1. Introduction

The demand for plastic polymers is increasing, being present in the composition of a great variety of manufactured products (Junior et al., 2020); Due to COVID-19, its demand has had a significant growth in businesses and homes. When disposing of these products (non-biodegradable waste) they end up in sanitary landfills where if they are not given any reuse treatment, they can cause contamination of the soil and the environment. These products also end up in the seas, rivers, groundwater, or lakes where they accumulate and, as they cannot be degraded, they cause an alteration of the ecosystem.

Plastics derived from crude oil have supplied most of the materials for the manufacture of containers, bags, trays and foams due to their characteristics, such as high product availability, good mechanical, physical and barrier resistance (Silva & Silva, 2016).

Over the years, the accumulation of these plastics in our environment becomes imminent, in which serious eco-environmental problems have been generated due to their low biodegradability (Moo-Tun et al., 2020). Each year up to 8 million tons of plastic are dumped into the oceans (Payne, 2006). Other statistics show that about 300 million tons of plastic waste are generated worldwide per year (Agenda, 2016), of which 50% are single-use plastics (Mora, 2019). But it also has an additional impact because most of these derivatives come from oil, whose extraction and refining processes cause severe environmental impacts (Bourgeois & Llodra, 2009; Lagarón et al., 2016; Razza et al., 2015).

For this reason, it is important to develop sustainable, bio-based containers with properties similar to conventional polymers (Junior et al., 2020) to replace commercial EPS foams and thus be able to minimize the negative impact generated by their use.

Researchers have shown enormous interest in developing biodegradable products that have characteristics similar to polystyrene plastics, using natural polymers such as starch and fibrous inputs in order to generate single-use packaging for food, achieving positive results. In search of these new alternatives, studies have been developed with different inputs, such as cassava starch mixed with sugar cane bagasse, corn husk and malt bagasse (Ferreira et al., 2020), with grape stalks (Engel et al. al., 2019), pineapple peels (Cabanillas et al., 2019), beeswax (Reis de Santana, et al., 2018; Reis et al., 2018) and plasticizers (Stoffel et al., 2019) using thermo-pressing, achieving optimal biodegradable trays. Different starches were formulated such as potato starch combined with beer grains (Ferreira et al., 2019), starch from three native Andean crops such as arracacha, oca and sweet potato (Cruz-Tirado et al., 2019), starch from sugar palm with agar powder (Jumaidin et al., 2016) or cassava bagasse formulated with polyvinyl alcohol (Debiagi et al., 2015), to obtain trays that have properties similar to expanded polystyrene (EPS), in addition to being insulating thermal, low cost (Chiellini, 2009; Ana ES Vercelheze et al., 2012), low density, dimensional stability and high resistance to humidity (Kaisangsri et al., 2012; Xing et al., 2013). Agroindustrial residues generated by industries such as sugarcane bagasse and asparagus shells are also used to optimize the properties of trays made with sweet potato starch (Cruz-Tirado et al., 2019).

All these investigations show that it is possible to obtain food packaging from mixtures of starch, fibers and water through processes such as thermo-pressing.

In this study, the starch of a tuber that is produced in the Peruvian highlands with a production potential that is growing year by year (Coca & Exterior, 2018), the oca, was used, which mixed with natural fiber from banana leaves and achira (They are mostly used to wrap different foods or pack typical foods) (Piedrahita, 2012) improve their mechanical properties and reduce their sensitivity to humidity (Espina, 2016). These raw materials, easy to obtain, cheap, and non-toxic, contribute to the protection of the environment (Ruggiero et al., 2006), giving it an additional use.

Therefore, the objective of the present work was to evaluate the influence of the proportion of vegetable fibers of banana (Musa paradisiaca) leaves and achira (Canna indica) with oca (Oxalis tuberosa) starch on the properties of biodegradable trays.

2. Material and methods

2.1. Materials

For the elaboration of the biodegradable trays, oca variety squash (29% amylose and 71% amylopectin) obtained from the province of Chota, Cajamarca was used, which was cut into 2 cm pieces and crushed in a food processor (Model I5, Industrias Maguiña) for 5 minutes to reduce its particle size. The resulting paste was filtered through < 300 µm stainless steel sieves. The resulting suspension of starch + water stood at 4 °C for 24 h to recover the starch. The liquid supernatant was discarded, the resulting starch fraction was washed 3 times by resuspension in water. Finally, it was dried at 37 °C for 48 hours in a Memmert oven. Finally, the starch was dried, ground and sieved until obtaining native starch with a particle size <106 µm (Sieve No. 140).

To obtain vegetable fibers, banana and achira leaf sheets obtained from the city of Chota, Santa Mónica sector, Cajamarca were used, which were cleaned and cut before being placed in an oven at a temperature between 60-70 °C for 72 hours. The dry leaves were placed in a mill for 3 minutes and 30 seconds and then they were sieved until obtaining fibers with a particle size <180 µm (Sieve No. 80). Starch and vegetable fibers were extracted at the Agroindustrial Processes Engineering Laboratory of the National University of Trujillo (Trujillo, Peru).

2.2. Production process of biodegradable trays

The starch and vegetable fiber trays were obtained using different formulations based on previous results in trial error tests (unpublished). Table 1 shows the concentrations of each component used in the preparation of the biodegradable trays. 3 different fiber addition formulations were determined in concentrations of 2.5%, 5% and 7.5%, coded as W1, W2 and W3 respectively.

For the formulations with the vegetable fibers of the banana and achira leaves, they were coded with the letters P and A respectively. With these formulations, 6 different treatments were obtained plus a control treatment that will make it possible to compare the effect of the percentages of fibers added in the trays made with goose starch. The amount of water was adjusted in order to maintain the viscosity of the mixture, allowing to obtain complete trays.

The formulated concentrations of the fibers, starch and water were mixed with a mechanical stirrer (Oster, China) for 5 minutes at 1500 rpm. Immediately, the 46 grams of each formulation were homogeneously placed inside the lower teflon platform (dimensions: 270 mm x 200 mm x 25 mm, thickness 3 mm) of a thermocompression molding mechanism (RELES SRL, PHI / dL, Peru) in which the lower and upper plate of the mechanism were closed by means of a hydraulic system with a pressure of 60 bar at an average temperature of 200 °C for 90 seconds (Figure 1). Finally, each tray was removed from the thermopress and stored for seven days (60% relative humidity and 25 °C) to subsequently perform the characterization analyzes.

2.2. Characterization of the trays

Production performance

The percentage of whole trays produced at the end of each period represent the efficiency of the process for the formulations (Mello & Mali, 2014).

Color parameters

The color of the biodegradable trays was determined using a JZ-300 colorimeter (Shenzhen Kingwell Instrument Co. Ltd, China.

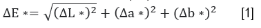

The range of the color parameters was as follows: L* = 0 to 100 (black to white); a* (values negative values (-a) indicate greenness and positive values (+a) redness) and b* (negative values (-b) indicate blue and positive values (+b) yellowness) (Salgado et al., 2008). performed with the white standard plate and the following coordinates were obtained: L = 89.8; a = 1.9 and b = -4.9. Five measurements were made for each formulation, and these values were averaged to be reported. In addition, taking into account the Equation 1, the total color difference (ΔE) was calculated for each formulation.

Thickness and density

A DC051 stainless steel digital vernier (0 - 150 mm) (MAGTOTO, China) was used to measure the thickness of the trays; The reported values are the averages of 5 measurements made to each of the 7 formulated trays.

According to the method used by Shogren et al. (1998), the density (g/cm3) of each sample was calculated based on its mass (g) and volume (cm3). The samples (width 25 mm; length 100 mm) were weighed, and their volume was calculated by multiplying their measurements (thickness x width x length). For each formulation, 5 repetitions were carried out, these values were averaged to inform the density results.

Moisture content and water absorption capacity (WAC)

Following the method of Cruz-Tirado et al. (2019), approximately 1 gram of each tray (sample) was placed inside the moisture analyzer with MX-50 halogen lamps (A&D Company, Limited, Japan) at 105 °C to determine its moisture content.

To measure the water absorption capacity of the trays during immersion, the technical standard NBR NM 535 (Técnicas, 1999) was used. Samples of the trays formulated with dimensions of 50 mm x 25 mm were cut and then weighed (𝑚𝑖), immersed in distilled water (25 ± 1 °C) for 30 seconds and weighed again (𝑚𝑓). Excess water was removed with tissue paper. The following equation (2) was used to determine the water absorption capacity:

WAC =((mf -mi)/mi)*100 [2]

Mechanical properties

The trays were subjected to mechanical stress (tension and perforation) through the TA.HDplus texture analyzer (Stable Macro Sistems, United Kingdom) with a 50 N cell load. The first test carried out was carried out according to the ASTM D8S8 standard method where rectangular samples of 25 mm x 100 mm were analyzed, separated by 80 mm between the grips and 2 mm/s of crossing speed (ASTM, 2016; Vercelheze et al., 2012). During the extension, stress-strain curves were recorded, specifying the tensile strength (MPa) and elongation (%). The values reported for each formulation are the averages of 3 trials. The maximum tensile stress prior to breaking of the material expresses the tensile strength and elongation registered up to the moment of failure, which represents the percentage of elongation (equations 3 and 4, respectively); where F: maximum tensile force; A: cross-sectional area; Lo: initial calibration length; and L: final length.

Tensile strength = F/A [3]

Elongation =(L-Lo)/Lo [4]

The drilling test was performed on square samples (50 mm per side), using the HDP / 90 platform with the HDP/CFS accessory and the P/0.25S sphe-rical specimen (stainless steel). The specimen had a displacement of 25 mm at a speed of 1.0 mm/s for each test. Puncture resistance (N) and deformation (mm) were determined.

Fourier transform infrared spectroscopy

Tray samples with dimensions of 25 x 25 mm2 were used, the Fourier-infrared transform (FTIR) analysis was performed with a Nicolet iS50 FTIR (Thermo Fisher, Germany), with a resolution of 4 cm-1 and in the range 4000–500 cm-1. 16 scans per spectrum accumulated in absorbance mode.

Statistical analysis

To compare the 7 formulations that were elaborated in this study and determine significant differences between these treatments, the analysis of variance (one-way ANOVA) was used and later the Tukey test with a level of significance established at p < 0.05. The analyzes were carried out in the statistical software SPSS (International Business Machines Corporation, USA).

3. Results and Discussion

Production performance

The production of the biodegradable trays obtained yields between 40 to 100% approxi-mately. 29 trial error trials were carried out, from which 2 whole and intact trays were obtained for each treatment worked.

A maximum production yield (100%) was obtained for the trays of the treatments PW1, AW1 and AW1. While for the PW2, PW3 and AW3 treatments, yields of 50%, 40% and 66.7% were obtained, respectively. The trays that have lower percentages of fibers from either banana leaf or achira had a higher yield.

The viscosity of the formulated mixture increases with the addition of natural fiber and produces a higher resistance to expansion, as well as higher concentrations of fiber can cause an inadequate conformation of the matrix while the tray is manufactured in the thermopress (Shogren et al., 1998). These points explain the weak points in the foam trays (Cinelli et al., 2006; Lawton et al., 2004), despite the fact that more water was incorporated to homogenize and maintain the fluidity of the mixture after one hour. of mixing.

Color parameters

Control trays containing only oca starch were white (Figure 2). The trays with addition of fiber showed a reddish and yellowish color compared to the control tray, which is consistent with the results in Table 2 showing that the values of a* and b* increase significantly (p ≤ 0.05). The color para-meters shown in the tray without the addition of fibers (control) were: L* = 70.16; a* = 0.8 and b* = 0.18; and the trays with added fiber presented: L* = 51.6 to 61.9, a* = 1.2 to 2.7 and b* = 6.3 to 14.5.

While the percentage of addition of the fibers used increases, the L* value decreases, which in turn led to an increase in ΔE (Table 2). This could be due to the presence of lignin, associated with the presence of phenolic compounds (Ramírez & Enríquez, 2015), giving a darker color to the higher concentration trays.

This darker appearance of the trays when adding vegetable fibers is also a product of the Maillard reaction due to the reaction between proteins and carbohydrates product of temperature and pressure during the thermoforming process (Salgado et al., 2008). Various studies such as those of (Cruz-Tirado et al., 2017; Machado et al., 2017; Matsuda et al., 2013) have verified this hypothesis, reporting that the addition of fiber to the foam reduces the brightness values of incomposited starch (Mello & Mali, 2014; Vercelheze et al., 2013).

The parameter a* increased as more fiber was added to the mixture, and significant differences were also found between the control and the other formulations. This could be due to the presence of a biopolymer present in plant fibers such as lignin found in the middle sheet of the cell wall and in the layers of the cell wall of the fibers (Marcelo et al., 2013; Of et al., 2005), which provides a more pronounced redness to the PW3 and AW3 formulations, which have a higher percentage of fibers in their formulation. For the parameter b* (yellow/blue coordinates) the values were increased according to the incorporation of vegetable fiber in the formulation, significant differences were obtained according to the Tukey test (p < 0.05) between the formulations with different percentages but it was found similarity in the formulations of the same percentage of different fiber, this is due to the fact that in both fibers an approximate amount of lignin is found in the structure of the leaves used (Marcelo et al., 2013).

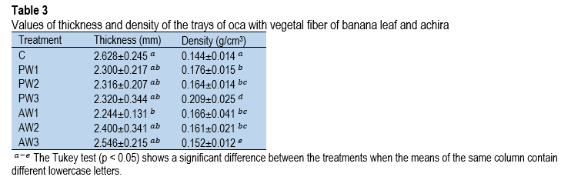

Thickness and density

Table 3 shows the summary results for the thickness and density of the biodegradable trays. The thickness and density of the control tray (C) were 2.628 mm and 0.144 g/cm3, respectively. For the thickness there was a variation between 2.244 to 2.546 mm. These values are in the range of values reported by various investigations such as that of (Cabanillas et al., 2019) where cassava starch trays were obtained by adding pineapple rind with values between 2.616 and 2.558 mm thick. Also, Cruz-Tirado et al. (2017) reported values between 2.485 and 2.602 mm in thickness of trays made with goose starch plus asparagus peel fiber and sugar cane bagasse.

The thickness value increases by adding a greater percentage of the fiber used, but the one that increases the most is the AW3 tray, which has 7.5% fiber from the achira sheet, with a value close to the control value of 2.546 mm. This may be due to the fact that, by adding fiber to the starch tray, it interferes with the foaming and expansion process of the starch, reducing starch-starch interactions and probably weakening the structure (Kaisangsri et al., 2014; Tirado, 2017). However, the Tukey test (p < 0.05) showed that only the thickness of the AW1 tray decreased significantly compared to the control tray (C).

The density values ranged from 0.152 to 0.209 g/cm3, for the trays made with achira leaf fiber, the values decreased when the percentage of fiber addition increased, a different case than the trays made with banana leaf fiber that increases their density by adding a higher percentage of fiber. Tukey's test (p < 0.05) showed significant differences between the formulations with a slight decrease in the density values (g/cm3). The values of this study were higher compared to the density presented by commercial EPS trays with a value of 0.041 g/cm3 of density (Tirado, 2017), to that of (Mello & Mali, 2014) where they reported values of trays made with cassava starch and malt bagasse between 0.415-0.450 g/cm3 of density, research by (Matsuda et al., 2013) reported higher densities in cassava starch trays reinforced with nanoclays (0.2809 - 0.3067 g/cm3 of But it was also possible to find trays with values similar to those reported by other authors such as that of (Vercelheze et al., 2012) with values between 0.1941-0.2996 g/cm3 or that of (Mali et al., 2010) that I report values between 0.20 - 0.33 g/cm3 of foam trays made of cassava starch and vegetable fibers.

Moisture content and water absorption capacity (WAC)

Moisture content and water absorption capacity (WAC)

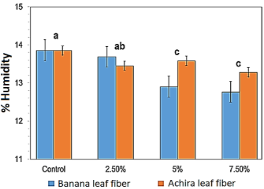

The humidity of the control tray was 13.855% which decreased as the percentage of fiber used increased, this behavior can be observed in Figure 3. Significant differences were found when applying the Tukey test (p < 0.05) between the humidity values of the control trays and the percentages of 5% and 7.5% of vegetable fiber addition. A decreasing trend can be observed in the values, especially of the trays that added banana leaf fiber, this slight behavior can be attributed to the hydrophobic characteristic of the fiber (Salvador et al., 2008), and the increase concentration in the formulations, reducing the affinity of the trays for humidity.

Figure 3. Moisture from oca starch trays mixed with banana leaf fiber and achira.

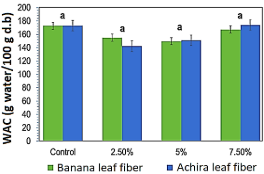

The values of the water absorption capacity of the elaborated trays vary between 142.29 to 173.99 g water/100 g d.b. (Figure 4). For the control tray, its value was 172.94 g water/100 g d.b.

No significant differences are shown between the percentages according to the Tukey test (p < 0.05). However, in the trays where 2.5% and 5% of vegetable fiber were added, there was a small decrease in the values of the water absorption capacity (WAC). This effect could be due to the cohesive structure presented by these trays due to the presence of cellulose found in vegetable fibers reducing WAC (Bénézet et al., 2012; Guan & Hanna, 2006). A slight increase in the WAC for the formulations with 7.5% percentage (PW3 and AW3) this is possibly due to an interference of the fiber in the structure due to the high concentration, which destabilizes the matrix and facilitates the movement of water inside the tray.

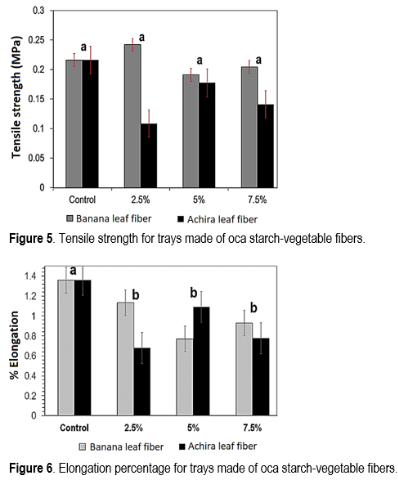

Mechanical properties

The tensile strength for the control tray was 0.21 MPa, as can be seen in Figure 5, for the trays made with banana fiber the values decreased slightly when the addition percentage was increased, probably due to the high percentage of fiber hindering the expansion during thermoforming, producing a discontinuity between the starch chains and later exposing this weakness of the trays (Cruz-Tirado et al., 2019; Salgado et al., 2008), unlike the achira fiber that had an increase when adding a higher percentage because the presence of the fiber provides a better resistance to the tray (Asim et al., 2015). Despite all these results, the Tukey test (p < 0.05) did not show significant differences between the treatments or type of fiber used.

Figure 4. Water absorption capacity (WAC) for oca starch trays mixed with banana leaf fiber and achira.

The percentage of elongation of the control tray was 1.36 and the values of the fiber treatments were between 0.68% to 1.13% (Figure 6), values lower than those of the commercial expanded polystyrene (2.82%) (Cabanillas et al., 2019) , for the trays made with banana fiber, the values decreased when the percentage of addition was increased, probably due to an interference of fiber agglomerates in the matrix (Cruz-Tirado et al., 2019), producing trays with less elastic capacity, when Contrary to the achira fiber, which had an increase when adding a higher percentage due to the fact that there is a strong interaction between starch-fiber in low concentrations that can probably be attributed to the fiber size, obtaining trays with a higher percentage of elongation (Salgado et al., 2008). The Tukey test (p < 0.05) showed significant differences between the treatments, showing that the percentage of fiber addition has an influence on the elastic capacity.

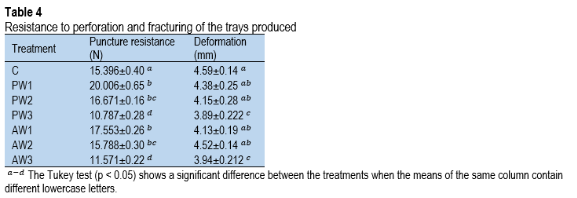

The resistance to perforation for the control tray was 15.396 ± 0.40 N, a value that is well below the value reported by (Cabanillas et al., 2019) of the EPS with 38 N of resistance to perforation. The values of the formulations with the highest percentage of fiber (7.5%) decreased significantly according to the Tukey test (p < 0.05). For the formulations that used banana leaf fiber, slightly higher values were obtained than those of achira leaf because they have a better adhesion with goose starch, having as the best treatment the PW1 tray (2.5% of vegetable fibers) with a value of 20,006 N.

The decrease in resistance could be due to the presence of fiber that weakened the cohesion between the starch structures, decreasing the expandability and producing discontinuity in the polymeric matrix (Cruz-Tirado et al., 2019; Salgado et al., 2008). The values obtained are well below EPS trays (commonly used), this could be associated with the low amount of cellulose present in the fibers used and the low solubility in water, giving the trays less resistance (Bénézet et al., 2012; Cabanillas et al., 2019; Properties, 2014).

The deformation of the formulated trays had a similar behavior with the resistance values (Table 4) to perforation where the Tukey test (p < 0.05) determined that when adding a higher percentage of fiber, the deformation value decreased slightly with significant differences, obtaining AW2 as the best treatment with 4.52 mm of deformation. The reduction of this property could be associated with the low water absorption capacity, which functions as a plasticizer within the proposed formulations, making the biodegradable trays less deformable (Grossmann et al., 2006).

FTIR spectroscopy

Figure 7 shows the FTIR spectra obtained from the treatments performed, in all the samples the same spectral behavior was manifested. An absorption band at 3310 cm-1 is presented in all samples, which may indicate the presence of OH groups (Cabanillas et al., 2019) and the existence of H-bonding interactions between the components of the tray during their process. of thermoforming (Vercelheze et al., 2012). The bands present between 2920 and 2870 cm-1 are associated with the stretching of the CH molecule in the -CH2 and -CH3 groups and the conjugated bending vibrations of H- molecules. C – H and –C – O – H (Maniglia & Tapia-Blácido, 2016; Vercelheze et al., 2012). In addition, the bands present at 1630 cm-1 indicates an ester bond (Matsuda et al., 2013), which could be attributed to an intermolecular hydrogen interaction between water and starch, the fiber. The bands assigned to the carbohydrate vibrations appeared in the region between 1210 and 575 cm-1, which are associated with the stretching of the COH bond (glycosidic bond) (Pelissari et al., 2012), and could be due to the presence of starch molecules in the samples. Figure 7 shows that an increase in the concentration of the fibers used decreases the intensity in all the mentioned bands, which could indicate a weak interaction between the starch chains (Vercelheze et al., 2012) due to the lower proportion of starch in the trays formulated.

4. Conclusions

This research demonstrated the possibility of making biodegradable trays of goose starch and fiber from vegetable leaves (banana and achira), a biodegradable product with a high-production tuber, highly appreciated in the Peruvian highlands and with vegetable leaves that are only used in a handcrafted. The addition of fiber in different concentrations (2.5%, 5% and 7.5%), generated trays with adequate expansion with homogeneously distributed fibers, acceptable appearance, low luminosity and a yellowish greenish color. As fiber concentrations increased, the ability to absorb water increased, however, moisture content, resistance to perforation and fracturing decreased. In general, the tray with 2.5% banana leaf fiber (PW1) obtained the best results in this study, this amount and type of fiber reduced the capacity to absorb, increased the percentage of elongation, the tensile strength and is the tray with the highest puncture resistance. These trays can be used to pack dry food with a short shelf life and can be a viable alternative to replace the Styrofoam trays we use daily.

In future work, the modification of starch should be prioritized, increasing the percentages of natural fibers to observe the behavior of the trays and evaluate the chemical composition of the fibers.

Acknowledgment

This research was funded by the "Universidad Nacional Autónoma de Chota" through the “IV Concurso de Investigación Aplicada a Emprendimiento e Innovación Start Up 2018” by Resolution No. 373-2018-C.O./UNACH of July 11, 2018, to which we thank enormously. Also, special thanks to Dr. Raúl Siche, from the National University of Trujillo, for advising him and providing us with access to the “Laboratorio de Ingeniería de Procesos Agroindustriales”, where the containers were made by thermo-pressing.

References

Agenda, I. (2016). The New Plastics Economy Rethinking the future of plastics. January.

Asim, M., Abdan, K., Jawaid, M., Nasir, M., Dashtizadeh, Z., Ishak, M. R., Hoque, M. E., & Deng, Y. (2015). A review on pineapple leaves fibre and its composites. International Journal of Polymer Science, Article ID 950567.

ASTM. (2016). Tensile properties of paper and paperboard ( using constant rate of elongation apparatus) (Revision of T 494 om-01).

Bénézet, J., Stanojlovic-davidovic, A., Bergeret, A., Ferry, L., & Crespy, A. (2012). Mechanical and physical properties of expanded starch , reinforced by natural fibres. Industrial Crops & Products, 37(1), 435-440.

Bourgeois, D. M., & Llodra, J. C. (2009). Strategies to promote better access to over the counter products for oral health in Europe: a Delphi survey. International Dental Journal, 59(5), 289-296.

Cabanillas, A., Nuñez, J., Cruz-Tirado, J. P., Vejarano, R., Tapia-Blácido, D. R., Arteaga, H., & Siche, R. (2019). Pineapple shell fiber as reinforcement in cassava starch foam trays. Polymers and Polymer Composites, 27(8), 496-506.

Chiellini, E. P. C. and V. I. I. (2009). Environmentally Compatible Foamed Articles Based on Potato Starch, Corn Fiber, and Poly(Vinyl Alcohol. Biomedical & Environmental Applications, 16-32.

Cinelli, P., Chiellini, E., Lawton, J. W., & Imam, S. H. (2006). Foamed articles based on potato starch, corn fibers and poly(vinyl alcohol). Polymer Degradation and Stability, 91(5), 1147-1155.

Coca, C. De, & Exterior, C. (2018). Compendio estadistico Peru 2018-Agrario.

Cruz-Tirado, J. P., Siche, R., Cabanillas, A., Díaz-Sánchez, L., Vejarano, R., & Tapia-Blácido, D. R. (2017). Properties of baked foams from oca (Oxalis tuberosa) starch reinforced with sugarcane bagasse and asparagus peel fiber. Procedia Engineering, 200, 178-185.

Cruz-Tirado, J. P., Vejarano, R., Tapia-Blácido, D. R., Barraza-Jáuregui, G., & Siche, R. (2019). Biodegradable foam tray based on starches isolated from different Peruvian species. Interna-tional Journal of Biological Macromolecules, 125, 800-807.

Cruz-Tirado, Jam Pier, Vejarano, R., Tapia-Blácido, D. R., Angelats-Silva, L. M., & Siche, R. (2019). The addition of sugarcane bagasse and asparagus peel enhances the properties of sweet potato starch foams. Packaging Technology and Science, 32(5), 227-237.

Debiagi, F., Marim, B. M., & Mali, S. (2015). Properties of Cassava Bagasse and Polyvinyl Alcohol Biodegradable Foams. Journal of Polymers and the Environment, 23(2), 269-276.

Engel, J. B., Ambrosi, A., & Tessaro, I. C. (2019). Development of a Cassava Starch-Based Foam Incorporated with Grape Stalks Using an Experimental Design. Journal of Polymers and the Environment, 27(12), 2853-2866.

Espina, M. (2016). Scientia Agropecuaria Propiedades mecánicas de bandejas elaboradas con almidón de especies vegetales nativas y fibras de residuos agroindustriales. 7(2), 133-143.

Ferreira, A., Martins, J., Carvalho, L., & Magalhães, F. (2019). Biosourced Disposable Trays Made of Brewer’s Spent. Polymers, 11(5), 1-14.

Ferreira, D. C. M., Molina, G., & Pelissari, F. M. (2020). Biodegradable trays based on cassava starch blended with agroindustrial residues. Composites Part B: Engineering, 183, 107682.

Grossmann, E., Garcı, M. A., Martino, M. N., & Zaritzky, N. E. (2006). Effects of controlled storage on thermal , mechanical and barrier properties of plasticized films from different starch sources. 75, 453-460.

Guan, J., & Hanna, M. A. (2006). Selected morphological and functional properties of extruded acetylated starch - cellulose foams q. 97, 1716-1726.

Jumaidin, R., Sapuan, S. M., Jawaid, M., Ishak, M. R., & Sahari, J. (2016). Characteristics of thermoplastic sugar palm Starch/Agar blend: Thermal, tensile, and physical properties. International Journal of Biological Macromolecules, 89, 575-581.

Junior, I. T., Dal Bosco, T. C., Bertozzi, J., Michels, R. N., & Mali, S. (2020). Biodegradability assessment of starch/glycerol foam and poly(butylene adipate-co-terephthalate)/starch film by respirometric tests. Brazilian Journal of Food Technology, 23, 1-15.

Kaisangsri, N., Kerdchoechuen, O., & Laohakunjit, N. (2012). Biodegradable foam tray from cassava starch blended with natural fiber and chitosan. Industrial Crops and Products, 37(1), 542-546.

Kaisangsri, N., Kerdchoechuen, O., & Laohakunjit, N. (2014). Characterization of cassava starch based foam blended with plant proteins , kraft fiber , and palm oil. Carbohydrate Polymers, 110, 70-77.

Lagarón, J. M., López-Rubio, A., & José Fabra, M. (2016). Bio-based packaging. Journal of Applied Polymer Science, 133(2), Edit.

Lawton, J. W., Shogren, R. L., & Tiefenbacher, K. F. (2004). Aspen fiber addition improves the mechanical properties of baked cornstarch foams. Industrial Crops and Products, 19(1), 41-48.

Machado, C. M., Benelli, P., & Tessaro, I. C. (2017). Sesame cake incorporation on cassava starch foams for packaging use. Industrial Crops and Products, 102, 115-121.

Mali, S., Debiagi, F., Grossmann, M. V. E., & Yamashita, F. (2010). Starch, sugarcane bagasse fibre, and polyvinyl alcohol effects on extruded foam properties: A mixture design approach. Industrial Crops and Products, 32(3), 353-359.

Maniglia, B. C., & Tapia-Blácido, D. R. (2016). Isolation and characterization of starch from babassu mesocarp. Food Hydrocolloids, 55, 47-55.

Marcelo, E., Aplicaciones, E. Y., Despolimerización, M. D. E., & La, P. (2013). Lignin, structure and applications : depolymerization methods for.

Matsuda, D. K. M., Verceheze, A. E. S., Carvalho, G. M., Yamashita, F., & Mali, S. (2013). Baked foams of cassava starch and organically modified nanoclays. Industrial Crops and Products, 44, 705-711.

Mello, L. R. P. F., & Mali, S. (2014). Use of malt bagasse to produce biodegradable baked foams made from cassava starch. Industrial Crops and Products, 55, 187-193.

Moo-Tun, N. M., Iñiguez-Covarrubias, G., & Valadez-Gonzalez, A. (2020). Assessing the effect of PLA, cellulose microfibers and CaCO3 on the properties of starch-based foams using a factorial design. Polymer Testing, 86(December 2019).

Mora, J. E. G. (2019). Plásticos De Un Solo Uso. In Tecnology for Enviroment (Vol. 227, Issue 5).

Of, U., Waste, P., The, F. O. R., & Of, P. (2005). Fermentación en estado sólido con el hongo Lentinus crinitus. 13-20.

Payne, A. (2006). Key debates in new political economy. Key Debates in New Political Economy, 1-206.

Pelissari, F. M., Andrade-Mahecha, M. M., Sobral, P. J. D. A., & Menegalli, F. C. (2012). Isolation and characterization of the flour and starch of plantain bananas (Musa paradisiaca). Starch/Staerke, 64(5), 382-391.

Piedrahita, S. D. (2012). Las hojas de las plantas como envoltura de alimentos.

Properties, T. (2014). Native Cellulose: Structure, Characterization and Thermal Properties. 6105-6119.

Ramírez, J. H., & Enríquez, M. K. (2015). Remoción de plomo (II) usando lignina obtenida a partir del procesamiento del seudotallo de plátano. Acta Agronomica, 64(3), 209-213.

Razza, F., Innocenti, F. D., Dobon, A., Aliaga, C., Sanchez, C., & Hortal, M. (2015). Environmental profile of a bio-based and biodegradable foamed packaging prototype in comparison with the current benchmark. Journal of Cleaner Production, 102, 493-500.

Reis, M. O., de Santana, H., Bilck, A. P., Grossmann, M. V. E., & Yamashita, F. (2018). Characterization of coated biodegradable trays by spectroscopic techniques. Industrial Crops and Products, 112(March 2017), 511-514.

Reis, M. O., Olivato, J. B., Bilck, A. P., Zanela, J., Grossmann, M. V. E., & Yamashita, F. (2018). Biodegradable trays of thermoplastic starch/poly (lactic acid) coated with beeswax. Industrial Crops and Products, 112(December 2017), 481-487.

Ruggiero, R., Machado, A. E. H., Hoareau, W., & Gardrat, C. (2006). Photodegradation of Sugarcane Bagasse Fibers. Influence of Acetylation or Grafting UV-Absorber and/or Hindered Nitroxide Radical on their Photostability. 17(4), 763-770.

Salgado, P. R., Schmidt, V. C., Molina Ortiz, S. E., Mauri, A. N., & Laurindo, J. B. (2008). Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. Journal of Food Engineering, 85(3), 435-443.

Salvador, M. D., Amigó, V., Nuez, A., Sahuquillo, O., Llorens, R., Martí, F., & Tecnológico, I. (2008). Caracterización de fibras vegetales utilizadas como refuerzo en matrices termoplásticos. 1-4.

Shogren, R. L., Lawton, J. W., Doane, W. M., & Tiefenbacher, K. F. (1998). Structure and morphology of baked starch foams. 39(25), 6649-6655.

Silva, P. C., & Silva, W. A. (2016). Caracterização Das Soluções Filmogênicas De Amido De Fruta-Pão (Artocarpus Altilis) E Dos. 1-6.

Stoffel, F., Weschenfelder, E. F., Camassola, M., Piemolini-Barreto, L. T., & Zeni, M. (2019). Influence of Plasticizers in Enzymatic Degradation and Water Resistance of Starch Foam Trays Obtained by Thermal Expansion. Journal of Polymers and the Environment, 27(4), 739-746.

Técnicas, A. B. de N. (1999). NBR NM ISO 535: Papel e Cartao: Determinaçao da capacidade de absorçao de água.

Tirado, L. J. P. C. (2017). Influencia de la temperatura y tiempo de termoformado en las propiedades mecanicas de bandejas de almidón y fibras vegetales.

Vercelheze, Ana E S, Fakhouri, F. M., Dall, L. H., Urbano, A., Youssef, E. Y., & Yamashita, F. (2012). Properties of baked foams based on cassava starch , sugarcane bagasse fibers and montmorillonite. Carbohydrate Polymers, 87(2), 1302-1310.

Vercelheze, Ana Elisa S., Oliveira, A. L. M., Rezende, M. I., Muller, C. M. O., Yamashita, F., & Mali, S. (2013). Physical Properties, Photo- and Bio-degradation of Baked Foams Based on Cassava Starch, Sugarcane Bagasse Fibers and Montmorillonite. Journal of Polymers and the Environment, 21(1), 266-274.

Xing, Z., Wang, M., Du, G., Xiao, T., Liu, W., Qiang, D., & Wu, G. (2013). Preparation of microcellular polystyrene/polyethylene alloy foams by supercritical CO2 foaming and analysis by X-ray microtomography. Journal of Supercritical Fluids, 82, 50-55.