analysis perspective.

The results of the analysis of sedimentation kinetics of in passion fruit nectar with different concentrations of CMC are consistent with other investigations where a higher concentration of hydrocolloid decreased the intensity of sedimentation phenomena in this product, as is the case of the study carried out by Laz et al. (2018), where they used xanthan gum and highly esterified pectin (ceam pectin VIS 4110) to provide better stability; and the case of the research by Moraes et al. (2011), in which they used guar gum and xanthan gum to achieve a more stable and structured passion fruit pulp dispersion.

Thus, it is suggested that a higher concentration of hydrocolloid implies a greater capacity to capture water molecules in three-dimensional networks and nectar components, including solid microparticles and compounds such as the insoluble pectate generated by the activity of pectin methyl esterase that was solubilized by effect of heat treatment and low pH, which leads to an increase in viscosity, improvement in the stability and uniformity of the suspension (Genovese & Lozano, 2001; Caballero & Paredes, 2017; Akkarachaneeyakorn & Tinrat, 2015; Staubmann et al., 2023; Aghajanzadeh et al., 2017).

4. Conclusions

The sedimentation phenomenon in passion fruit nectar was minimized when a concentration of 0.1-0.2% w/v CMC is used.

Parameters such as sedimentation velocity, equilibrium sedimentation index, and sedimentation index velocity were affected by CMC concentration. These results contribute to a better understanding of the use of CMC to improve the physical stability of nectar suspension and to gain insights into the formulation and improvement of similar products in the food industry.

It is recommended to carry out comparative studies on sedimentation kinetics in fruit nectars formulated with different concentrations of natural and/or synthetic stabilizers. These studies should include other aspects of interest to the food industry, such as cost and effect on sensory characteristics of the product.

References

Aghajanzadeh, S., Ziaiifar, A. M., & Kashaninejad, M. (2017). Influence of thermal treatment, homogenization and xanthan gum on physicochemical properties of watermelon juice: A response surface approach. LWT - Food Science & Technology, 85, 66-74. https://doi.org/10.1016/j.lwt.2017.07.007

Aini, N., Dwiyanti, H., Setyawati, R., Handayani, I., Septiana, A. T., Sustriawan, B., & Aena, D. A. Q. (2022). Siam orange (Citrus nobilis L.) nectar characteristics with variations in stabilizer and sucrose level. Food Research, 6(3), 315-323. https://doi.org/10.26656/fr.2017.6(3).386

Akkarachaneeyakorn, S., & Tinrat, S. (2015). Effects of types and amounts of stabilizers on physical and sensory characteristics of cloudy ready‐to‐drink mulberry fruit juice. Food science & nutrition, 3(3), 213-220. https://doi.org/10.1002/fsn3.206

Andrade, E. F. M., Lucas, F. M. D., Mendoza, L. A. Z., Vera, E. F. S., Solorzano, J. V. S., & Mendoza, B. A. Z. (2022). Estabilidad de néctar mix de pulpa de naranja (Citrus sinnensis) y mandarina (Citrus reticulata) con goma xanthan y cmc. La Técnica, (27), 1-12. https://doi.org/10.33936/la_tecnica.v0i27.3897

Caballero, E., & Paredes, L. (2017). Formulación y evaluación de néctar a base de guanábana (Annona muricata) y quinua (Chenopodium quinoa) edulcorada con estevia (Stevia rebaudiana) [Tesis para obtener el Título Profesional de Ingeniero Agroindustrial. Universidad Nacional del Santa.

Codex Alimentarius. (2005). Norma general para zumos (jugos) y néctares de frutas (CODEX STAN 247-2005). www.codexalimentarius.org

Coe, H.S., & Clevenger, G.H. (1916). Methods for determining the capacities of slime settling tanks. Transactions American Institute of Mining Engineering, 55, 356-384.

Contreras-Lozano, K.P., Ciro-Velásquez, H.J., & Arango-Tobón, J.C. (2019). Hidrocoloides como estabilizantes en bebidas de maíz dulce (Zea mays var. saccharata) y gel de aloe vera (Aloe barbadensis Miller). Revista U.D.C.A Actualidad & Divulgación Científica, 22(2). https://doi.org/10.31910/rudca.v22.n2.2019.1090

Flor, F. I., Macías-Zambrano, M., Napa-Vizuete, B., Vásquez-Cortez, L., Alvarado-Vásquez, K., Revilla-Escobar, K., ... & Vera-Chang, J. (2023). Inclusión de mucílago de cacao (Theobroma cacao) como estabilizante en néctar de jackfruit (Artocarpus heterophyllus). Agroindustrial Science, 13(2), 75-81. https://doi.org/10.17268/agroind.sci.2023.02.03

Gómez, M. C. F., & Pérez, A. G. (2018). Determinación de los parámetros de procesamiento que maximicen el rendimiento y la estabilidad del néctar de ungurahui (Oenocarpus bataua, C. Martius). Revista de la Sociedad Química del Perú, 84(3), 350-361.

He, X., Luan, F., Yang, Y., Wang, Z., Zhao, Z., Fang, J., Wang, M., Zhuo, M., & Li, Y. (2020). Passiflora edulis: An insight into current researches on phytochemistry and pharmacology. Frontiers in pharmacology, 11, 617. https://doi.org/10.3389/fphar.2020.00617

Honorio, A. R., Soares, A. F., Lima, D. C. N., & Tribst, A. A. L. (2021). Passion fruit nectar sweetened with stevia and sucralose: Is perception affected by the regular consumption of sweeteners or diabetes?. International Journal of Gastronomy and Food Science, 25, 100404. doi.org/10.1016/j.ijgfs.2021.100404

Laz, M., Tuárez, M., Bermello, S., & Díaz, E. (2018). Evaluación fisicoquimica en jugo de maracuyá con diferentes concen-traciones de hidrocoloides. ESPAMCIENCIA, 9(2), 119-123.

Moraes, I. C. F., Fasolin, L. H., Cunha, R. L., & Menegalli, F. C. (2011). Dynamic and steady: shear rheological properties of xanthan and guar gums dispersed in yellow passion fruit pulp (Passiflora edulis f. flavicarpa). Brazilian Journal of Chemical Engineering, 28(3), 483-494. https://doi.org/10.1590/S0104-66322011000300014

Norma Técnica Peruana. NTP 203.110. (2009) Jugos, néctares y bebidas de fruta. Requisitos. Comision de Normalizacion y de fiscalizacion de Barreras Comerciales No arancelarias-INDECOPI. Apartado, 145.

Parsapour, G., Hossininasab, M., Yahyaei, M., & Banisi, S. (2014). Effect of settling test procedure on sizing thickeners. Separation and Purification Technology, 122(1), 87–95. https://doi.org/10.1016/j.seppur.2013.11.001

Pérez, A. G., & Vargas, A. R. (2006). Comparación de los floculantes CHEMADD A-41, 42 Y 43 de la Firma CHEMATEK, el IP-600 de la Firma ZAR CIA y el PERCOL, versión canadiense del MAGNAFLOC R-155. Tecnología Química, 26(3), 41-47. https://www.redalyc.org/pdf/4455/445543751006.pdf

Prado, J., & Cangana, R. (2021). Utilización de goma de tara, cmc y goma xantana en la optimización de la elaboración de néctar a base de maracuyá y zanahoria [Tesis de titulación, Universidad Nacional José Faustino Sánchez Carrión].

Silva, L. F. R., Gomes, A. S., Castro, D. R. G., Souza, F. C. A., Mar, J. M., Silva, L. S., Sanchez, E. A., Bezerra, J. A. & Campelo, P. H. (2019). Ultrasound‐assisted homogenization and gum Arabic combined to physicochemical quality of cupuaçu juice. Journal of Food Processing and Preservation, 43(9), e14072. https://doi.org/10.1111/jfpp.14072

Silva, V. M., Sato, A. C. K., Barbosa, G., Dacanal, G., Ciro‐Velásquez, H. J., & Cunha, R. L. (2010). The effect of homogenisation on the stability of pineapple pulp. International journal of food science & technology, 45(10), 2127-2133. https://doi.org/10.1111/j.1365-2621.2010.02386.x

Soares, A. D. C. C., Tavares, M. B. F. B., Ortega, E. D. P. M., Vidigal, M. C. T. R., & Santana, R.S. (2024). Rheological and sensorial evaluation of fruit nectar with chia mucilage. International Journal of Gastronomy and Food Science, 35, 100849. https://doi.org/10.1016/j.ijgfs.2023.100849

Staubmann, L., Mistlberger-Reiner, A., Raoui, E. M., Brunner, G., Sinawehl, L., Winter, M., Liska, R., & Pignitter, M. (2023). Combinations of hydrocolloids show enhanced stabilizing effects on cloudy orange juice ready-to-drink beverages. Food Hydrocolloids, 138, 108436. https://doi.org/10.1016/j.foodhyd.2022.108436

Zhang, J., Tao, S., Hou, G., Zhao, F., Meng, Q., & Tan, S. (2023). Phytochemistry, nutritional composition, health benefits and future prospects of Passiflora: A review. Food Chemistry, 136825. https://doi.org/10.1016/j.foodchem.2023.136825