Influence of temperature on the rheological behavior of industrialized honey

Haydee Rodriguez-Navarro1; David Vivanco-Pezantes2*

1 Faculty of Agriculture and Nutrition. National University of Education Enrique Guzman y Valle, Lima CP 154472, Peru.

2 Faculty of Fisheries and Food Engineering, National University of Callao, Lima CP 07011, Peru.

Author's ORCID:

H. Rodríguez-Navarro: https://orcid.org/0000-0001-7346-4496

D. Vivanco-Pezantes: https://orcid.org/0000-0002-9474-0290

ABSTRACT

In the present work, the effect of temperature on the rheological properties of the industrialized honey of three different high-trade brands in the northern, central and southern Lima markets was studied. The physicochemical characteristics of water activity, specific gravity, moisture content, brix degrees, refractive index and pH were analyzed. No significant difference was found between the values of the physicochemical properties within and between the groups of the commercial brands analyzed (p> 0.05). The industrialized honey was tested with a Brookfield RVDV-E concentric viscometer using a flat disk spindle at five temperature levels from 20 ºC to 60 ºC, and the influence of temperature with dynamic or absolute viscosity was studied. Through the rheogram, a behavior of a Newtonian fluid was observed. For all samples it was found that the mean absolute viscosity decreases with temperature at 20 ºC (7430 mPa∙s), 30 ºC (2636 mPa∙s), 40 ºC (955 mPa∙s), 50 ºC (440 mPa∙s) and 60 ºC (267 mPa∙s). The dependence of the viscosity with the temperature was described by a mathematical exponential model of three constants proposed in this investigation that gave a good fit, obtaining a coefficient of determination of 0.9999. The activation energy value calculated and within the temperature range tested was 68.73±0.129 kJ.mol-1. The results obtained in this study are of great interest to the industry that manipulates and formulates edible foods based on this type of product.

Keywords: Rheological-mathematical modeling; Newtonian fluid; liquid viscosity.

1. Introduction

Rheology is the science that studies the deformation and flow of matter, as such, in food it is applied to all liquid foods, semi-solid foods and solid foods. All these foods must respond to a normal or tangential stress observing a degree of deformation or flow. The importance of the application of this technique goes hand in hand with technology and food processing, because it is necessary to (Moldenaers & Keunings, 1992): (a) Properly dimension the amount of energy to drive a certain flow through a pipe system through which the fluid must be transported with a certain speed and flow; (b) Properly dimension the type of industrial equipment, that is, tube banks, pumping installations, mixers, types of heat exchangers, etc.; (c) In the formulation of food, the influence of an ingredient on the overall behavior of the product; (d) Control the process from the point of view of momentum, heat and mass transport phenomena; (e) Control process quality and product quality; (f) Know through a rheogram or a texture analysis profile the food object of the manufacturing process; (g) Study through the bibliographic references the rheological behavior of the test substance and with these data simulate the behavior in the processing or manufacturing system.

That is, the study of the rheological behavior of the matter contributes to the knowledge of its structure, industrial design and control of the processes and the finish and acceptance of the product (Alexander, Malkin & Auraan, 2017).

The use of calculation methodologies is being applied by the various scientific and industrial activities in process control and equipment design, resulting in cost reduction and exploratory work through simulation processes and in the Food Engineering area, rheology plays a very important role in technological and / or food manufacturing processes, from primary controls to the last stage of manufacturing, rheological analyzes involve, flow design, process control, standardization, and product quality and preliminary rheological studies allow the proper design of engineering processes and product development (Sobato, 2004; Bourne, 1983; Mckenna, 2003; Kress & Brimelow, 2001).

The composition of natural bee honey is quite variable and complex, it depends mainly on its floral source and geographical distribution; however, some external factors, such as seasonal and environmental, also play an important role in its composition. Honey is a supersaturated solution of sugars, of which fructose (38%) and glucose (31%) are the main contributors, with phenolic compounds, minerals, proteins, free amino acids, enzymes, and vitamins acting as minor components (Alvarez-Suarez et al., 2010).

Industrialized honey is natural bee honey to which water, syrup, sugar and glucose have been added in its composition, it generally flows more easily than natural honey. From bibliographic data, light honey is known to be Newtonian in behavior (Messel et al., 2000; Junzheng & Chanying, 1998; Lazaridou, 2004; Kayacier & Karaman, 2008; Singh & Bath, 1997; Terrab et al., 2002; Popek, 2002; Bhandari et al., 1999; Assil et al., 1991; Slawomir et al., 2016; Steffe, 2013).

Honey in general, as well as industrialized honey, has increased in its consumption, due to the contribution of flavonoids, polyphenols, its excellent antioxidant properties, and the important caloric intake, considering it an important product to strengthen the immune system. It is generally used as an ingredient in the baking and pastry industry and in the juice making industry. Likewise, research aimed at the development and creation of hypercaloric foods is currently relevant due to the increase in the standard of living, the so-called "modern diseases of civilization" are presented, obesity being a global epidemic of society that causes a physiological imbalance in the body.

There are several scientific research papers on the rheological characteristics and physico-chemical properties of natural bee honey, being the dynamic or absolute viscosity of the honey a very important property as a quality variable, for the control of the manufacturing process and the design of equipment. It is an edible material that is strongly influenced by temperature, and its physicochemical properties in relation to natural honey, has been reported by several investi-gations (Ahmed et al., 2007; Gleiter et al., 2006; Witczaka et al., 2011, Smanalieva & Senge, 2009) where they have studied the temperature parameters, the cutting speed, the discharge time in capillary viscometers, the composition of the sugar, the moisture content, the water activity, the size of the crystals, etc., however, data on industrialized honey have not been reported until now, and the literature on its rheological properties is unknown.

Therefore, the objective of this study was to characterize its physicochemical and rheological properties of industrialized honey at different temperatures.

2. Materials and Methods

2.1 Analysis of physicochemical properties

For the evaluation of some physicochemical properties of industrialized honey at approxi-mately 20 ºC, the following equipment and procedures were used: For the measurement of the hydrogen potential, a Hanna digital pH with precision ± 0.1 was used The moisture content was calculated using the relationship between the refractive index (AOAC, 1990), the water activity (aW) was measured using the Aqualab-water activity meter equipment (Decagon Devices Inc. Pullman, WA, USA), for the measu-rement of the brix degrees and refractive index, an Atago DBX-55A refractometer brand was used and for the determination of the specific gravity, the pycnometer method was used.

The moisture content was calculated using the relationship between the refractive index (AOAC, 1990), the water activity (aW) was measured using the Aqualab-water activity meter equipment (Decagon Devices Inc. Pullman, WA, USA), for the measu-rement of the brix degrees and refractive index, an Atago DBX-55A refractometer brand was used and for the determination of the specific gravity, the pycnometer method was used.

2.2 Rheological behavior analysis

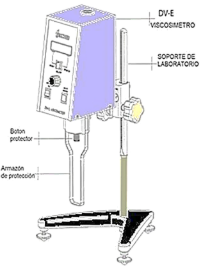

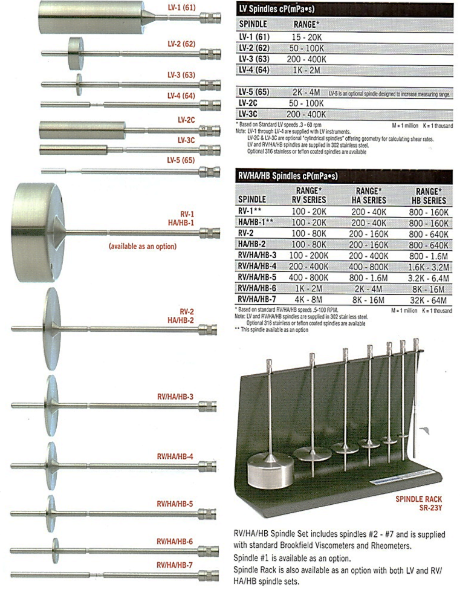

A rotational concentric Brookfield disc viscometer was used for the assessment of the viscosity of industrialized honey as presented in Fig. 1, (Brookfield, 2019), It is a RVDV-E type viscometer that has a set of Spindles (spindles from numbers 2 to 7). In Fig. 2, the set of the equipment spindles is shown. The operating principle of the DV-E is the rotation of the spindle, which is immersed in the fluid. The torque of the spindle is measured, and the equipment measures the absolute or dynamic viscosity (in centipoise: cP or millipascal second: mPa∙s) for each rotation speed used. For the equipment used, the torque at 100% equals 7 187 dynes.cm equivalent to 0,7187 millinewton∙m.

Rotation speeds were calibrated in the rotational viscometer and different values of rotation speed were tested: 0,3, 0,5, 0,6, 1,0, 1,5, 2,0, 2,5, 3, 4, 5, 6, 10, 12, 20, 30, 50, 60 and 100 RPM. In the experiments, a rotation speed and a spindle that gave the highest possible torque should have been used, according to the manufacturer's data, a value that exceeds 40% of torque is recom-mended to perform the reading. The spindle used for all tests was N° 2, a disc type with a diameter of 47 mm. The equipment operated with a thermostatic bath in which the temperature of the fluid bath is set and controlled. The temperature of the equipment operating environment averaged 25 ºC in a relative humidity range of 75-80% during all experiences.

Figure 1. Brookfield RVDV-E type concentric viscometer.

Figure 2. Spindles for type RVDV-E viscometer.

The samples of industrialized honey were purchased in three different locations in the large markets of Metropolitan Lima (North, Center and South), it was verified that the quantities or proportions of its components are not reported on the labels. In 100% of the cases, the honey was packaged in typical flexible plastic containers of 450ml capacity, and they were kept at room temperature in the dark at approximately 20ºC to be analyzed later.

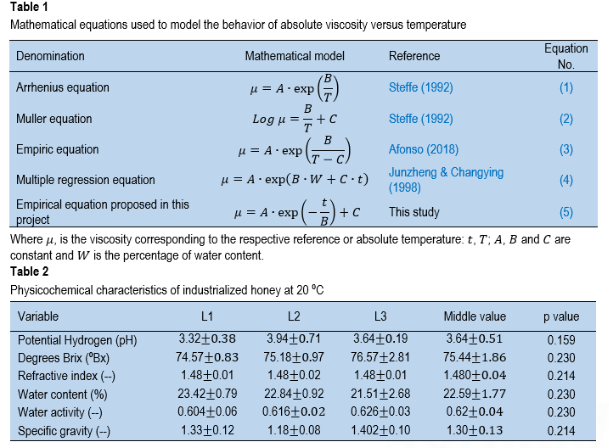

The material tested in the laboratory was subjected to different temperatures of 20, 30, 40, 50 and 60 ºC. According to the test protocol, a Beaker with 500 ml of the sample was used and the spindle was introduced until reaching the mark in the respective spindle. Table 1 presents some equations that serve to model the behavior of absolute viscosity versus temperature.

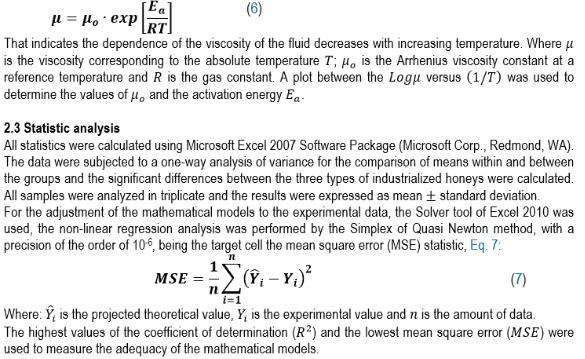

For the determination of the Activation Energy (Ea ) of the industrialized honey, the Arrhenius equation (Jasion et al., 2016) was used, as presented in eq. (6):

3. Results and discussion

3.1 Physicochemical properties

The results of the physicochemical variables of the industrialized honey analyzed from the main markets of metropolitan Lima in the southern, central and northern zones (L1, L2 and L3 products respectively), the mean values are presented in table 2. An analysis was carried out of unidirectional variance within and between the groups of the products and no significant difference was found (for a confidence level of 95%) between the values of the groups of commercial brands tested (p > 0,05).

The water content varies between 20.82 and 24.36%, according to the Codex Alimentarius (1983) for natural honeys this value must be less than or equal to 20%, as this is an industrialized product, the addition of a quantity of water makes it slightly less viscous and more fluid because it has a moisture value greater than 20%. It is observed that the value of the concentration of hydrons varies in the range of 3.13 to 4.15, which defines it as an acid product. The concentration of diluted solids as sucrose was found in the range of 73.58 to 77.30 degrees Brix, due to the additional amount of diluted sugar added to this type of product. The water activity value fluctuated between 0.58 and 0.66 also as a consequence of the presence of sugars that are depressive factors of this physicochemical variable. Both the pH and water activity values found inhibit the presence and growth of microorganisms, which influences the useful lifetime of this type of product.

3.2 Rheological behavior

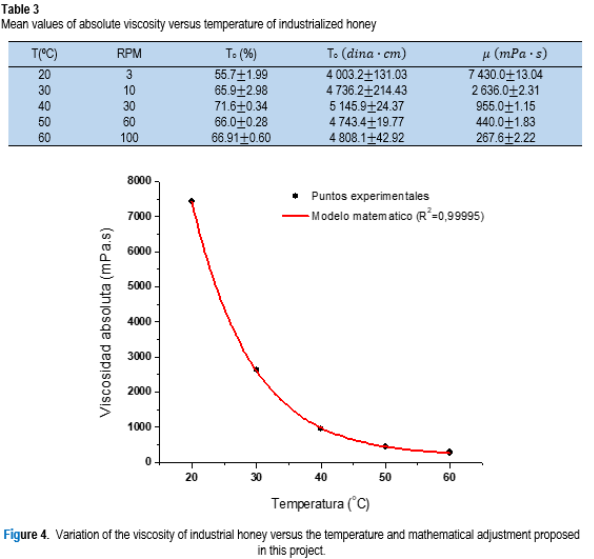

Table 3 shows the mean data corresponding to the industrialized honey tested (T: temperature (ºC); RPM: revolutions per minute; To (%): equipment torque Reading percentage; To: calculated torque (dina * cm) and  Dynamic or absolute viscosity (mPa*s) which represent for the highest average torque of the viscosity read on the equipment.

Dynamic or absolute viscosity (mPa*s) which represent for the highest average torque of the viscosity read on the equipment.

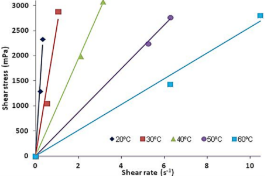

In Fig. 3 the rheogram of the industrialized honey is presented, the relationship between the shear stress and the shear rate is linear, so the analyzed substance follows the behavior of the Newtonian fluid law in the curve of flow, the values of the coefficients of determination being 0.9832; 0.9710; 0.9994; 0.9995 and 0.9876 for the temperatures of 20, 30, 40, 50 and 60 ºC respectively.

Figure 3. Rheogram or flow curve of industrialized honey.

The data in Table 3 have been used to plot the corresponding graph and study the behavior of absolute or dynamic viscosity versus temperature (Fig. 4). It is observed that the relationship of these variables is inversely proportional and non-linear.

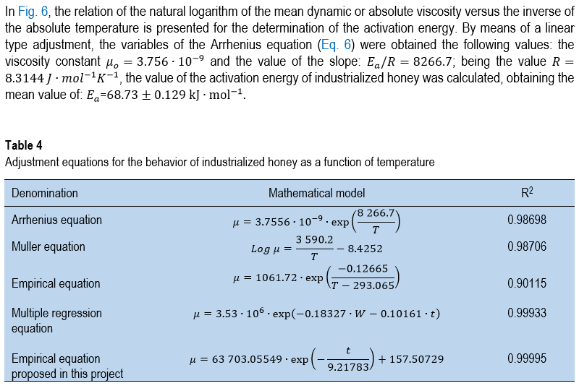

Table 4 shows the mathematical equations developed from Table 2; and the corresponding degree of the coefficient of determination which indicates the efficiency of the adjustment degree of the equation towards the experimental data.

The mathematical model proposed in this research (Table 1, Eq. 5), is an exponential equation of 3 constants, obtaining a satisfactory result, within the range of temperatures tested, resulting in a coefficient of determination of R2 = 0.99995, being this a fairly high value and close to the unit, so this equation is more effective than the other equations proposed to relate the variation of absolute viscosity and temperature. The Junzhen & Changying equation (Table 1, Eq. 4), which takes into account the value of water content and temperature, also fits reasonably well to the experimental data, which for the simulation case the mean moisture content of W = 22.59% was used.

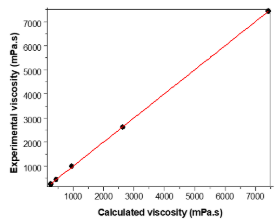

The comparison between the experimental and calculated viscosity values are plotted in Fig. 5, observing a perfect linear correlation between said variables.

Figure 5. The comparison between the experimental and calculated viscosity values

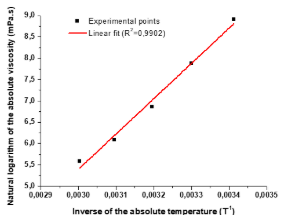

Figure 6. Plot of the logarithm of the mean dynamic viscosity versus the inverse of the absolute temperature.

In Table 5 some values of the activation energy given in the bibliography are presented. The mean value of the activation energy in industrialized honey was similar and slightly lower than the values of natural honeys reported in bibliographic references, this could be due to the low viscosity due to the presence of a high-water content (20.82-24.36%).

The rheological indications determined through the laboratory experiment characterize the technological complexity in the production of food products and constitute one of the most important physicochemical properties in their determination.

In Process Engineering, it is necessary to model the rheological behavior of industrialized honey to understand the manufacturing processes, quality control and guarantee its fluidization in transport systems.

4. Conclusions

The experimental data used in the cases of rheological analysis and the mathematical models applied for the graphs and curve adjustments indicate that they are reliable due to the found values of the coefficients of determination.

The mathematical simulation is made possible with the rheological data obtained experimentally, managing to explain the nature of the flow curves of the food tested and confirms, through data obtained from the bibliography and the laboratory, that there is an inversely proportional and non-linear dependence of the absolute viscosity with temperature, the higher the temperature the viscosity values decrease.

Acknowledgment

The studies were conducted thanks to the support of the Laboratory of Process Engineering and Unit Operations (LIPOU-FIPA) of the Faculty of Fisheries and Food Engineering of the National University of Callao, Constitutional Province of Callao, Lima, Peru.

Table 5

Some values of activation energy

Type of honey | Ea value (kJ/mol) | Reference |

Portuguese natural honey | 71.20-74.50 | Afonso et al. (2018) |

Greek natural honey | 69.10-93.75 | Lazaridou et al. (2004) |

Turkish natural honey | 63.40-78.50 | Kayacier & Karamar (2008) |

Natural honey Barcelona - Spain | 59.00-64.00 | Kabbani et al. (2011) |

Spanish natural honey | 83.80-96.30 | Gómez-Díaz et al. (2009) |

Industrialized honey - Lima Markets - Peru | 68.60-68.86 | This study |

References

Afonso, M., Magalhaes, M., Fernandez, L., Castro, M., & Ramalhosa, E. (2018). Temperature effect on rheological behavior of Portuguese honeys. Pol. J. Food Nutrit. Sci., 68 (3), 10-20.

Ahmed, J., Prabhu, S. T., Raghavan, G. S. V., & Ngadi, M. (2007). Physico-Chemical, Rheological, Calorimetric, and Dielectric Behavior of Selected Indian Honey. Journal of Food Engineering, 79(1), 1207–1213.

Alexander, Y., Malkin, A., & Auraan, I. Rheology (2017). New York, USA; 3th edition, Chentec Publishing.

Alvarez-Suarez, J. M., Tulipani, S., Romandini, S., Bertoli, E., & Battino, M. (2010). Contribution of honey in nutrition and human health: a review. Mediterranean Journal of Nutrition and Metabolism, 3, 15–23.

AOAC (1990): Association of Official Analytical Chemists. Official Methods of Analysis, 15th ed.; Arlington: VA, USA., 96, 38.

Assil, M. L., Sterling, R., & Sporns, P. (1991) Crystal control in processed liquid honey. Journal of Food Science, 56(1), 1034-1041.

Bhandari, B., D´arcy, B., & Chow, S. A (1999). Research note on: Rheology of selected Australian honeys. Journal of Food Engineering, 41(1), 65-86.

Bourne, M. C. (1983) Food Texture and Viscosity: Concept and Measurement. New York, USA; 1st edition, Academic Press.

Brookfield. (2019). Brookfield catalogue. Available in: www.Brookkfieldengineering.com, Consulted on January 15, 2019.

Codex Alimentarius (1983). Proposed draft Codex Standard for Honey (World-wide Standard). (Rome: FAO/WHO) CX/PFV 84/13, also Revisions ALINORM.

Gleiter, R. A., Horn, H., & Isengard, H. D. (2006). Influence of Type and State of Crystallization on the Water Activity of Honey. Food Chemistry, 96(1), 441–445.

Gómez-Díaz, D., Navaza, J. M., & Quintáns-Riveiro, L. C. (2009). Effect of temperature on the viscosity of honey. Int. J. Food Prop., 12, 396–404.

Jasion, A., Ptassek, P. & Basu S. (2016). Advances in Food Rheology and its Applications. New York, USA; 1st edition, Woodhead Publishing.

Junzheng, P., & Chanying, J. (1998). General rheological model for natural honeys in china. Journal of Food Engineering, 36(2), 165-168.

Kabbani, D., Sepulcre, F., & Wedekind, J. (2011) Ultrasound-assisted liquefaction of rosemary honey: Influence on rheology and crystal content. J. Food Eng., 107, 173–178.

Kayacier, A., & Karaman, S. (2008). Rheological and some physicochemical characteristics of selected Turkish honeys. Journal of texture studies, 39(1), 17-27.

Kress, E. R., & Brimelow, C. J. B. (2001). Instrumentation and sensor for the food industry. New York, USA; 3rd edition, Woodhead Publishing.

Lazaridou, A. (2004). Composition, thermal and rheological behaviour of selected Greek honeys. Journal of Food Engineering, 64(1), 9-21.

Mckenna, B. M. (2003). Texture in Food. New York, USA; 1st edition. Woodhead.

Messel, B., Bhandari, B., D´arcy, B., & Caffin, N. (2000). Use of Arrhenius model to predict rheological behaviour in some crystallization honeys. Lebensmittel-Wissenschaft und Technologie, 33(1), 545-552.

Moldenaers, R., & Keunings, R. (1992) Theoretical and Applied Rheology. New York, USA, 1st edition, Elsevier Science.

Popek, S. (2002). A procedure to identify a honey type. Food Chemistry, 79(1), 401-406.

Singh, N., & Bath, D. K. (1997). Quality evaluation of different types of Indian honey. Food Chemistry, 58(1), 129-133.

Slawomir, B., Krzysztof, M., & Bakomiuk J.R. (2016). Rheological properties of some honeys in liquified and crystallized states. J. Apic. Sci., 60(2), 110-120.

Smanalieva, J., & Senge, B. (2009). Analytical and Rheological Investigations into Selected Unifloral German Honey. European Food Research and Technology, 229(1), 107–113.

Sobato, S. F. (2004). Rheology of irradiated honey from Parana region. Radiation physics and Chemistry, 71(1-2), 50-60.

Steffe, J. F. (1992). Rheological Methods in Food Process Engineering. East Lansing, MI, USA; 1st edition Freeman Press.

Steffe, J. F. Daubert, C. R. (2013). Bioprocessing Pipelines. Rheology and Analysis Engineering. East Lansing, MI, USA; 1st edition Freeman Press.

Terrab, A., Diez, M. J., & Heredia, F. J. (2002). Characterization of Moroccan unifloral honeys by their physicochemical characteristics. Food Chemistry, 79 (1), 373-379.

Witczaka, M., Juszczak, L., & Gałkowsk, D. (2011). Non-Newtonian Behaviour of Heather Honey. Journal of Food Engineering, 104(1), 532–537.

The moisture content was calculated using the relationship between the refractive index (AOAC, 1990), the water activity (aW) was measured using the Aqualab-water activity meter equipment (Decagon Devices Inc. Pullman, WA, USA), for the measu-rement of the brix degrees and refractive index, an Atago DBX-55A refractometer brand was used and for the determination of the specific gravity, the pycnometer method was used.